OM617 into 1987 4Runner SR5

#81

I have a ? for anyone in the om617 toyota swap.

I have a Mercedes 300CDturbo in my 89 Toyota extended cab truck (veggie truck). I had a very weak truck until I removed the diagram in the ALDA to enrich the fuel. Now its a pleasant truck to drive but I have concerns because the the turbo pressure runs 80% of the time at 8-10 lbs of pressure and I don’t want to burn a hole in my piston. The piston compression is 320lbs. So I figure it can handle more than normal pressure I could put a exhaust temperature gauge in, but they are expensive and I wouldn’t know what I was looking at. Does anyone know if I should be concerned?? Thanks Kcin123

Ps I noticed your motor mounts are at a steep angle. I tried that. but the motor was too heavy so I changed the angle of the rubber.

I have a Mercedes 300CDturbo in my 89 Toyota extended cab truck (veggie truck). I had a very weak truck until I removed the diagram in the ALDA to enrich the fuel. Now its a pleasant truck to drive but I have concerns because the the turbo pressure runs 80% of the time at 8-10 lbs of pressure and I don’t want to burn a hole in my piston. The piston compression is 320lbs. So I figure it can handle more than normal pressure I could put a exhaust temperature gauge in, but they are expensive and I wouldn’t know what I was looking at. Does anyone know if I should be concerned?? Thanks Kcin123

Ps I noticed your motor mounts are at a steep angle. I tried that. but the motor was too heavy so I changed the angle of the rubber.

#82

Registered User

Thread Starter

Nice build! Have you checked out Dakota Digital's tach interface that uses a flywheel gear tooth sensor and sends a signal to your stock tach. (link below)

http://www.dakotadigital.com/index.c...rod/prd129.htm

http://www.dakotadigital.com/index.c...rod/prd129.htm

Luckily someone dissected and made the schematic for the tach amp, which makes it easy to see how MB filtered the sensor yadda yadda. It's pretty interesting stuff. I may be able to do this with a 555 timer and a simple circuit? Either way, I have the arduino driving the Toyota tach with a square wave now. My only issue is reading the signal from the tach amp- so I will try the crank pickup next!

Luckily someone dissected and made the schematic for the tach amp, which makes it easy to see how MB filtered the sensor yadda yadda. It's pretty interesting stuff. I may be able to do this with a 555 timer and a simple circuit? Either way, I have the arduino driving the Toyota tach with a square wave now. My only issue is reading the signal from the tach amp- so I will try the crank pickup next!

Don't fret on the power until you get it dialed in, and having the alda intake fitting clean and adjusted properly will make all of the difference on the low-end. I also saw a big improvement with rebuilding my injectors with Monark nozzles. Greazzer on STD is a known, trusted rebuilder.

Makes such a massive difference when it is out of adjustment. Still, my truck feels a little anemic off the line. Not that I was expecting something with gobs of get up, but it is a bit underwhelming in terms of power. The truck just feels bigger and heavier now, more like a bear than the gazelle it was. Once at speed, it has a lot more staying punch than it did before and cruises so so well. Off the line though, it falls on its face unless I really commit to giving it some get up- which makes for a pretty lackluster stop & go traffic feel- actually sometimes it is annoyingly slow because I like to zip in and out of tight spaces and I make quick driving decisions. So far, having the new motor in there is making me relearn how to drive the truck (because it isn't so zippy anymore around town). I feel like I have to plan things more now, as if I was driving a box truck or other huge vehicle. It equates for a different driving experience. Jury is still out whether I like it more or less. If I can get some more low end power out of this motor, I'll be SO much happier with the swap overall.

Makes such a massive difference when it is out of adjustment. Still, my truck feels a little anemic off the line. Not that I was expecting something with gobs of get up, but it is a bit underwhelming in terms of power. The truck just feels bigger and heavier now, more like a bear than the gazelle it was. Once at speed, it has a lot more staying punch than it did before and cruises so so well. Off the line though, it falls on its face unless I really commit to giving it some get up- which makes for a pretty lackluster stop & go traffic feel- actually sometimes it is annoyingly slow because I like to zip in and out of tight spaces and I make quick driving decisions. So far, having the new motor in there is making me relearn how to drive the truck (because it isn't so zippy anymore around town). I feel like I have to plan things more now, as if I was driving a box truck or other huge vehicle. It equates for a different driving experience. Jury is still out whether I like it more or less. If I can get some more low end power out of this motor, I'll be SO much happier with the swap overall. I have to be honest, I miss the 22re a little bit.

