1996 t100 4x4 work in progress

#81

Registered User

If you don't mind me asking Z, which brand BJ were you running? I replaced mine with Moog about 20k ago, but ever since, I've had this bad feeling I haven't been able to shake. Since I have to replace a upper control arm, I was planning on replacing the ball joints again just to try and help alleviate my anxiety.

#82

Registered User

Thread Starter

If you don't mind me asking Z, which brand BJ were you running? I replaced mine with Moog about 20k ago, but ever since, I've had this bad feeling I haven't been able to shake. Since I have to replace a upper control arm, I was planning on replacing the ball joints again just to try and help alleviate my anxiety.

Apparently the ball joints to get are marked with 555 on them meaning they are of high quality and japanese, Here is a little thread that mentions it. https://www.yotatech.com/forums/f2/g...joints-268729/

You might also want to take a look at this website speedwaymotors.com Look at the Howe precision BJs. These are some upgrades I am considering for the MT. I was also considering making UCA Extension Brackets with Howe BJs with screw on weld in cups. The Howe design may be a good alternative to uniball. Compared to OME Howe may be stronger? Another advantage is the Howe is serviceable and will allow a 32 degree angle range compared to 23 degree angle of the stock Toyota units.

With the Uniball there is bolt going straight through the whole thing so even with repetitive tugging down on that bolt nothing can fail.

Its a smittybuilt

Last edited by Zpd426; 01-05-2014 at 09:50 PM.

#83

Registered User

Nice to see the stages of build up after seeing it in person. I kept forgetting to ask you what that contraption is on your rear diff...sweet truck man!

Not sure what came of the fab shop that made these, but the guy running them was certainly happy. He hasn't been on yotatech in over a year now, and it seems rough road fabrication's website is down, but I figured this might at least give you some hope it can be done.

https://www.yotatech.com/forums/f116...-setup-245909/

Not sure what came of the fab shop that made these, but the guy running them was certainly happy. He hasn't been on yotatech in over a year now, and it seems rough road fabrication's website is down, but I figured this might at least give you some hope it can be done.

https://www.yotatech.com/forums/f116...-setup-245909/

#84

Registered User

Thread Starter

Thanks, Ive heard that someone used to make a bolt in Uniball... Looks like they are gone and im on my own though.

Interesting update!! I though I had some crap chinese ball joints... BUT 555!

Interesting update!! I though I had some crap chinese ball joints... BUT 555!

Last edited by Zpd426; 01-06-2014 at 04:31 PM.

#86

Registered User

Thread Starter

Oh I almost forgot. John the thing on my Diff is a skid plate/driveshaft disconnect for when we used to tow the t100 behind the motorhome.

And if you mean the other thing, its just a axle truss for reinforcement.

Anyways it looks like the Joint had been maxing out and I think the metal was defective as well.

Maybe I need a different upper ball joint? Does it matter what year I get? Maybe I need a 4Runner or Truck joint? Maybe I Just had my Suspension set too high? Oh well... Uniballs coming anyway.. And with a 4" lift will solve both issues.

And if you mean the other thing, its just a axle truss for reinforcement.

Anyways it looks like the Joint had been maxing out and I think the metal was defective as well.

Maybe I need a different upper ball joint? Does it matter what year I get? Maybe I need a 4Runner or Truck joint? Maybe I Just had my Suspension set too high? Oh well... Uniballs coming anyway.. And with a 4" lift will solve both issues.

Last edited by Zpd426; 01-06-2014 at 04:38 PM.

#87

Registered User

Thread Starter

The only pic I took. Steep hill. I slid pretty far down. Didnt get a pick of the second break when my A arm made a nice gouge in the ground.

Last edited by Zpd426; 01-06-2014 at 04:49 PM.

#88

Registered User

Was nice reading your build thread. Totally love what you did with the truck. actually the first t100 that i like! great job. Sorry to hear thats the only picture you have of your rig. I'll have to look through mine and chefs to see if we have some of yours. I know i have osme of you guys doing the repair as well but not in action. SUBSCRIBED! Nice meeting ya. And hopefully you wont have this problem next time.

#89

Registered User

Zack,

Thanks for posting pictures of your Upper and Lower Ball Joints. I don't believe there are different upper ball joints pertaining to year or model. Maybe someone can cross reference part number to verify. I vaguely remember someone did this on Pirate? I did want to point out a few observations:

Photos 1-3: Three Five 555 Lower BJ "cup" (4) bolt holes.

Photo 4-5: Upper BJ "ball stud", yes upper!

Photo 6: Lower BJ "ball stud" along with Upper BJ "cup" (4) stud flange, studs removed.

