Joe's 1987 4Runner

#341

Registered User

Wow it looks great. You have a full house in the back seat. When I had a '97 4Runner and three kids under 3 I had to get an Odyssey. They could not touch.

#342

Registered User

Looks awesome dude, keep the pictures coming!

What are you gonna do about the side B pillar vent plastics? Do you have those just waiting on clips? Toyota still sells the clips for them thank god.

What are you gonna do about the side B pillar vent plastics? Do you have those just waiting on clips? Toyota still sells the clips for them thank god.

#344

Registered User

Thread Starter

Thanks guys, I appreciate it.

It is tight quarters in the back seat with all three girls on board- but they do okay. They've been riding like that in the '03 without incident. My wife noticed today, however, that there's no shoulder belt so Olive's booster seat is going to have to get changed out for a different seat. She's almost eight but still weighs only about 40 lbs.

I do have the B pillar pieces and the clips- but I'm trying to get them cleaned up. I repainted them Monday but they got rained on while the paint was still wet. I repainted them today and the paint bubbled up. So now I have to sand them down again and try one more time. I'm also hoping to refinish the badges- mine are in very poor condition so I'm looking into redoing the lettering.

ehatch, I'll take a picture of the crack in the dash for you- it's there. Some of the trim pieces are cracked and missing bits here and there. That thirty year old plastic is pretty brittle in places...

And you will catch up, I look forward to seeing it!

My wife and I have been looking for an excuse to spend a day or two down in Asheville, I may look you up when we head down there.

It is tight quarters in the back seat with all three girls on board- but they do okay. They've been riding like that in the '03 without incident. My wife noticed today, however, that there's no shoulder belt so Olive's booster seat is going to have to get changed out for a different seat. She's almost eight but still weighs only about 40 lbs.

I do have the B pillar pieces and the clips- but I'm trying to get them cleaned up. I repainted them Monday but they got rained on while the paint was still wet. I repainted them today and the paint bubbled up. So now I have to sand them down again and try one more time. I'm also hoping to refinish the badges- mine are in very poor condition so I'm looking into redoing the lettering.

ehatch, I'll take a picture of the crack in the dash for you- it's there. Some of the trim pieces are cracked and missing bits here and there. That thirty year old plastic is pretty brittle in places...

And you will catch up, I look forward to seeing it!

My wife and I have been looking for an excuse to spend a day or two down in Asheville, I may look you up when we head down there.

Last edited by ladybugRC; 01-18-2017 at 04:33 PM.

#345

Registered User

Join Date: Jan 2015

Location: Hendersonville NC

Posts: 652

Likes: 0

Received 0 Likes

on

0 Posts

From what i understand, booster seats are not to be used with lap only belts and it is safer to not use a booster seat. My son was 7 when i got mine and we did not use his booster. It sat him up to high, placing his belt on his thighs and in a crash he would have been thrown from the seat. With only they lap belt he was strapped in at the hips like you are supposed to be.

i will probably have my runner street legal in a couple of weeks since my schedule is changing back to my old shift so if you make it in asheville we can probably take the runners around the road

i will probably have my runner street legal in a couple of weeks since my schedule is changing back to my old shift so if you make it in asheville we can probably take the runners around the road

#346

Registered User

Thread Starter

100 mile update

I've been driving around town for about a week, working out some kinks. I have a small handful of issues/headaches that I'm having to tackle before I really start driving it full time. I still haven't had it on the highway, staying under 40 mph for now.

Issue #1: front end alignment

I have not yet been able to align it- the main reason for limited driving. The camber bolts are seized up good and proper. I applied heat and copious amounts of PB Blaster daily for a week and they won't budge. My front tires are over a degree out of adjustment so it's no good- driving on the edges of my nice new tires. I have sourced a pair of used lower control arms and camber bolts locally and I've ordered new bushings. I plan to get the replacement arms cleaned up, bushings pressed in and cut my rusty old ones out. It really sucks to have to dig into this front end again, but it's relatively minor compared to everything else I've been through to this point.