Maybe I am just missing something dumb, or my IP is on the fritz, or who knows what else. Maybe I am just too used to riding motorcycles

Something doesn't seem quite right.

Something doesn't seem quite right.

#83

Jenny,

Regards to low end torque. I completed this swap into a 93 Pickup last year. I recently changed the stock turbocharger (Garret T3) out for a Mitusbishi TD04HL-19T. This is a newer unit found in Volvos and early 2000s Saabs. It spools much quicker than the stock unit and completely changed the driving characteristics of the engine in my case. I was able to return the ALDA to stock settings - charge air pressure increases more quickly allowing the ALDA to add fuel quicker than stock.

Installation required several things:

-The nice federal Mercedes air cleaner no longer fit, I used the California version which was harder to fit neatly, but works very well.

-Plumb coolant lines as the bearing housing is water cooled

-Convert the oil feed line to braided line with AN fittings.

-Convert drain line to flexible (still working on a better solution for this)

-Use a TD04/T3 Adapter on the exhaust manifold (Ebay).

Again, this made the truck a much better driving experience. I'm in the process of swapping the R150 manual trans for a Chevy 700R4 automatic with high stall converter. The combination of the quick-spooling turbo and high stall torque converter should let the engine reach the torque band quite quickly.

Best of luck with your project!

EDIT: Also be sure to check your timing chain stretch. Excess wear in the chain reduces IP and cam timing which reduces power, even a few degrees will make a 617 feel sluggish.

Regards to low end torque. I completed this swap into a 93 Pickup last year. I recently changed the stock turbocharger (Garret T3) out for a Mitusbishi TD04HL-19T. This is a newer unit found in Volvos and early 2000s Saabs. It spools much quicker than the stock unit and completely changed the driving characteristics of the engine in my case. I was able to return the ALDA to stock settings - charge air pressure increases more quickly allowing the ALDA to add fuel quicker than stock.

Installation required several things:

-The nice federal Mercedes air cleaner no longer fit, I used the California version which was harder to fit neatly, but works very well.

-Plumb coolant lines as the bearing housing is water cooled

-Convert the oil feed line to braided line with AN fittings.

-Convert drain line to flexible (still working on a better solution for this)

-Use a TD04/T3 Adapter on the exhaust manifold (Ebay).

Again, this made the truck a much better driving experience. I'm in the process of swapping the R150 manual trans for a Chevy 700R4 automatic with high stall converter. The combination of the quick-spooling turbo and high stall torque converter should let the engine reach the torque band quite quickly.

Best of luck with your project!

EDIT: Also be sure to check your timing chain stretch. Excess wear in the chain reduces IP and cam timing which reduces power, even a few degrees will make a 617 feel sluggish.

Last edited by usmma2013; 12-16-2015 at 07:36 AM.

#84

Registered User

Join Date: Jan 2010

Location: Vancouver, Wa

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

That's exactly what I've been working on, except I haven't gone straight to the crank pickup. That's a great idea  Luckily someone dissected and made the schematic for the tach amp, which makes it easy to see how MB filtered the sensor yadda yadda. It's pretty interesting stuff. I may be able to do this with a 555 timer and a simple circuit?

Luckily someone dissected and made the schematic for the tach amp, which makes it easy to see how MB filtered the sensor yadda yadda. It's pretty interesting stuff. I may be able to do this with a 555 timer and a simple circuit?

Luckily someone dissected and made the schematic for the tach amp, which makes it easy to see how MB filtered the sensor yadda yadda. It's pretty interesting stuff. I may be able to do this with a 555 timer and a simple circuit?