I believe you miss matched the ball and socket in photo #6. It is important to get the relation correct when trying to identify the failure. When matched it up correctly, and by following the sequence of events, we might figure some things out.

Your T-100 beast was in the process of climbing a hill in 4WD and the upper BJ popped out of the socket? This could happened because the UCA hammers down on the droop stop and the hanging weight of the wheel, spindle, LCA, etc, is pulling down on the upper BJ as the droop stops bottom out. To compound matters you have a coil over conversion that causes an additional force in form of a spring load on the LCA (a 600 lb spring). I think those two forces are hammering down on the upper BJ so that one last repetative hit just popped it out.

With a dislocated upper ball joint you backed the vehicle back down the hill where the Lower BJ broke. You can see the cup is split to the side, indicating a side load to the cup. As the wheel was flopping around and being drug its understandable the Lower BJ would fail. This also could bend the ball stud as pictured. Like a tow strap looped around a tow ball on a trailer hitch.

I think one could prevent the upper Ball Joint from being pulled apart in he first place by adding a limit strap that connects the LCA to an anchor point on the frame. This moves the spring load directly to the strap. It also moves the hanging weight off the upper ball joint. Lastly it flips the hanging weight to the Lower BJ- as a compression force. The Lower BJ is designed to handle compressive loads.

I think the factory droop stop design is fine with torsion bars- as the spring load is terminated directly on the droop stops. With a coil over conversion, the additional spring load is added to the upper BJ hanging loads. These combined tension forces over time or with a hard enough tug pull the ball out of the socket.

Not saying I am correctly diagnosing this failure but just trying to think it through. Could just be a fluke event? If you patched it all up its possible it would never happen again!

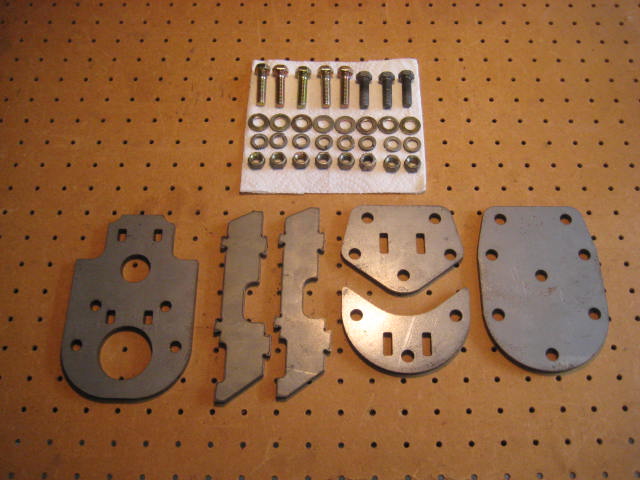

I have observed many ball joints in my searching for UCA and LCA cores in the salvage yards. I see lots of front end acccidents involving front suspension failure and damage. Here are a few samples. The BJ on the bottom right of the group had the ball stud ripped out of the cup like yours. The opening should be a slot not a circle.

Thanks for posting pictures of your Upper and Lower Ball Joints. I don't believe there are different upper ball joints pertaining to year or model. Maybe someone can cross reference part number to verify. I vaguely remember someone did this on Pirate? I did want to point out a few observations:

Photos 1-3: Three Five 555 Lower BJ "cup" (4) bolt holes.

Photo 4-5: Upper BJ "ball stud", yes upper!

Photo 6: Lower BJ "ball stud" along with Upper BJ "cup" (4) stud flange, studs removed.

I believe you miss matched the ball and socket in photo #6. It is important to get the relation correct when trying to identify the failure. When matched it up correctly, and by following the sequence of events, we might figure some things out.

Your T-100 beast was in the process of climbing a hill in 4WD and the upper BJ popped out of the socket? This could happened because the UCA hammers down on the droop stop and the hanging weight of the wheel, spindle, LCA, etc, is pulling down on the upper BJ as the droop stops bottom out. To compound matters you have a coil over conversion that causes an additional force in form of a spring load on the LCA (a 600 lb spring). I think those two forces are hammering down on the upper BJ so that one last repetative hit just popped it out.

With a dislocated upper ball joint you backed the vehicle back down the hill where the Lower BJ broke. You can see the cup is split to the side, indicating a side load to the cup. As the wheel was flopping around and being drug its understandable the Lower BJ would fail. This also could bend the ball stud as pictured. Like a tow strap looped around a tow ball on a trailer hitch.

