sway bar options?

#1

Registered User

Thread Starter

Join Date: Sep 2003

Location: Amarillo, Texas

Posts: 169

Likes: 0

Received 0 Likes

on

0 Posts

sway bar options?

Lately I've noticed my runner acting a little skittish on small abrupt bumps on the highway. Today I realized that my right hand sway bar link is broken. I figure this is not helping my handeling issue along with worn out shocks. The truck is stock as it sits but I'm about to get some OME springs and shocks all around. Is there a better alternative to the factory sway bar set up that may complemint the OME set up?

#2

Contributing Member

iTrader: (3)

Factory sway bar is fine, or I imagine there are stiffer bars available aftermarket, Sway-A-Way, Addco, etc.

Or, just get some new end-links the proper length for the lift you'll be putting on:

http://www.4crawler.com/4x4/CheapTri...#DisconnectsV2

Or, just get some new end-links the proper length for the lift you'll be putting on:

http://www.4crawler.com/4x4/CheapTri...#DisconnectsV2

#3

Sponsor

the other thing you can do its yank them out completely, i've ran NO sway bars for a while with out a problem, including smashing through mountain curvie roads.... you'll get better flex with out them too.

#4

Registered User

Join Date: Nov 2003

Location: Blowing Rock, NC

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

yeah no sway bars isn't too bad if you're off the pavement a good bit. I live in the mountains and it's actually kind of fun driving on the winding mountain roads with them off, but on the highway at 65+ it gets a little tricky. You really need to keep a good hand on the wheel and hope that you dont have to make any emergency maneuvers.

#5

Contributing Member

Join Date: Jul 2005

Location: Socal

Posts: 1,963

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ASU4runner

yeah no sway bars isn't too bad if you're off the pavement a good bit. I live in the mountains and it's actually kind of fun driving on the winding mountain roads with them off, but on the highway at 65+ it gets a little tricky. You really need to keep a good hand on the wheel and hope that you dont have to make any emergency maneuvers.

#6

Registered User

Thread Starter

Join Date: Sep 2003

Location: Amarillo, Texas

Posts: 169

Likes: 0

Received 0 Likes

on

0 Posts

I didn't even think about needing more length on the sway bar link with the added spring height. Am I correct in thinking that the sway bar end should be level with the lower control arm?

#7

Contributing Member

iTrader: (3)

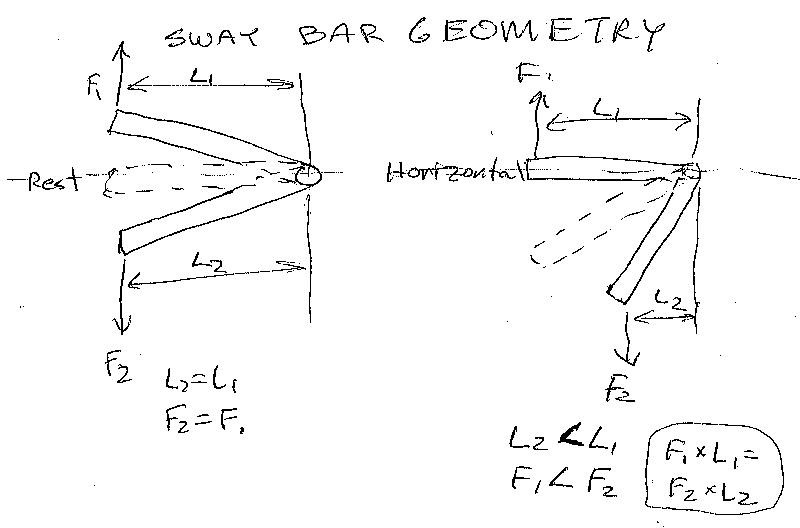

You bet, generally you want the ends of the sway bar to be sitting horizontal at rest. Why? Drive hard around a turn and one side of the bar is pushed up, one side pulls up on the opposite side of the suspension. If you start out horizontal on the end, the up and down angles are the same, so you get equal forces on the bar and suspension. If, for example you lifted the suspension and left the bar hanging down at some angle and went around the same corner, the one side would push the end of the bar up, closer to horizontal. The other side would be pulled down farther by the opposing suspension arm. With the near horizontal end, it would have the full leverage effect on the sway bar since the cosine of 90 degrees is 1.0. However the end of the bar that is down at some angle, would have a lesser amount of leverage, reduced by the cosine of it's angle. So this imbalance would result in the bar needing to be twisted farther to resist the cornering force, more twist = more lean in the vehicle or a less efficient sway bar. For example, assume the bar was down at 15 degrees due to the lift and in a turn it was twisted 15 up and down. That would leave the up side at 0 degrees (i.e. horizontal) and the down side down at 30 degrees. At a 30 degree angle the efective length of the end of the bar is now only 86.6% what is was when level (i.e. cos(30)=0.866). So that side can only provide 86% of the roll resistance as it could when level.

