Last edit by: IB Advertising

See related guides and technical advice from our community experts:

- Toyota Tundra How to Replace Timing Belt and Water Pump<br>Step by step instructions for do-it-yourself repairs.

Tundra 4.7 (2uz) Timing Belt & Water Pump Replacement

#1

Registered User

Thread Starter

Tundra 4.7 (2uz) Timing Belt & Water Pump Replacement

Well, my 2000 Tundra has 109,000 miles on it,and since the timing belt interval is 90,000 miles, I decided I had better get it replaced. The 2uz is an interference engine, so a timing belt failure means bent valves and a very expensive repair bill. Since (as is the case with many Yota engines) the water pump is t-belt driven, I wanted to go ahead and change it out too.

I purchased a timing belt kit on e-bay from a seller named volkstoy. I had heard good things about the kits on Tundrasolutions, so I bought one. It included the t-belt, water pump, gaskets, t-belt tensioner pulley, t-belt idler pulley, cam seals and crank seal(I did not replace the cam or crank seals because mine were not leaking), serpentine belt, along with a gasket and o-ring for the water inlet assembly, which is mounted atop the water pump. The belts are made by Bando, and the w/p and bearings are GMB. The set costs $230 and the shipping is free. Here is the set:

I have a Chilton's manual that I used for reference, even though I have done many t-belts on various other makes and models. A Toyota FSM would undoudtable be better, but the Chilton's was actually pretty complete. Be sure to have a manual before you start this job because it is pretty involved. Basic hand tools are needed for this job. Most of the fasteners are of the 10mm, 12mm, and 14mm variety. I used my 1/2 impact to loosen the crank bolt, and I needed to use my harmonic balancer/steering wheel puller to get the crank pulley off.

First, I disconnected the negative battery cable, removed the skid plate and drained the radiator. Then I removed the air intake tube, fan shroud, and radiator, then the fan itself. After that stuff is removed, you can start to see what you are up against to get the timing components removed:

Now it is time to start removing the timing belt covers and all the other stuff that is in the way. First, I removed the right side timing cover, the smaller timing cover next to it, and the serp belt idler pulley (all references to right and left are from the perspective of sitting in the driver's seat, and are completely opposite of how it looks when looking at the engine from standing in front of it. This is how my Chilton's manual is, so I have kept with that same orientation to avoid confusion for someone referencing this post and their manual simultaneously).