Issue #2: high idle

This is proving to cause me a little more anxiety as I'm not exactly sure where the problem is. At startup it idles fine but as it gets warmer the idle goes higher. At operating temp it idles around 1100 and the fuel cuts when my foot is on the brake as the idle creeps up. The idle adjust on the throttle body is bottomed out so I know something else is up. I've checked all my (new) vacuum lines and found no leaks. One thing that I did find was that tapping on the housing of the TPS with some pliers or a screwdriver caused the idle to increase. I don't know if this means the TPS is failing or not set properly or maybe the butterfly inside the throttle body is sticking? I set the timing with a timing light but maybe I should check it again. I do have a new coolant temperature sensor and I checked all my wiring. I think I will start with the TPS and go from there.

Issue #3: noisy valves

I know these motors commonly have a lot of valve chatter but mine feels a bit excessive. I need to check my clearances and adjust.

I made a short video of these last couple issues:

https://youtu.be/a1QiFwL22z8

As usual I welcome any advice you all might have. It's also worth mentioning that while I've not put a lot of miles on it yet, I have been really enjoying having it back!

Issue #1: front end alignment

I have not yet been able to align it- the main reason for limited driving. The camber bolts are seized up good and proper. I applied heat and copious amounts of PB Blaster daily for a week and they won't budge. My front tires are over a degree out of adjustment so it's no good- driving on the edges of my nice new tires. I have sourced a pair of used lower control arms and camber bolts locally and I've ordered new bushings. I plan to get the replacement arms cleaned up, bushings pressed in and cut my rusty old ones out. It really sucks to have to dig into this front end again, but it's relatively minor compared to everything else I've been through to this point.

Issue #2: high idle

This is proving to cause me a little more anxiety as I'm not exactly sure where the problem is. At startup it idles fine but as it gets warmer the idle goes higher. At operating temp it idles around 1100 and the fuel cuts when my foot is on the brake as the idle creeps up. The idle adjust on the throttle body is bottomed out so I know something else is up. I've checked all my (new) vacuum lines and found no leaks. One thing that I did find was that tapping on the housing of the TPS with some pliers or a screwdriver caused the idle to increase. I don't know if this means the TPS is failing or not set properly or maybe the butterfly inside the throttle body is sticking? I set the timing with a timing light but maybe I should check it again. I do have a new coolant temperature sensor and I checked all my wiring. I think I will start with the TPS and go from there.

Issue #3: noisy valves

I know these motors commonly have a lot of valve chatter but mine feels a bit excessive. I need to check my clearances and adjust.

I made a short video of these last couple issues:

https://youtu.be/a1QiFwL22z8

As usual I welcome any advice you all might have. It's also worth mentioning that while I've not put a lot of miles on it yet, I have been really enjoying having it back!

#347

Registered User

Joe - did you try an impact on your cam bolts? Not exactly the same, but one of my t-bar adjuster bolts was frozen, tried the soaking with wd40, tried a huge breaker bar, smacking nut with a hammer, nothing worked til I tried the impact.

Noisy valves - yeah, I just did mine, I adjusted them cold to a thousandth less than spec, and they are much quieter now.

High idle - check your idle air control valve, or aux air valve as it's called in the FSM, on the pre-89s it is prone to breakage. Normally when they break, they are spring loaded so they close up, which means you never really get a higher cold idle, but maybe yours is somehow open all the time. There is a simple test in the FSM, I believe at cold you pinch the air hose coming into the TB from the IACV and the idle should stumble.

Noisy valves - yeah, I just did mine, I adjusted them cold to a thousandth less than spec, and they are much quieter now.

High idle - check your idle air control valve, or aux air valve as it's called in the FSM, on the pre-89s it is prone to breakage. Normally when they break, they are spring loaded so they close up, which means you never really get a higher cold idle, but maybe yours is somehow open all the time. There is a simple test in the FSM, I believe at cold you pinch the air hose coming into the TB from the IACV and the idle should stumble.

#348

Registered User

Thread Starter

Thanks Cory, you're always helpful!

I have not yet tried the impact on the cam bolts- I figured that with the give from the bushings in there it wasn't going to do any good. But I will try it now!

Also, doing some troubleshooting on the IACV as you suggest- I do get the idle to drop when pinching that hose at cold, which tells me that the valve is open (as it should be at cold, right?) and letting extra air in to increase idle while the motor warms up.

