3/8 steel cutting advise

#1

Registered User

Thread Starter

3/8 steel cutting advise

So I'm using some 3/8 steel to make my own shackles . I've used my snap on angle grinder with 3" cutoff wheel to cut 3/8 before and it worked ok , but for smaller projects. I'm looking to cut out 8 shackles 2in wide 7in long. I got a big peice of 3/8 for nothing so I'm gonna use it rather than buying smaller peices to work with. I don't have a plasma , or a band saw. So I'm looking into a better and faster way to rip through this. Any help would be appreciated. Thanks

#2

If you don't have a plasma or band saw your pretty much stuck with the zip wheels. I would rather use a 4.5" than 3"....

If that's all ya got though looks like your work is cut out for ya..... (pun intended)

If that's all ya got though looks like your work is cut out for ya..... (pun intended)

#6

The good old sweat and busted-knuckles hack saw works great for such a task.

Slow steady full length strokes only using down pressure on forward stroke, lifting slightly on return.

After figuring grinding time...you can do this faster than a torch or bargain basement plasma.

If you had access to a real plasma, it may be different. There is nothing on TV anyhow lol.

Slow steady full length strokes only using down pressure on forward stroke, lifting slightly on return.

After figuring grinding time...you can do this faster than a torch or bargain basement plasma.

If you had access to a real plasma, it may be different. There is nothing on TV anyhow lol.

#7

Registered User

Join Date: Jun 2010

Location: longmont, co

Posts: 69

Likes: 0

Received 0 Likes

on

0 Posts

you might be better off having a shop dice them up into the rough shape you want, then you can do the drilling and grinding/shaping with your tools. should save you time and maybe money (cut off wheels are pretty cheap, but they add up fast)

Trending Topics

#8

Registered User

iTrader: (1)

They make zip discs for at least 7" I know I have some.

Would have been easier to just get a piece of 3/8"x2" x?? then all you would need to just zip the 2" length drill your holes and done.

Sometimes free is not always the cheapest in the long run.

Oxy-fuel cutting if your doing it correct you might need to just clean up with a flap disc if you need more than that . You need more practice or be shown how to use the torch.

Electric / air I guess it depends on just what one has to work with.

Would have been easier to just get a piece of 3/8"x2" x?? then all you would need to just zip the 2" length drill your holes and done.

Sometimes free is not always the cheapest in the long run.

Oxy-fuel cutting if your doing it correct you might need to just clean up with a flap disc if you need more than that . You need more practice or be shown how to use the torch.

Electric / air I guess it depends on just what one has to work with.

#9

Contributing Member

iTrader: (3)

If you have a table saw, I used to use a 10" cutoff wheel in my table saw to cut steel. Works well but you need to make sure the inside of clear of saw dust to prevent it catching on fire. Or use a grinder with cutoff wheel and if you cut about 1/8" deep on both sides, you can snap off the rest bending it back and forth a few times.

#10

Registered User

Thread Starter

Those are all great suggestions. But I don't have acces to a plasma/ band saw , don't wanna pay a shop to cut them down or to go out and buy 3/8x2 , that would defeat the purpose of getting a slab of 3/8 big enough to make all my shackles for nothing . I think my best bet would buy a 4-6" cut off wheel for my electric grinder. I may also try the hack saw but dang that seems rough. If I were to go out and buy the material then yes 3/8 x2" would be easy but I'm working with what I got for nothing. Thanks for all the replies.

Last edited by 775Toy; 12-27-2011 at 06:21 PM.

#12

Registered User

Thread Starter

My labor is free , I have a family and other obligations but again my time is free and this build is on the budget side. If I were to pay a shop 40$ or so to cut them out I could have just bought some shackles.