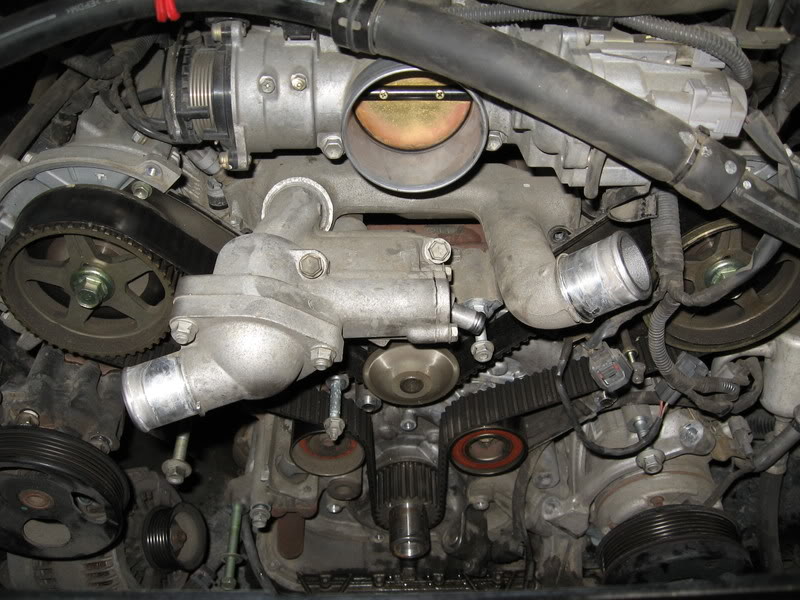

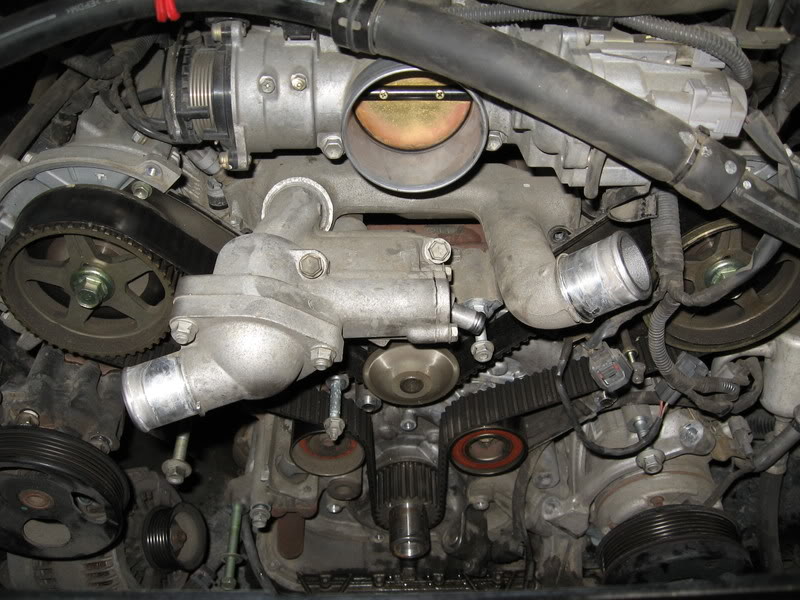

Then it was time to work on the left side timing cover. As shown in the following picture, there is more stuff to remove in order to get this side off. There is a coolant tube that goes from the water pump and tees off to the throttle body and down to the oil cooler (have a pan ready because even though the radiator is empty, there is a bunch of coolant waiting to spew forth once the lower end of that tube is removed). There is also a wire lead (for the cam sensor)coming through a grommeted hole in the cover on this side that needs to be dealt with. Here is how it looks:

And with the coolant pipe and that cover removed:

Next I removed the fan bracket. The a/c compressor mount ties into this bracket, so I found it necessary to remove two bolts holding the a/c compressor to the fan bracket.

On the other side, I removed the serp belt tensioning pulley assembly. The alternator must be removed in order to get it off. In order to get the alternator off, one needs to remove the power steering pump. The p/s pump is removed by pulling two bolts and a nut from the front of the pump; there are holes in the pulley, so you can even acces them with a socket. Pull the p/s pump off (lay it to the front with the hoses till attached), then you can remove the alternator and lay it down below. There is no need to remove the wires, just move it enough so that it is out of the way. Then I put the p/s pump back in place and loosly started the bolts and nut. It was not in the way of anything I needed to do after removing the alt. After that is done the tensioner assy comes right off.

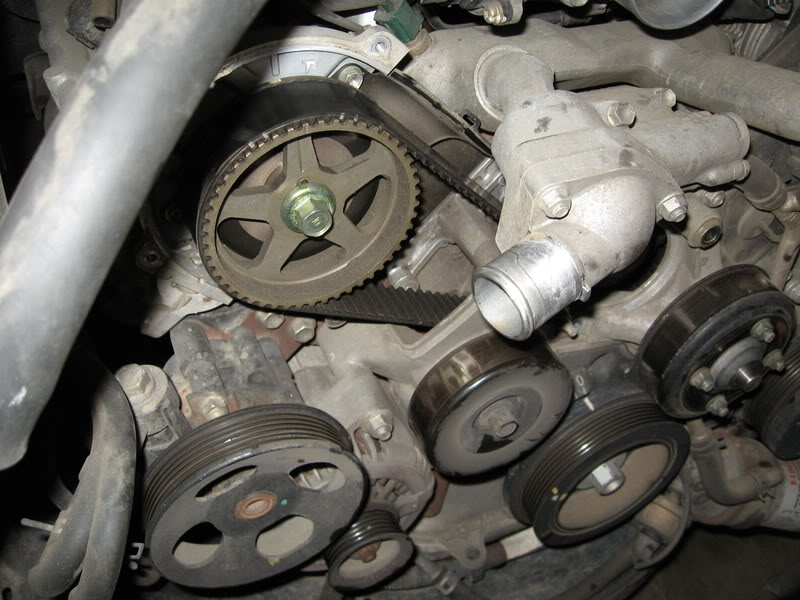

At this point I rotated the engine around to TDC on cyl#1. I insured that I was on the compression stroke by looking at the now exposed timing marks on the camshaft sprockets. On each side of the backing plate behind the cam sprocket there is a vertical mark and a "T". The vertical mark is TDC and the "T" is a mark you will use while installing the belt. You can see the marks on the pictures above.