I think one could prevent the upper Ball Joint from being pulled apart in he first place by adding a limit strap that connects the LCA to an anchor point on the frame. This moves the spring load directly to the strap. It also moves the hanging weight off the upper ball joint. Lastly it flips the hanging weight to the Lower BJ- as a compression force. The Lower BJ is designed to handle compressive loads.

I think the factory droop stop design is fine with torsion bars- as the spring load is terminated directly on the droop stops. With a coil over conversion, the additional spring load is added to the upper BJ hanging loads. These combined tension forces over time or with a hard enough tug pull the ball out of the socket.

Not saying I am correctly diagnosing this failure but just trying to think it through. Could just be a fluke event? If you patched it all up its possible it would never happen again!

I have observed many ball joints in my searching for UCA and LCA cores in the salvage yards. I see lots of front end acccidents involving front suspension failure and damage. Here are a few samples. The BJ on the bottom right of the group had the ball stud ripped out of the cup like yours. The opening should be a slot not a circle.

Last edited by BlazeN8; 01-06-2014 at 07:51 PM.

#90

Registered User

Thread Starter

Nate.... After closer inspection you are right!

Ive been doing this all during study breaks....

Haha I just drew up a print for the Lower ball joint.... At least the upper one is easier to do!

So the joint that failed was a Chinese joint after all. And it is incorrect that it has a round slot?

I think you are right on about the bump stop forces and the design of the ball joints.

I am feeling slightly more confident going back to ball joints... BUT I REFUSE!

Well I forgot how much I like building stuff sooo the T100 beast is right about to be pushed over the edge from cool to badass...

This whole build has been a lot of fun to figure out but I think I am getting very close to a final build plan. Its very close to where i want it but not quite there yet.

So next week I will just go straight to ripping her apart again. Off with the front end and on with the Procomp Lift kit, Then Fab up the uniball conversion, Play with the angles and high misalignment spacers for maximum travel, Build a Heim steering set up, Mount the Coilovers, Then take it to the local Fab guy to install Bumps, Straps, Engine cage... And maybe beef up the spindles.

Unless you show up at my house with a MT prototype... Then my plan is kaput

Ive been doing this all during study breaks....

Haha I just drew up a print for the Lower ball joint.... At least the upper one is easier to do!

So the joint that failed was a Chinese joint after all. And it is incorrect that it has a round slot?

I think you are right on about the bump stop forces and the design of the ball joints.

I am feeling slightly more confident going back to ball joints... BUT I REFUSE!

Well I forgot how much I like building stuff sooo the T100 beast is right about to be pushed over the edge from cool to badass...

This whole build has been a lot of fun to figure out but I think I am getting very close to a final build plan. Its very close to where i want it but not quite there yet.

So next week I will just go straight to ripping her apart again. Off with the front end and on with the Procomp Lift kit, Then Fab up the uniball conversion, Play with the angles and high misalignment spacers for maximum travel, Build a Heim steering set up, Mount the Coilovers, Then take it to the local Fab guy to install Bumps, Straps, Engine cage... And maybe beef up the spindles.

Unless you show up at my house with a MT prototype... Then my plan is kaput

Last edited by Zpd426; 01-06-2014 at 08:55 PM.

#91

Registered User

Sorry i didnt get any action shots of your rig. just 2 pix and 1 video of when the truck was broken on the hill  pix on my thread if you wanna see the few that i snapped.

pix on my thread if you wanna see the few that i snapped.

pix on my thread if you wanna see the few that i snapped.

pix on my thread if you wanna see the few that i snapped.

#92

Registered User

Thread Starter

No prob. Thanks for the pics.

I may have been day dreaming when I wrote my last post... Still going to get that lift kit on with the uniballs but the other fab stuff will be a while

I may have been day dreaming when I wrote my last post... Still going to get that lift kit on with the uniballs but the other fab stuff will be a while

#93

Registered User

Nate.... After closer inspection you are right!

Ive been doing this all during study breaks....

Haha I just drew up a print for the Lower ball joint.... At least the upper one is easier to do!

So the joint that failed was a Chinese joint after all. And it is incorrect that it has a round slot?

I think you are right on about the bump stop forces and the design of the ball joints.

I am feeling slightly more confident going back to ball joints... BUT I REFUSE!

Well I forgot how much I like building stuff sooo the T100 beast is right about to be pushed over the edge from cool to badass...

This whole build has been a lot of fun to figure out but I think I am getting very close to a final build plan. Its very close to where i want it but not quite there yet.