Luckily someone dissected and made the schematic for the tach amp, which makes it easy to see how MB filtered the sensor yadda yadda. It's pretty interesting stuff. I may be able to do this with a 555 timer and a simple circuit?I just got ALDA back on today and adjusted it  Makes such a massive difference when it is out of adjustment. Still, my truck feels a little anemic off the line. Not that I was expecting something with gobs of get up, but it is a bit underwhelming in terms of power. The truck just feels bigger and heavier now, more like a bear than the gazelle it was.

Makes such a massive difference when it is out of adjustment. Still, my truck feels a little anemic off the line. Not that I was expecting something with gobs of get up, but it is a bit underwhelming in terms of power. The truck just feels bigger and heavier now, more like a bear than the gazelle it was.

Makes such a massive difference when it is out of adjustment. Still, my truck feels a little anemic off the line. Not that I was expecting something with gobs of get up, but it is a bit underwhelming in terms of power. The truck just feels bigger and heavier now, more like a bear than the gazelle it was.

Makes such a massive difference when it is out of adjustment. Still, my truck feels a little anemic off the line. Not that I was expecting something with gobs of get up, but it is a bit underwhelming in terms of power. The truck just feels bigger and heavier now, more like a bear than the gazelle it was. Turning up the turbo helped when I was already at speed, (I run ~15+psi now, which should make the motor behave like a 4.5L; at least volumetrically). (A friend of mine with a 1992 3.0 said he thought the OM617 FJ80 moves better than his rig does, even upon acceleration. I think your motor has a lot of room to grow. What do your valves look like? Since they need to be adjusted so often, they could be out of adjustment.)

The things that made the most dramatic difference for low end torque for me were:

1.-Monark nozzle tips & rebuilt injectors

2.-Adjust fuel bypass spring to spec.

3.-Turn up turbo to spool more quickly

(Of course use prudence, a pyrometer, and fully document and IP changes made when you get there!)

Bottom Line:

- My FJ is not a powerhouse or a stallion off-the-line, but my mpg went from 11.9 to ~16-18 mpg with a small increase in usable power. (A lot of this was using a manual transmission, vs the factory AWD beast).

- My 1995 4Runner with a 3.4 5vze (1996), is a stallion off the line, has a crossflow head, OBDII, merges well in traffic while laden, with 31's and bumpers/sliders/winch, etc. , but still weighs less than the FJ.

Gas rigs are often more spirited than their diesel counterparts, but at the expense of torque and efficiency.

This guy is moving a unimog with the Om617:

http://www.benzworld.org/forums/w123...uel-boost.html

((There is also some talk in the works of modified delivery valves and such, but that would be after you get everything else dialed in.))

Have you run the motor on strait diesel purge?

You can usually get it from NAPA.

http://www.napaonline.com/Catalog/Ca...005_0119204330

It's basically Strange German Magic-in-a-Can; (or you could check the MSDS). But it comes highly recommended by even Mercedes as an IP tune up procedure. Next time you swap your fuel filter, run the Lubro through the fuel system for a can or two before changing the old. When you replace the filter, top off your PS res w/ATF, and fill the new filter (inverted) with atf.

Good Luck!

#87

Registered User

Join Date: Jan 2010

Location: Vancouver, Wa

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

I have autometer (200-2000F), because I got a deal.

http://www.superturbodiesel.com/std/...ad.php?tid=183

(Feel free to PM me or start a new thread with your build if you have more questions, we'd all dig seeing your build progress!)

http://www.superturbodiesel.com/std/...ad.php?tid=183

(Feel free to PM me or start a new thread with your build if you have more questions, we'd all dig seeing your build progress!)

#88

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

To get your factory tach working, below will make it work. To adjust the tachs, in the SR5 gauge swap thread, there is a picture of where and how to adjust it, I can find it later for you later if needed. I am only guessing but I as long as you run the wire to the negative side of the MB coil, everything should work as far as the tach goes.

Copied from my thread..

Starting on my tachometer and what is needed to get the tachometer working.

I then ran a wire to the negative side of the coil, on a carburator coil it is a little different then a standard coil you are most used to seeing. This truck didnt come with the SR5 guage so I added it. If your truck is not Plug and Play like some are, you need to run a wire from the negative side of the coil to the little "p" to make the tach work.