When that was done, I used my impact with a 22mm socket to remove the crank pulley bolt. At this point I should mention that this can be the single most frustrating part of this job if you don't have the right tools. The bolt is pretty tight, comparatively speaking. An impact will usually just zip it right off, but it is much harder to do with a breaker bar because the engine wants to turn instead of the bolt loosening. Usually you have to hold the pulley with a special pulley holding tool, or a chain wrench wrapped around the pulley. It can be a RPITA, so be prepared to mess with it a bit if you have never removed a crankshaft bolt. There is another method which uses a breaker bar up against the frame and bumping the starter. I don't do it this way because it has the potential to be dangerous and damaging. IF YOU DO DECIDE TO DO IT THIS WAY, DISABLE THE IGNITION SYSTEM SO THE ENGINE WILL NOT START WHILE "BUMPING THE STARTER".

With the bolt out, I used my harmonic balancer pulley to get the pulley off (you can borrow or rent a puller from many auto parts stores):

Now it was time to remove the small cover around the crankshaft, and you can see that the belt and water pump are next:

First the t-belt. I removed the t-belt tensioner by removing the two bolts that hold it on. It is seperate from the tensioner pulley and with it removed there is no tension on the pulley and belt. I didn't get any pics of that process, but the belt comes right off after that. The I removed the t-belt tensioner pulley and the idler pully.

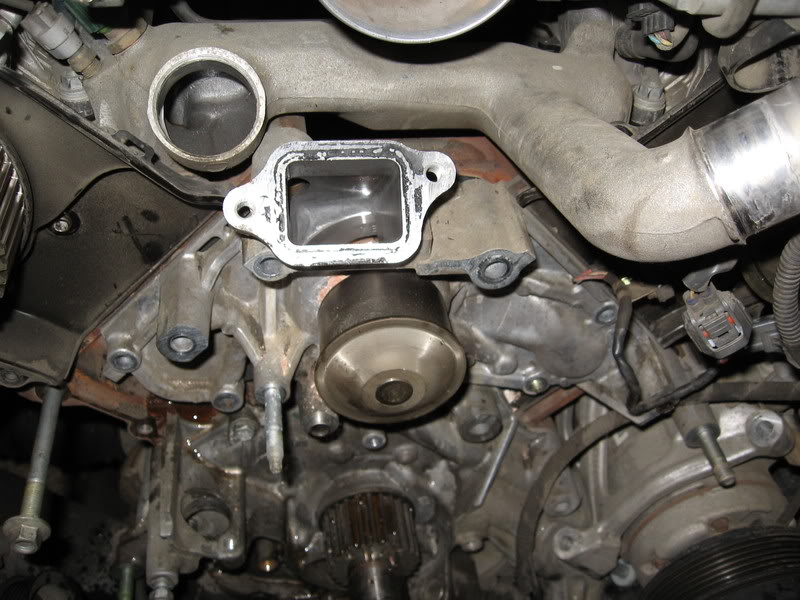

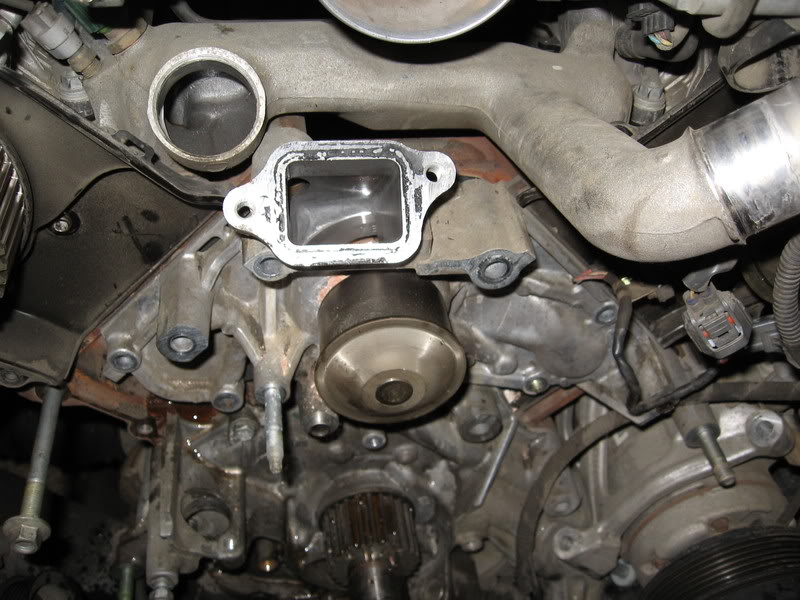

Now I still had the water inlet housing attached to the w/p as seen in the above pictures. It comes off by removing the two bolts angling downward from the top. It has a silicone seal and an o-ring holding it together and mine was tough to get off. I finally had to nudge it with a rubber mallet to get it freed up enough to twist it back and forthe enough to wiggle it off. The o-ring bore is a tight fit and makes it feel like you forgot to remove a bolt or something. When it is off it looks like this:

Now you can remove the w/p. Keep track of where all of the bolts and studs go. You will notice that you removed one of the bolts earlier when you removed the small cover. The rest of them are small bolts or studs which have the nuts already removed during prior disassebly of the tensioner pulley and the fan bracket. Have your drain pan positioned under the w/p because it is a gusher. Here is what it looks like when it is off:

When I got my belt and pulley off, I noticed a couple of things. First, the belt looked like it was still in fairly decent shape, with no obvious areas of concern. I know some people have tempted fate and ran them for many miles over what I did. My w/p was a different story. I could see some pink concretions under the pulley and at the weep hole that were casued by coolant leakage. Slight leakage, but leakage non-the-less. This crumby picture shows what I am talking about, sorry it it so blurry:

I imagine that if I had neglected to do this preventative maintenance, the water pump would have sprung a serious leak sometime in the near future. I'm sure it would have failed and required teardown before the timing belt broke anyway, if I had not performed this repair. If I had decided to just do the t-belt and not mess with the w/p, I would have been tearing it all apart again to replace the w/p. obviously, this is why it is best to get it all in one shot, and the extra expense is worth it. I got lazy and elected not to replace the crankshaft and camshaft seals. They were completely leak free, so I decided to let sleeping dogs lie. I hope it doesn't come back to bite me!

Next I cleaned the gasket surface and installed the w/p and gasket with black RTV. Then I installed the new idler and tensioner pullies. Now for the belt.

I mentioned earlier that I have replaced t-belts on a number of different makes and models. Many of them have little tricks and techniques to get everything all set up correctly, and this one is no different. I recommend reading and re-reading your manual before you start setting up the cam timing because it is a critical step.

It is easiest to do this if you have an extra arm extending from the center of your chest, but if not, a frind can help you hold the t-belt while you get it all lined up and indexed. The process on this engine goes as follows:

The new timing belt should have marks on it that correspond to the marks on the cam sprockets and the crank sprocket. The references are from sitting in the drivers seat, so they are reversed from the way you are looking at it and that can get confusing. Make sure that the crank is at TDC by referencing a groove on the upper side of the crank sprocket and a raised dimple on the oil pump housing( I regretfully didn't get a good pic of that mark, but you will see it and understand immediately). Start by positioning the left cam sprocket (on your right side) at the "T" position and then install the belt so the line on the belt matches up with the line on the sprocket. Have a helper hold the belt on the cam sprocket so it does not move, then route the belt onto the crank sprocket so that the line on the belt is in line with the dot on the lower side (this is not the crank TDC reference I mentioned above. It is a seperate mark which can be seen on the lower side front of the crank sprocket). Only those two sprockets are engaged with the belt at this point. Now you need to use a 17mm wrench on the cam sprocket and gently rotate the mark on the sprocket so it lines up with the straight line on the backing plate. That will take up all the slack in the belt between the cam sprocket and the crank sprocket. You can now position the right side (again, it is on your left) cam sprocket on the "T" mark and finish routing the t-belt onto it and around the tensioner and idler. Make sure the line on the belt is lined up with the mark on the sprocket, then gently rotate the cam sprocket so that the mark on it lines up with the straight line on the backing plate. That will put tension on the belt between the two cam sprockets and conveniently put all the slack on the side of the belt adjacent to the tensioner.