So next week I will just go straight to ripping her apart again. Off with the front end and on with the Procomp Lift kit, Then Fab up the uniball conversion, Play with the angles and high misalignment spacers for maximum travel, Build a Heim steering set up, Mount the Coilovers, Then take it to the local Fab guy to install Bumps, Straps, Engine cage... And maybe beef up the spindles.

Unless you show up at my house with a MT prototype... Then my plan is kaput

Ive been doing this all during study breaks....

Haha I just drew up a print for the Lower ball joint.... At least the upper one is easier to do!

So the joint that failed was a Chinese joint after all. And it is incorrect that it has a round slot?

I think you are right on about the bump stop forces and the design of the ball joints.

I am feeling slightly more confident going back to ball joints... BUT I REFUSE!

Well I forgot how much I like building stuff sooo the T100 beast is right about to be pushed over the edge from cool to badass...

This whole build has been a lot of fun to figure out but I think I am getting very close to a final build plan. Its very close to where i want it but not quite there yet.

So next week I will just go straight to ripping her apart again. Off with the front end and on with the Procomp Lift kit, Then Fab up the uniball conversion, Play with the angles and high misalignment spacers for maximum travel, Build a Heim steering set up, Mount the Coilovers, Then take it to the local Fab guy to install Bumps, Straps, Engine cage... And maybe beef up the spindles.

Unless you show up at my house with a MT prototype... Then my plan is kaput

What I was saying about the slot being round was it started out as a slot but as the ball stud worked on it it became round and the ball stud popped out?

Last edited by BlazeN8; 01-07-2014 at 08:38 PM.

#94

Registered User

Quick question to T100 owners: have you ever caught any flak from hardcore yota guys b bing T100s. Seems like every once in a while someone will bad mouth mine and I think it's kind of funny.

#95

Registered User

Thread Starter

Nah usually people say "oh nice you dont see those very often"

If anyone were to give me flak I would just spread out in my big wide bench seat and show them the picture of my t100 towing the RZR out to the trails and then following it up everything

Nate I think the lazer cut pieces of the bracket may be a perfect solution. If I can integrate the Uniball into the bracket it would be very cool.

I think I still want to make a bolt on uniball set up just to do it. Maybe I will try bolt on first and then make an integrated one for the bracket. not sure yet.

If anyone were to give me flak I would just spread out in my big wide bench seat and show them the picture of my t100 towing the RZR out to the trails and then following it up everything

Nate I think the lazer cut pieces of the bracket may be a perfect solution. If I can integrate the Uniball into the bracket it would be very cool.

I think I still want to make a bolt on uniball set up just to do it. Maybe I will try bolt on first and then make an integrated one for the bracket. not sure yet.

#96

Registered User

I'll send you one side of the pair, that way you'll at least have it on hand for reference and mock up. No charge, I have your address. Shoot I was at the post office today renewing my Pass Port. Why didn't I think of it earlier!

#97

Registered User

BlazeN8 I love how you followup with your customers. Keep that relationship open and have great customer service. If my buddy decides to keep his 86 ifs pickup and not do an SAS. I will definitely have him take his business to you. awesome dude man. Hope I can meet you guys some day.

#98

Registered User

Redeth005, ZPD426 has been a good customer and has given me lots of great feed back as well as write up contributions. Zach has a machinist background and a good sense for the mechanical. I think its a win for everyone weather Zack comes up with a stand alone bolt on "BJ to Uni-ball conversion" OR something involving a newly designed UCA Extension Bracket that has a uni-ball option. I'm excited to see what he come up with.

#99

Registered User

Thread Starter

Thanks Nate! Good products make good customers!

I just found out I will be free from Friday to late February so I will get started pretty soon. Most likely I will just buy the Total Chaos lower uniball conversion because its less work for me to get the truck going with full uniballs. However the lower uniball conversion is very straightforward and that is something that can be addressed later. (and the TC one is CNC Machined sexy)

sexy)

Ill update as I go. First things first is Damage inspection though.

Nate, does the Blazeland extension bracket add much ball joint lift/spacing?

Based on my rough print I should be able to keep all the geometry the same. But I need to get a Uniball in hand first.

I just found out I will be free from Friday to late February so I will get started pretty soon. Most likely I will just buy the Total Chaos lower uniball conversion because its less work for me to get the truck going with full uniballs. However the lower uniball conversion is very straightforward and that is something that can be addressed later. (and the TC one is CNC Machined

sexy)

sexy)Ill update as I go. First things first is Damage inspection though.

Nate, does the Blazeland extension bracket add much ball joint lift/spacing?

Based on my rough print I should be able to keep all the geometry the same. But I need to get a Uniball in hand first.

Last edited by Zpd426; 01-08-2014 at 11:33 PM.