Then what I did so as not to short out the electrical run beside it. I placed a piece of electrical tape over the little "p" and crimped a wire to the smallest connector that I could find.

I used tape for insulation and to make my connection to the "p".

Run your wire to this point.

Copied from my thread..

Starting on my tachometer and what is needed to get the tachometer working.

I then ran a wire to the negative side of the coil, on a carburator coil it is a little different then a standard coil you are most used to seeing. This truck didnt come with the SR5 guage so I added it. If your truck is not Plug and Play like some are, you need to run a wire from the negative side of the coil to the little "p" to make the tach work.

Then what I did so as not to short out the electrical run beside it. I placed a piece of electrical tape over the little "p" and crimped a wire to the smallest connector that I could find.

I used tape for insulation and to make my connection to the "p".

Run your wire to this point.

#89

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

Here is the adjustment and thread for more information,

You could try this https://www.yotatech.com/forums/f116...06/index6.html

You could try this https://www.yotatech.com/forums/f116...06/index6.html

Here are the pics:

The adjustment potentiometer:

if you have another tach hooked up that you're using to adjust, you can sneak a thin and long screw driver in there to adjust it (I had to gently push against the pot with the driver to bend it back slightly and seat, but this shouldn't cause any harm.)

if you don't have another tach to adjust by then you can pull it out by removing these 3 screws:

then use your multimeter to measure resistance across these two points:

The V6 was originally setup with a value of 44.9K ohms, I adjusted it to 63.8K ohms. I would recommend people converting a 6cyl cluster to a 4cyl to simply add 20K ohms to whatever they started with.

This cluster came out of a 1992 4Runner Automatic V6 SR5, and I installed it in my 1989 Pikcup 5-speed 22re Deluxe, so considering that, you can make anything work with anything.

---------

I have another problem though, I went to swap out the oil pressure switch and the electrical connector wont work with the new sensor, it's missing the slot to slide on sideways... so I'll need to find the proper connector before I'll have a working pressure gauge. In the mean time I've just left it disconnected and taped off so I don't damage the new gauge.

so I'll need to find the proper connector before I'll have a working pressure gauge. In the mean time I've just left it disconnected and taped off so I don't damage the new gauge.

also to go along with that the old sensor required a 27mm socket to remove, the new sensor required a 9/16th open ended wrench to tighten down.

-----------

Oh and alpinexss, I got my cluster right in the marketplace section here, there were at least 5 of them for sale, I got mine from a listing that was a good 6 months old, and I payed way less than similar eBay listings.

I'd rather support other yotatech members anyway.

The adjustment potentiometer:

if you have another tach hooked up that you're using to adjust, you can sneak a thin and long screw driver in there to adjust it (I had to gently push against the pot with the driver to bend it back slightly and seat, but this shouldn't cause any harm.)

if you don't have another tach to adjust by then you can pull it out by removing these 3 screws:

then use your multimeter to measure resistance across these two points:

The V6 was originally setup with a value of 44.9K ohms, I adjusted it to 63.8K ohms. I would recommend people converting a 6cyl cluster to a 4cyl to simply add 20K ohms to whatever they started with.

This cluster came out of a 1992 4Runner Automatic V6 SR5, and I installed it in my 1989 Pikcup 5-speed 22re Deluxe, so considering that, you can make anything work with anything.

---------

I have another problem though, I went to swap out the oil pressure switch and the electrical connector wont work with the new sensor, it's missing the slot to slide on sideways...

so I'll need to find the proper connector before I'll have a working pressure gauge. In the mean time I've just left it disconnected and taped off so I don't damage the new gauge.

so I'll need to find the proper connector before I'll have a working pressure gauge. In the mean time I've just left it disconnected and taped off so I don't damage the new gauge.also to go along with that the old sensor required a 27mm socket to remove, the new sensor required a 9/16th open ended wrench to tighten down.

-----------

Oh and alpinexss, I got my cluster right in the marketplace section here, there were at least 5 of them for sale, I got mine from a listing that was a good 6 months old, and I payed way less than similar eBay listings.