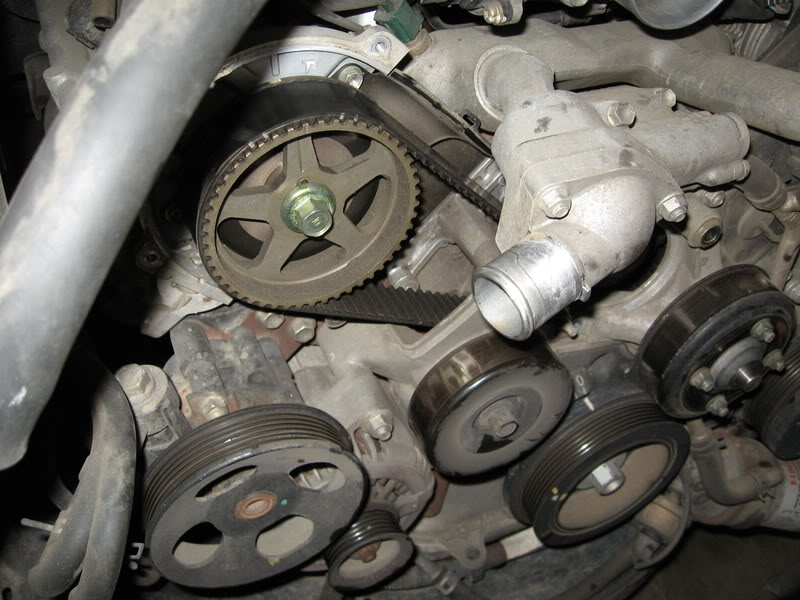

A few words about the tensioner. When I removed mine, I tested it by trying to push the now extended rod back into the body by holding it against my bench vise and leaning my body weight against it. It didn't budge and therefore appeared to be satisfactory. Then I had to get it ready to reinstall. I forgot to get pics of this process as well, but it is in the manual. I placed the tensioner in my vice so that when I turned the handle it would compress the shaft into the body. There is a hole in the shaft that lines up with a hole in the tensioner body when compressed. I inserted a small nail in the hole to hold the shaft in the body until assembly. I then bolted the tensioner onto the bracket and pulled the nail out which allows the tensioner to apply tension to the belt. It looked like this when I was all done. The tensioner is barely seen on the bottom left of the photo. The shaft pushes straight up on the tensioner pulley assenbly.

After I made sure the marks were all lined up properly, I temporarily reinstalled the crankshaft bolt and used a 22mm socket on a ratchet to rotate the engine two complete revolutions. This should bring everything back into place for a quick double check of the cam timing. The notch and bump on the crank pulley are in place and the mark on the cam sprockets are lined up with the straight lines on the backing plates. The lines on the belt are no longer in place, but that is normal and not a point of concern. They are there as a reference for installation only, and as long as the marks on the sprockets themselves line up all is well.

Now it is just a matter of doing all of the teardown steps in reverse order until it is all back together. I lubed the o-ring on the water inlet housing with antifreeze in order to get it to go back together smoothly, and every thing buttoned back up nicely. I filled it with Toyota red antifreeze, changed the oil just because and started it up. As with other Yota pickups, the Tundra is kind of tricky to get the air pocket out of the heater core (burped). I had the Tundra running (heater on full blast)with the radiator cap off on my inclined driveway, but ended up jacking the front of the truck up another foot in order to get it to burp. You can tell when it burps because it will start spewing air and hot coolant out of the radiator filler and the air will finally star to feel warm coming out of the vents. When all of the air is burped out, you can finish filling the radiator and you are done.

The finished product-ready for many more miles of trouble free service:

I purchased a timing belt kit on e-bay from a seller named volkstoy. I had heard good things about the kits on Tundrasolutions, so I bought one. It included the t-belt, water pump, gaskets, t-belt tensioner pulley, t-belt idler pulley, cam seals and crank seal(I did not replace the cam or crank seals because mine were not leaking), serpentine belt, along with a gasket and o-ring for the water inlet assembly, which is mounted atop the water pump. The belts are made by Bando, and the w/p and bearings are GMB. The set costs $230 and the shipping is free. Here is the set:

I have a Chilton's manual that I used for reference, even though I have done many t-belts on various other makes and models. A Toyota FSM would undoudtable be better, but the Chilton's was actually pretty complete. Be sure to have a manual before you start this job because it is pretty involved. Basic hand tools are needed for this job. Most of the fasteners are of the 10mm, 12mm, and 14mm variety. I used my 1/2 impact to loosen the crank bolt, and I needed to use my harmonic balancer/steering wheel puller to get the crank pulley off.

First, I disconnected the negative battery cable, removed the skid plate and drained the radiator. Then I removed the air intake tube, fan shroud, and radiator, then the fan itself. After that stuff is removed, you can start to see what you are up against to get the timing components removed:

Now it is time to start removing the timing belt covers and all the other stuff that is in the way. First, I removed the right side timing cover, the smaller timing cover next to it, and the serp belt idler pulley (all references to right and left are from the perspective of sitting in the driver's seat, and are completely opposite of how it looks when looking at the engine from standing in front of it. This is how my Chilton's manual is, so I have kept with that same orientation to avoid confusion for someone referencing this post and their manual simultaneously).