If the valve is stuck open then I will also get the idle to drop when pinched warm- which it shouldn't, right? It closes when the motor is warm- if I am understanding all of this correctly. If that is the case then good chance that I've found my problem. The motor is running right now- warming up!

I cannot find information regarding the idle increase by tapping on the TPS. I don't have any of the other symptoms of a faulty/incorrectly adjusted TPS so I'd like to check some other things before messing with it.

I have not yet tried the impact on the cam bolts- I figured that with the give from the bushings in there it wasn't going to do any good. But I will try it now!

Also, doing some troubleshooting on the IACV as you suggest- I do get the idle to drop when pinching that hose at cold, which tells me that the valve is open (as it should be at cold, right?) and letting extra air in to increase idle while the motor warms up.

If the valve is stuck open then I will also get the idle to drop when pinched warm- which it shouldn't, right? It closes when the motor is warm- if I am understanding all of this correctly. If that is the case then good chance that I've found my problem. The motor is running right now- warming up!

I cannot find information regarding the idle increase by tapping on the TPS. I don't have any of the other symptoms of a faulty/incorrectly adjusted TPS so I'd like to check some other things before messing with it.

#349

Registered User

Thread Starter

Okay, engine nice and warm, pinching the aux air hose makes not difference, indicating that the valve is shut and apparently operating correctly.

I'm also wondering about O2 sensor. I've installed the LCE header, relocated the O2 sensor and I don't have a cat- maybe something there...

And, then again, timing? I did time the motor when it was first installed, but couldn't that be the problem??

I'm also wondering about O2 sensor. I've installed the LCE header, relocated the O2 sensor and I don't have a cat- maybe something there...

And, then again, timing? I did time the motor when it was first installed, but couldn't that be the problem??

#350

Registered User

Join Date: Jan 2015

Location: Hendersonville NC

Posts: 652

Likes: 0

Received 0 Likes

on

0 Posts

https://www.yotatech.com/forums/f116...e2-fix-286302/

try that for checking the tps.

first check it via the 4crawler link prior to removing it from the tb.

try that for checking the tps.

first check it via the 4crawler link prior to removing it from the tb.

#351

Registered User

iTrader: (-1)

If TPS not been removed already.

--TPS

Might be to late, but inspect the TPS signals while you're subjecting it to vibration. Aka probe it while you smack it, preferably with an analog meter for best response time. Might be a mechanical issue with the throttle plate bushings passing air, but that would be the first I recall anyone having that issue. The theory is the TPS is sealing the leak and when subjected to large jarring it leaks a little air passed.

If you get lots of electrical change its dirty wipers, lack of wiper spring preload, failing solder joints or just loose terminals. Fixable but might not be worth your time.

--Low to high idle

Kind of have some of this myself. It's not as high of a cold idle as I am expecting, does yours seem a bit low also? Think it's supposed to be in the 200-250 range, and brings it up to 1000 or just under. I've been meaning to clean up the intake air temperature sensor and give it a going over with the multimeter.

Both of the major warm up enrichment sensors, water and air temp, use a decrease in resistance as they heat up. This makes them suceptible to false readings, increase in wire/junction resistance due to heat soak, and could give the ECU a lower temperature reading. I thought the coolant flow should compensate for this however. Worth checking the wire loom isn't up against anything, and if so tieing it back.

Base timing is a quick test. Maybe it wasn't fully up to temp when that was set?

Vacuum leaks due to heat soak? Do you know exactly what size vacuum lines you were given? I've kind of ruled this one out by the usual tests, and gone a step further by putting hose clamps on anything I was questioning but ran out of tiny hose clamps. I should re do all these lines since the big box partstore gave me imperial hose, maybe using under sized metric hoses.

I'm probably starting to ramble, I keep going back and adding to paragraphs so I'll cut it off here.

Might be to late, but inspect the TPS signals while you're subjecting it to vibration. Aka probe it while you smack it, preferably with an analog meter for best response time. Might be a mechanical issue with the throttle plate bushings passing air, but that would be the first I recall anyone having that issue. The theory is the TPS is sealing the leak and when subjected to large jarring it leaks a little air passed.

If you get lots of electrical change its dirty wipers, lack of wiper spring preload, failing solder joints or just loose terminals. Fixable but might not be worth your time.