I'd rather support other yotatech members anyway.

#91

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

Thanks.. I just had a DUH!!! moment. You are correct on that and just so used to working on gasoline motor questions. I have been following this thread and is something I would like to do some day as well.

My dumbutt moment has passed over me now.lol

Please post any information on getting a tach to work on a diesel. I would be intrested in seeing how that works and just something I just never thought of on a diesel and tach.

My dumbutt moment has passed over me now.lol

Please post any information on getting a tach to work on a diesel. I would be intrested in seeing how that works and just something I just never thought of on a diesel and tach.

Last edited by Terrys87; 12-16-2015 at 03:34 PM.

#93

Registered User

Thread Starter

I am able to accurately move/animate the tach with the arduino, but yeah an actual circuit looks way more appealing and trustworthy.

I might end up going with the dakota digital flywheel thing, just whatever I have time/patience/money for.

usm- that sounds really promising, changing the turbo. There seems to also be a lot of talk over VNT turbos, maybe that Mitsubishi is? Either way yeah, having spool up lower in the power band I'm sure changes everything. Definitely going to look into this further! Do you think regearing my diffs would be a good idea? I have 31s

Cadin- Thanks a million for all the great tips re: low end. It's definitely the thing I am researching the most right now because it is instant gratification, so it's music to my ears seeing your suggestions. I didn't have time today to actually test IP timing (I don't have a dripper yet anyway) but I did score it for reference before moving it about 1mm (at the score) towards the block, advancing it. It made a noticeable improvement that passed the placebo test.

I am pretty certain I have some significant chain stretch going on. Now just looking forward to getting it to 26deg BTDC exactly. I am going to wait to set the timing properly before messing with timing anymore, was just curious to see if it made a difference, and it did.

I also took the muffler out of the exhaust and replaced it with straight pipe. Then earlier too, I got a good sized K&N on the intake instead of the stock air box. The difference from yesterday vs today is great, both in terms of the way it sounds and the way it drives thanks to the timing adjustment.

I really need to get a pyrometer asap! Imma order one tonight, autometer ultra lite- boost & pyro

Oh yeah, and I have been looking at a few stores but couldn't find the diesel purge anywhere. Good to know NAPA has it!! Thanks Cadin!

Terry- That info was still useful to me when I was trying to make the tachometer my puppet so thanks

Some pics

simplified filter setup... nice breather routing (temporary until I make an oil catch)

(temporary until I make an oil catch)

still some tidying & mounting to do but you get the picture

arduino controlling toyota tach

Really starting to dig it!

Video: https://vimeo.com/149360085

I might end up going with the dakota digital flywheel thing, just whatever I have time/patience/money for.

usm- that sounds really promising, changing the turbo. There seems to also be a lot of talk over VNT turbos, maybe that Mitsubishi is? Either way yeah, having spool up lower in the power band I'm sure changes everything. Definitely going to look into this further! Do you think regearing my diffs would be a good idea? I have 31s

Cadin- Thanks a million for all the great tips re: low end. It's definitely the thing I am researching the most right now because it is instant gratification, so it's music to my ears seeing your suggestions. I didn't have time today to actually test IP timing (I don't have a dripper yet anyway) but I did score it for reference before moving it about 1mm (at the score) towards the block, advancing it. It made a noticeable improvement that passed the placebo test.

I am pretty certain I have some significant chain stretch going on. Now just looking forward to getting it to 26deg BTDC exactly. I am going to wait to set the timing properly before messing with timing anymore, was just curious to see if it made a difference, and it did.

I also took the muffler out of the exhaust and replaced it with straight pipe. Then earlier too, I got a good sized K&N on the intake instead of the stock air box. The difference from yesterday vs today is great, both in terms of the way it sounds and the way it drives thanks to the timing adjustment.

I really need to get a pyrometer asap! Imma order one tonight, autometer ultra lite- boost & pyro

Oh yeah, and I have been looking at a few stores but couldn't find the diesel purge anywhere. Good to know NAPA has it!! Thanks Cadin!