Then it was time to work on the left side timing cover. As shown in the following picture, there is more stuff to remove in order to get this side off. There is a coolant tube that goes from the water pump and tees off to the throttle body and down to the oil cooler (have a pan ready because even though the radiator is empty, there is a bunch of coolant waiting to spew forth once the lower end of that tube is removed). There is also a wire lead (for the cam sensor)coming through a grommeted hole in the cover on this side that needs to be dealt with. Here is how it looks:

And with the coolant pipe and that cover removed:

Next I removed the fan bracket. The a/c compressor mount ties into this bracket, so I found it necessary to remove two bolts holding the a/c compressor to the fan bracket.

On the other side, I removed the serp belt tensioning pulley assembly. The alternator must be removed in order to get it off. In order to get the alternator off, one needs to remove the power steering pump. The p/s pump is removed by pulling two bolts and a nut from the front of the pump; there are holes in the pulley, so you can even acces them with a socket. Pull the p/s pump off (lay it to the front with the hoses till attached), then you can remove the alternator and lay it down below. There is no need to remove the wires, just move it enough so that it is out of the way. Then I put the p/s pump back in place and loosly started the bolts and nut. It was not in the way of anything I needed to do after removing the alt. After that is done the tensioner assy comes right off.

At this point I rotated the engine around to TDC on cyl#1. I insured that I was on the compression stroke by looking at the now exposed timing marks on the camshaft sprockets. On each side of the backing plate behind the cam sprocket there is a vertical mark and a "T". The vertical mark is TDC and the "T" is a mark you will use while installing the belt. You can see the marks on the pictures above.

When that was done, I used my impact with a 22mm socket to remove the crank pulley bolt. At this point I should mention that this can be the single most frustrating part of this job if you don't have the right tools. The bolt is pretty tight, comparatively speaking. An impact will usually just zip it right off, but it is much harder to do with a breaker bar because the engine wants to turn instead of the bolt loosening. Usually you have to hold the pulley with a special pulley holding tool, or a chain wrench wrapped around the pulley. It can be a RPITA, so be prepared to mess with it a bit if you have never removed a crankshaft bolt. There is another method which uses a breaker bar up against the frame and bumping the starter. I don't do it this way because it has the potential to be dangerous and damaging. IF YOU DO DECIDE TO DO IT THIS WAY, DISABLE THE IGNITION SYSTEM SO THE ENGINE WILL NOT START WHILE "BUMPING THE STARTER".

With the bolt out, I used my harmonic balancer pulley to get the pulley off (you can borrow or rent a puller from many auto parts stores):

Now it was time to remove the small cover around the crankshaft, and you can see that the belt and water pump are next:

First the t-belt. I removed the t-belt tensioner by removing the two bolts that hold it on. It is seperate from the tensioner pulley and with it removed there is no tension on the pulley and belt. I didn't get any pics of that process, but the belt comes right off after that. The I removed the t-belt tensioner pulley and the idler pully.

Now I still had the water inlet housing attached to the w/p as seen in the above pictures. It comes off by removing the two bolts angling downward from the top. It has a silicone seal and an o-ring holding it together and mine was tough to get off. I finally had to nudge it with a rubber mallet to get it freed up enough to twist it back and forthe enough to wiggle it off. The o-ring bore is a tight fit and makes it feel like you forgot to remove a bolt or something. When it is off it looks like this:

Now you can remove the w/p. Keep track of where all of the bolts and studs go. You will notice that you removed one of the bolts earlier when you removed the small cover. The rest of them are small bolts or studs which have the nuts already removed during prior disassebly of the tensioner pulley and the fan bracket. Have your drain pan positioned under the w/p because it is a gusher. Here is what it looks like when it is off:

When I got my belt and pulley off, I noticed a couple of things. First, the belt looked like it was still in fairly decent shape, with no obvious areas of concern. I know some people have tempted fate and ran them for many miles over what I did. My w/p was a different story. I could see some pink concretions under the pulley and at the weep hole that were casued by coolant leakage. Slight leakage, but leakage non-the-less. This crumby picture shows what I am talking about, sorry it it so blurry:

I imagine that if I had neglected to do this preventative maintenance, the water pump would have sprung a serious leak sometime in the near future. I'm sure it would have failed and required teardown before the timing belt broke anyway, if I had not performed this repair. If I had decided to just do the t-belt and not mess with the w/p, I would have been tearing it all apart again to replace the w/p. obviously, this is why it is best to get it all in one shot, and the extra expense is worth it. I got lazy and elected not to replace the crankshaft and camshaft seals. They were completely leak free, so I decided to let sleeping dogs lie. I hope it doesn't come back to bite me!