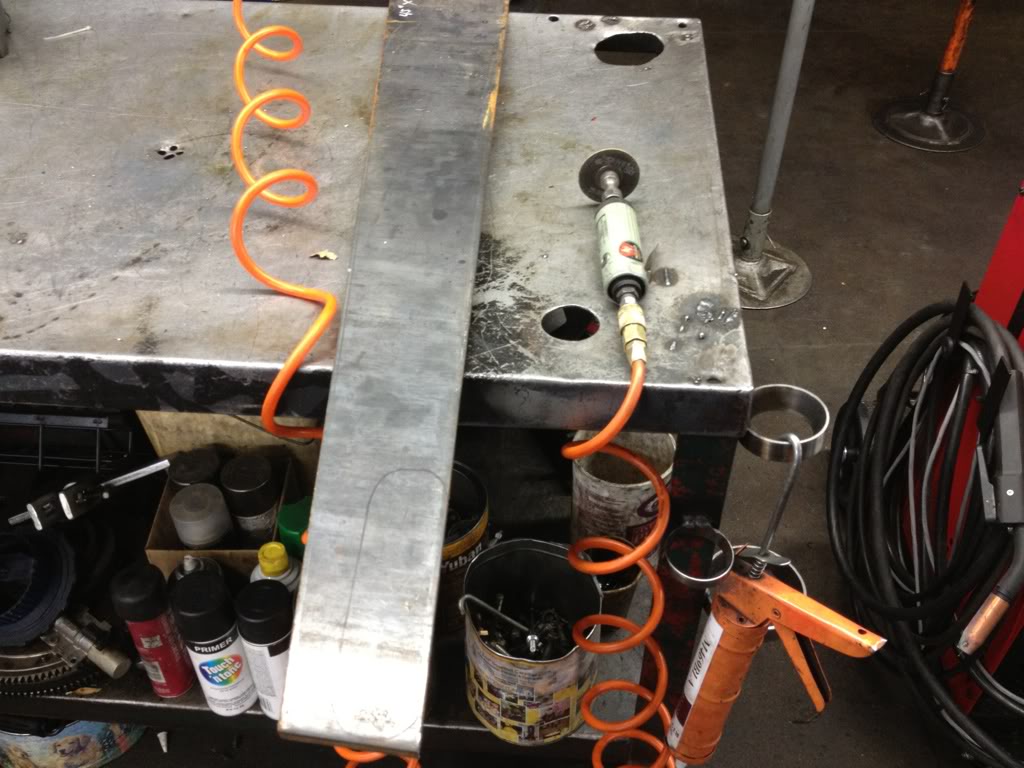

But I did hook up with a guy who let me use his plasma! It was my first time with a plasma , the first cut or 2 was a lil ugly but in the end all 8 shackles were cut out in about 30 min.

But I did hook up with a guy who let me use his plasma! It was my first time with a plasma , the first cut or 2 was a lil ugly but in the end all 8 shackles were cut out in about 30 min.

#14

Registered User

Thread Starter

Meh, not factory but will work just fine. These were the rear shackles 6in eye to eye x 2in wide 3/8 thick. I'll post pics tomorrow of the 5" eye to eye for the front.

Last edited by 775Toy; 01-05-2012 at 06:41 PM.

#15

Registered User

grinder and 4 1/2 inch cut off wheels are your best bet for sure. I like Walter zip wheels personally. You can make some darn good cuts with them if you just draw it out, follow your lines and let the grinder do the work.

carefully cut along your line and make a groove to follow. Then just using the weight of the grinder do the cutting and you'll be good.

carefully cut along your line and make a groove to follow. Then just using the weight of the grinder do the cutting and you'll be good.

#16

Registered User

haha, never mind you ended up with a plasma. Anyways, next time try using a piece of 1/8th (using a factory edge and clamp it down) for a guide instead of a tube, you can get very smooth cuts that way.

#18

Registered User

Thread Starter

Ya for sure man the Tube was wack. I used a price of angle iron stood up on the last couple cuts. It worked way better than the tube as a guide. It was my first experience with a plasma , it was pretty rad but not as easy as it looks with thick steel. I would had defiantly gone 4.5" cut off wheel if I hadn't found a plasma to borrow.

#19

Registered User

Thread Starter

Thanks for the replies.

Thread

Thread Starter

Forum

Replies

Last Post

Longbed 90

86-95 Trucks & 4Runners

22

03-11-2019 12:38 PM

runnermedic

95.5-2004 Tacomas & 96-2002 4Runners

13

09-21-2015 05:20 PM