--Low to high idle

Kind of have some of this myself. It's not as high of a cold idle as I am expecting, does yours seem a bit low also? Think it's supposed to be in the 200-250 range, and brings it up to 1000 or just under. I've been meaning to clean up the intake air temperature sensor and give it a going over with the multimeter.

Both of the major warm up enrichment sensors, water and air temp, use a decrease in resistance as they heat up. This makes them suceptible to false readings, increase in wire/junction resistance due to heat soak, and could give the ECU a lower temperature reading. I thought the coolant flow should compensate for this however. Worth checking the wire loom isn't up against anything, and if so tieing it back.

Base timing is a quick test. Maybe it wasn't fully up to temp when that was set?

Vacuum leaks due to heat soak? Do you know exactly what size vacuum lines you were given? I've kind of ruled this one out by the usual tests, and gone a step further by putting hose clamps on anything I was questioning but ran out of tiny hose clamps. I should re do all these lines since the big box partstore gave me imperial hose, maybe using under sized metric hoses.

I'm probably starting to ramble, I keep going back and adding to paragraphs so I'll cut it off here.

Last edited by Co_94_PU; 02-02-2017 at 11:05 AM. Reason: Typo Do you, not so you

#352

Registered User

Joe - shoot, I thought for sure it would fail the IACV test.

Well, go thru all the free stuff first. I suppose it could be a vac leak somewhere downstream of that BVSV if you have that thing hooked up. I know Terry says he always changes the TPS whenever he rehabs a truck because they always seem to be problematic even if they test good per the FSM tests. I ran my truck for a while with no cat, it ran fine so I don't think the cat is at all necessary, other than to clean up the emissions.

How is the o-ring under the idle set screw? That makes it hard to get a consistent idle I think, not sure it would cause your problem, but who knows.

Well, go thru all the free stuff first. I suppose it could be a vac leak somewhere downstream of that BVSV if you have that thing hooked up. I know Terry says he always changes the TPS whenever he rehabs a truck because they always seem to be problematic even if they test good per the FSM tests. I ran my truck for a while with no cat, it ran fine so I don't think the cat is at all necessary, other than to clean up the emissions.

How is the o-ring under the idle set screw? That makes it hard to get a consistent idle I think, not sure it would cause your problem, but who knows.

#353

Registered User

Thread Starter

--TPS

Might be to late, but inspect the TPS signals while you're subjecting it to vibration. Aka probe it while you smack it, preferably with an analog meter for best response time. Might be a mechanical issue with the throttle plate bushings passing air, but that would be the first I recall anyone having that issue. The theory is the TPS is sealing the leak and when subjected to large jarring it leaks a little air passed.

If you get lots of electrical change its dirty wipers, lack of wiper spring preload, failing solder joints or just loose terminals. Fixable but might not be worth your time.

Might be to late, but inspect the TPS signals while you're subjecting it to vibration. Aka probe it while you smack it, preferably with an analog meter for best response time. Might be a mechanical issue with the throttle plate bushings passing air, but that would be the first I recall anyone having that issue. The theory is the TPS is sealing the leak and when subjected to large jarring it leaks a little air passed.

If you get lots of electrical change its dirty wipers, lack of wiper spring preload, failing solder joints or just loose terminals. Fixable but might not be worth your time.

--Low to high idle

Kind of have some of this myself. It's not as high of a cold idle as I am expecting, does yours seem a bit low also? Think it's supposed to be in the 200-250 range, and brings it up to 1000 or just under. I've been meaning to clean up the intake air temperature sensor and give it a going over with the multimeter.

Both of the major warm up enrichment sensors, water and air temp, use a decrease in resistance as they heat up. This makes them suceptible to false readings, increase in wire/junction resistance due to heat soak, and could give the ECU a lower temperature reading. I thought the coolant flow should compensate for this however. Worth checking the wire loom isn't up against anything, and if so tieing it back.

Base timing is a quick test. Maybe it wasn't fully up to temp when that was set?

Vacuum leaks due to heat soak? Do you know exactly what size vacuum lines you were given? I've kind of ruled this one out by the usual tests, and gone a step further by putting hose clamps on anything I was questioning but ran out of tiny hose clamps. I should re do all these lines since the big box partstore gave me imperial hose, maybe using under sized metric hoses.