A good lift kit should have available a properly sized end-link replacement for the sway bars. Same thing with an LSPV bracket for the rear axle.

A good lift kit should have available a properly sized end-link replacement for the sway bars. Same thing with an LSPV bracket for the rear axle.

Last edited by 4Crawler; 10-08-2005 at 09:18 PM.

Trending Topics

#9

Originally Posted by 4Crawler

You bet, generally you want the ends of the sway bar to be sitting horizontal at rest. Why? Drive hard around a turn and one side of the bar is pushed up, one side pulls up on the opposite side of the suspension. If you start out horizontal on the end, the up and down angles are the same, so you get equal forces on the bar and suspension. If, for example you lifted the suspension and left the bar hanging down at some angle and went around the same corner, the one side would push the end of the bar up, closer to horizontal. The other side would be pulled down farther by the opposing suspension arm. With the near horizontal end, it would have the full leverage effect on the sway bar since the cosine of 90 degrees is 1.0. However the end of the bar that is down at some angle, would have a lesser amount of leverage, reduced by the cosine of it's angle. So this imbalance would result in the bar needing to be twisted farther to resist the cornering force, more twist = more lean in the vehicle or a less efficient sway bar. For example, assume the bar was down at 15 degrees due to the lift and in a turn it was twisted 15 up and down. That would leave the up side at 0 degrees (i.e. horizontal) and the down side down at 30 degrees. At a 30 degree angle the efective length of the end of the bar is now only 86.6% what is was when level (i.e. cos(30)=0.866). So that side can only provide 86% of the roll resistance as it could when level.

A good lift kit should have available a properly sized end-link replacement for the sway bars. Same thing with an LSPV bracket for the rear axle.

A good lift kit should have available a properly sized end-link replacement for the sway bars. Same thing with an LSPV bracket for the rear axle.

#10

Contributing Member

Join Date: Jul 2005

Location: Socal

Posts: 1,963

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 4Crawler

You bet, generally you want the ends of the sway bar to be sitting horizontal at rest. Why? Drive hard around a turn and one side of the bar is pushed up, one side pulls up on the opposite side of the suspension. If you start out horizontal on the end, the up and down angles are the same, so you get equal forces on the bar and suspension. If, for example you lifted the suspension and left the bar hanging down at some angle and went around the same corner, the one side would push the end of the bar up, closer to horizontal. The other side would be pulled down farther by the opposing suspension arm. With the near horizontal end, it would have the full leverage effect on the sway bar since the cosine of 90 degrees is 1.0. However the end of the bar that is down at some angle, would have a lesser amount of leverage, reduced by the cosine of it's angle. So this imbalance would result in the bar needing to be twisted farther to resist the cornering force, more twist = more lean in the vehicle or a less efficient sway bar. For example, assume the bar was down at 15 degrees due to the lift and in a turn it was twisted 15 up and down. That would leave the up side at 0 degrees (i.e. horizontal) and the down side down at 30 degrees. At a 30 degree angle the efective length of the end of the bar is now only 86.6% what is was when level (i.e. cos(30)=0.866). So that side can only provide 86% of the roll resistance as it could when level.

A good lift kit should have available a properly sized end-link replacement for the sway bars. Same thing with an LSPV bracket for the rear axle.

A good lift kit should have available a properly sized end-link replacement for the sway bars. Same thing with an LSPV bracket for the rear axle.

#13

Contributing Member

Originally Posted by ToferUOP

thanks for reminding why i hated statics so much.... lol jk, it wasnt that bad of a class

Thread

Thread Starter

Forum

Replies

Last Post

JookUpVandetti

86-95 Trucks & 4Runners

10

09-30-2015 08:58 AM