Next I cleaned the gasket surface and installed the w/p and gasket with black RTV. Then I installed the new idler and tensioner pullies. Now for the belt.

I mentioned earlier that I have replaced t-belts on a number of different makes and models. Many of them have little tricks and techniques to get everything all set up correctly, and this one is no different. I recommend reading and re-reading your manual before you start setting up the cam timing because it is a critical step.

It is easiest to do this if you have an extra arm extending from the center of your chest, but if not, a frind can help you hold the t-belt while you get it all lined up and indexed. The process on this engine goes as follows:

The new timing belt should have marks on it that correspond to the marks on the cam sprockets and the crank sprocket. The references are from sitting in the drivers seat, so they are reversed from the way you are looking at it and that can get confusing. Make sure that the crank is at TDC by referencing a groove on the upper side of the crank sprocket and a raised dimple on the oil pump housing( I regretfully didn't get a good pic of that mark, but you will see it and understand immediately). Start by positioning the left cam sprocket (on your right side) at the "T" position and then install the belt so the line on the belt matches up with the line on the sprocket. Have a helper hold the belt on the cam sprocket so it does not move, then route the belt onto the crank sprocket so that the line on the belt is in line with the dot on the lower side (this is not the crank TDC reference I mentioned above. It is a seperate mark which can be seen on the lower side front of the crank sprocket). Only those two sprockets are engaged with the belt at this point. Now you need to use a 17mm wrench on the cam sprocket and gently rotate the mark on the sprocket so it lines up with the straight line on the backing plate. That will take up all the slack in the belt between the cam sprocket and the crank sprocket. You can now position the right side (again, it is on your left) cam sprocket on the "T" mark and finish routing the t-belt onto it and around the tensioner and idler. Make sure the line on the belt is lined up with the mark on the sprocket, then gently rotate the cam sprocket so that the mark on it lines up with the straight line on the backing plate. That will put tension on the belt between the two cam sprockets and conveniently put all the slack on the side of the belt adjacent to the tensioner.

A few words about the tensioner. When I removed mine, I tested it by trying to push the now extended rod back into the body by holding it against my bench vise and leaning my body weight against it. It didn't budge and therefore appeared to be satisfactory. Then I had to get it ready to reinstall. I forgot to get pics of this process as well, but it is in the manual. I placed the tensioner in my vice so that when I turned the handle it would compress the shaft into the body. There is a hole in the shaft that lines up with a hole in the tensioner body when compressed. I inserted a small nail in the hole to hold the shaft in the body until assembly. I then bolted the tensioner onto the bracket and pulled the nail out which allows the tensioner to apply tension to the belt. It looked like this when I was all done. The tensioner is barely seen on the bottom left of the photo. The shaft pushes straight up on the tensioner pulley assenbly.

After I made sure the marks were all lined up properly, I temporarily reinstalled the crankshaft bolt and used a 22mm socket on a ratchet to rotate the engine two complete revolutions. This should bring everything back into place for a quick double check of the cam timing. The notch and bump on the crank pulley are in place and the mark on the cam sprockets are lined up with the straight lines on the backing plates. The lines on the belt are no longer in place, but that is normal and not a point of concern. They are there as a reference for installation only, and as long as the marks on the sprockets themselves line up all is well.

Now it is just a matter of doing all of the teardown steps in reverse order until it is all back together. I lubed the o-ring on the water inlet housing with antifreeze in order to get it to go back together smoothly, and every thing buttoned back up nicely. I filled it with Toyota red antifreeze, changed the oil just because and started it up. As with other Yota pickups, the Tundra is kind of tricky to get the air pocket out of the heater core (burped). I had the Tundra running (heater on full blast)with the radiator cap off on my inclined driveway, but ended up jacking the front of the truck up another foot in order to get it to burp. You can tell when it burps because it will start spewing air and hot coolant out of the radiator filler and the air will finally star to feel warm coming out of the vents. When all of the air is burped out, you can finish filling the radiator and you are done.