Kind of have some of this myself. It's not as high of a cold idle as I am expecting, does yours seem a bit low also? Think it's supposed to be in the 200-250 range, and brings it up to 1000 or just under. I've been meaning to clean up the intake air temperature sensor and give it a going over with the multimeter.

Both of the major warm up enrichment sensors, water and air temp, use a decrease in resistance as they heat up. This makes them suceptible to false readings, increase in wire/junction resistance due to heat soak, and could give the ECU a lower temperature reading. I thought the coolant flow should compensate for this however. Worth checking the wire loom isn't up against anything, and if so tieing it back.

Base timing is a quick test. Maybe it wasn't fully up to temp when that was set?

Vacuum leaks due to heat soak? Do you know exactly what size vacuum lines you were given? I've kind of ruled this one out by the usual tests, and gone a step further by putting hose clamps on anything I was questioning but ran out of tiny hose clamps. I should re do all these lines since the big box partstore gave me imperial hose, maybe using under sized metric hoses.

I'm not too worried about vacuum leaks as all my lines are new; they are silicon lines from LCE, specifically for this motor, correct sizes.

I'm not sure how well I'd be able to time the motor at this point, especially if the TPS is in fact going bad. It idles way too high at temp to get it timed properly, I think.

Either way, like you, I'll be spending some time with the multimeter hunting this down.

Thanks for the suggestions!

#354

Registered User

Thread Starter

Joe - shoot, I thought for sure it would fail the IACV test.

Well, go thru all the free stuff first. I suppose it could be a vac leak somewhere downstream of that BVSV if you have that thing hooked up. I know Terry says he always changes the TPS whenever he rehabs a truck because they always seem to be problematic even if they test good per the FSM tests. I ran my truck for a while with no cat, it ran fine so I don't think the cat is at all necessary, other than to clean up the emissions.

How is the o-ring under the idle set screw? That makes it hard to get a consistent idle I think, not sure it would cause your problem, but who knows.

Well, go thru all the free stuff first. I suppose it could be a vac leak somewhere downstream of that BVSV if you have that thing hooked up. I know Terry says he always changes the TPS whenever he rehabs a truck because they always seem to be problematic even if they test good per the FSM tests. I ran my truck for a while with no cat, it ran fine so I don't think the cat is at all necessary, other than to clean up the emissions.

How is the o-ring under the idle set screw? That makes it hard to get a consistent idle I think, not sure it would cause your problem, but who knows.

As I said before, I see a day of testing with my multimeter in my future...

And as for the o-ring: it is hard, it is old and it probably should be replaced. I'll add it to the list. Like you, I don't think it is causing my problem as I have that set screw all the way down.

#355

Registered User

Join Date: Jan 2015

Location: Hendersonville NC

Posts: 652

Likes: 0

Received 0 Likes

on

0 Posts

I used thread tape on my idle screw. Works perfect for me.

a side note, i had my idle way to high on my rig as well when i first started it and had to adjust the plastic power steering idle screw in alot to adjust properly. Give that a look as well

a side note, i had my idle way to high on my rig as well when i first started it and had to adjust the plastic power steering idle screw in alot to adjust properly. Give that a look as well

#356

Registered User

iTrader: (-1)

Red herring

I had a sticky TPS like his, but mine was just full of mud and cleaning fixed that issue.

All the idle screw talk has me wondering, if you have it bottomed out where is your idle air coming from. Since the cold idle valve seems to be working just fine. That only leaves the bypass for the AC&PS, or the PCV system as major intake points.

All the idle screw talk has me wondering, if you have it bottomed out where is your idle air coming from. Since the cold idle valve seems to be working just fine. That only leaves the bypass for the AC&PS, or the PCV system as major intake points.

#357

Registered User

Join Date: Jan 2015

Location: Hendersonville NC

Posts: 652

Likes: 0

Received 0 Likes

on

0 Posts

I had a sticky TPS like his, but mine was just full of mud and cleaning fixed that issue.

All the idle screw talk has me wondering, if you have it bottomed out where is your idle air coming from. Since the cold idle valve seems to be working just fine. That only leaves the bypass for the AC&PS, or the PCV system as major intake points.