The finished product-ready for many more miles of trouble free service:

Last edited by zlathim; 12-22-2009 at 05:52 AM. Reason: details man, details

#6

Registered User

Thread Starter

Thanks for the kind words.

Trending Topics

#8

Contributing Member

Wow I never would have thought to look for this kind of write up here , glad you pulled it up and I saw it .

I dont have a tundra but do have a 1uz and its good just to get an Idea of some of these parts removed.

Another thing to bad the 2uz and 3uz are interferance engines , and Im lucky the early 1uz is not .

Thanks Zlathim for the write up.

I dont have a tundra but do have a 1uz and its good just to get an Idea of some of these parts removed.

Another thing to bad the 2uz and 3uz are interferance engines , and Im lucky the early 1uz is not .

Thanks Zlathim for the write up.

#9

Registered User

Thread Starter

Wow I never would have thought to look for this kind of write up here , glad you pulled it up and I saw it .

I dont have a tundra but do have a 1uz and its good just to get an Idea of some of these parts removed.

Another thing to bad the 2uz and 3uz are interferance engines , and Im lucky the early 1uz is not .

Thanks Zlathim for the write up.

I dont have a tundra but do have a 1uz and its good just to get an Idea of some of these parts removed.

Another thing to bad the 2uz and 3uz are interferance engines , and Im lucky the early 1uz is not .

Thanks Zlathim for the write up.

Last edited by zlathim; 09-09-2009 at 12:55 PM.

#11

Registered User

Thread Starter

I did a short write up on removing the starter here:

https://www.yotatech.com/forums/f28/...tarter-131576/

I didn't detail replacing the solenoid contacts, but it is very easy after you get the starter out. Just remove the rear cover from the solenoid assembly and access the contacts. When you have new contacts in your hand, it is easy to see how they come out and go back in. Good luck.

#12

I got the contacts of the starter out and am waiting for dealer to get parts. T/B being changed along with w/p. there was a small amount of weepage. the replacement gasket is paper and looks pretty cheap compaired to the one that came off ( 3 piece metal). this truck is one of the first 1000 made at the princeton plant and other then rotors I haven't had a problem. thanks for the help. any idea is the remanu. starters are as good or last as long as this repair? ($184) vs ($16)

#13

Registered User

Join Date: Aug 2002

Location: South Texas

Posts: 25

Likes: 0

Received 0 Likes

on

0 Posts

Good Info

Great write up. Thank you for posting; my '01 just hit 100k and is due any day now. How many miles were on your belt? Do not recall seeing the mileage. thanks.

#14

Registered User

Thread Starter

I got the contacts of the starter out and am waiting for dealer to get parts. T/B being changed along with w/p. there was a small amount of weepage. the replacement gasket is paper and looks pretty cheap compaired to the one that came off ( 3 piece metal). this truck is one of the first 1000 made at the princeton plant and other then rotors I haven't had a problem. thanks for the help. any idea is the remanu. starters are as good or last as long as this repair? ($184) vs ($16)

I used the paper gasket that came in the set. It has been fine so far, but if I would have had the time to get a new steel and rubber gasket from the dealer I would have. My circumstance wouldn't allow me the trip to the dealer. I used silicone sealent on both sides of the paper gasket and it hasn't leaked yet.

Mine had 109,000 miles and looked like the belt could go another 20,000 easily. My water pump had been seeping though, and I'm sure it would have started leaking sooner rather than later.

#15

Gettin there

Found a trick for getting the balancer bolt off. remove the inspection plate on bottom of fly wheel and u will find a hole in the wheel large enough to insert a tire lug wrench (big end)to stop the fly wheel so you can turn the bolt off the balancer. I did it with no help. I also found the belt to be in very good shape along with the water pump and serpentine belt. the starter contacts will be replaced but I am waiting on a new plunger in the starter soleniod because it also looks a little thin. I really don't want to do this again, Did I mention the crappy are biting and its really hard to catch em with a ratchet in your hand. LOL

#16

Registered User

Join Date: May 2009

Location: prince rupert

Posts: 19

Likes: 0

Received 0 Likes

on

0 Posts

bump for a very well illustrated

wow.....brings back memories when I change the timing belt on my 2000 toyota 4runner 3.4 but i used toyota original parts and changed all the belts...

again hats off to you and others can surely use this

wow.....brings back memories when I change the timing belt on my 2000 toyota 4runner 3.4 but i used toyota original parts and changed all the belts...

again hats off to you and others can surely use this