All the idle screw talk has me wondering, if you have it bottomed out where is your idle air coming from. Since the cold idle valve seems to be working just fine. That only leaves the bypass for the AC&PS, or the PCV system as major intake points.

This is an excellent point. The first thing to do with a tps check is to check for proper throttle plate adjustment.

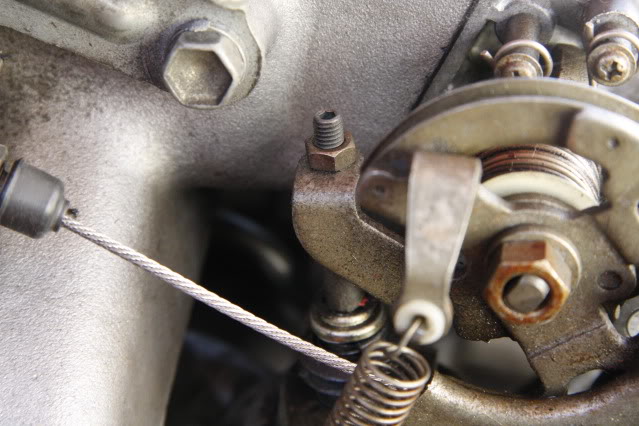

i removed the valve/diaphragm from my throttle body, it was causing the plate to stick open.

do not over tighten the throttle cable

once that checks out the pcv valve and dip stick seal should be checked. The seal on the dipstick can let un metered air into the intake manifold.

after that and all vacuum hoses check out the aux air valve has a check and adjustment.

i adjusted and cleaned mine.

Then the tps adjustment etc

#358

Registered User

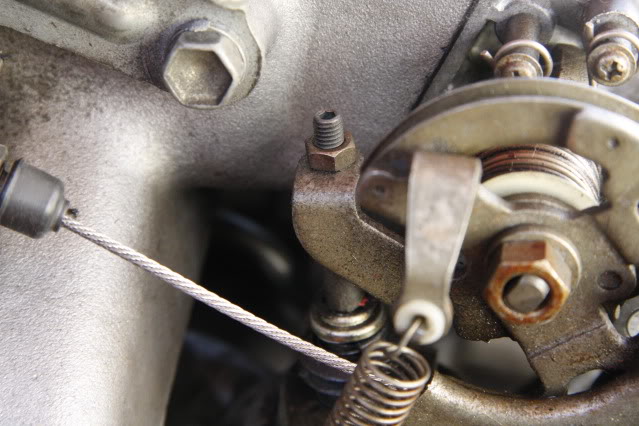

I'm thinking your sticking idle may be caused by the dashpot. Pretty common on the 22re. Simplest way to find out is to just adjust it out until the throttle linkage stop plate doesn't depress the sprung pin.

#359

Registered User

Thread Starter

So that issue is resolved. I'm still working out the kinks on the front end. Cory, I had no luck budging those cam bolts with an impact. I was able to remove the nuts but the bolts are SEIZED in those sleeves like I've never seen. A local guy who has a bunch of parts rigs sold me the lower control arms and four cam bolts for $150. While I was at the garage yesterday I cleaned them up, removed the old bushings and got them ready for paint. A buddy of mine works at a local 4x4 center and offered to let me bring the truck over after-hours and put it up on the lift to swap out the LCAs. My new bushings should arrive today or tomorrow and in the next few days I intend to take him up on his offer and get everything changed out. I'm sure this will be much easier on the lift than on my back.

Last thing will be adjusting the valves- a couple of the intake valves are really clicking. I was considering letting the motor get some more miles on it before doing the valve adjustment, but I think I'll go ahead and do that now and then again after a few thousand miles if it needs it.

I also put the '03 4Runner up on Craigslist... I won't have a backup vehicle to drive once that sells so I hope to get everything smoothed out soon and start driving the '87 daily!

#360

Registered User

My idle was intermittently stuck high for years because of that dashpot. I understand it serves a purpose (prevents sudden air cut if you let off the throttle too quick), but I haven't noticed much difference without it.

First saw this thread almost a year ago, nice work!

First saw this thread almost a year ago, nice work!