Terry- That info was still useful to me when I was trying to make the tachometer my puppet so thanks

Some pics

simplified filter setup... nice breather routing

(temporary until I make an oil catch)

(temporary until I make an oil catch)

still some tidying & mounting to do but you get the picture

arduino controlling toyota tach

Really starting to dig it!

Video: https://vimeo.com/149360085

#94

Registered User

Thread Starter

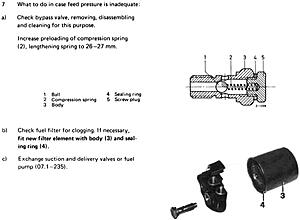

What can I say, Cadin! Your post inspired me to take action fast.

I pulled the fuel bypass spring, and whaddya know

Bent it to near 27mm and reinstalled. It took a surprising amount of force to resize it, and I went slowly and carefully in increments

Butt dyno showed moderate improvements across the board, but I didn't really try pushing it. It seemed to have more idle crawl torque when I pulled out of the driveway and idle sounded deeper and very smooth, but too early to rule out placebo for all of this. it's been rocking the truck a slight bit when warm, so I wonder if it will be smooth tomorrow once it warms up. It also makes me wonder if I need to bring the rack damper spring back into spec as well...

The most drastic new change is that the primer pump is 3X harder to press, and it is no longer spitting bubbles into the line above. No more air in my fuel lines, the bypass spring was the culprit!

per the fsm:

I pulled the fuel bypass spring, and whaddya know

Bent it to near 27mm and reinstalled. It took a surprising amount of force to resize it, and I went slowly and carefully in increments

Butt dyno showed moderate improvements across the board, but I didn't really try pushing it. It seemed to have more idle crawl torque when I pulled out of the driveway and idle sounded deeper and very smooth, but too early to rule out placebo for all of this. it's been rocking the truck a slight bit when warm, so I wonder if it will be smooth tomorrow once it warms up. It also makes me wonder if I need to bring the rack damper spring back into spec as well...

The most drastic new change is that the primer pump is 3X harder to press, and it is no longer spitting bubbles into the line above. No more air in my fuel lines, the bypass spring was the culprit!

per the fsm:

Last edited by jennygirl; 12-17-2015 at 10:43 PM.

#95

Registered User

Thread Starter

Reading some other forums, I just realized that low feed pressure may actually retard timing of the IP fill and higher feed pressure would advance it.

Maybe I should reset my IP timing back to factory to be on the safe side, because I don't know how much I advanced it already earlier today. With chain stretch, though, it's probably fine...

Maybe I should reset my IP timing back to factory to be on the safe side, because I don't know how much I advanced it already earlier today. With chain stretch, though, it's probably fine...

#96

Registered User

Join Date: Jan 2010

Location: Vancouver, Wa

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

Yaaay! I love the stuff that can be knocked out quickly for no monies!

If you are getting shake at idle, resetting the rack damper should settle it down.

Are you getting the puff of smoke that clears upon take-off with the ALDA adjust?

(The lubro treatment helped with my rough idle as well. You can get it from the Amazon, if you cannot source it locally. (Though how the rain forest makes all of these wonders is beyond me )).

)).

If you are getting shake at idle, resetting the rack damper should settle it down.

Are you getting the puff of smoke that clears upon take-off with the ALDA adjust?

(The lubro treatment helped with my rough idle as well. You can get it from the Amazon, if you cannot source it locally. (Though how the rain forest makes all of these wonders is beyond me

)).

)).

#97

Registered User

Thread Starter

Cadin, yeah! I set the rack damper bolt all the way in but it was already pretty much maxed, I think I only got about 1/4 turn before it hit the stop. Should have the new bosch one arriving early next week, ordered it last night  I am sure that spring is totally worn out. The shake seemed diminished today, I think the fuel bypass spring adjustment helped a lot. It is idling really really nice. There is still a subtle hint of a wobble.

I am sure that spring is totally worn out. The shake seemed diminished today, I think the fuel bypass spring adjustment helped a lot. It is idling really really nice. There is still a subtle hint of a wobble.

And yeah, getting that puff of smoke that clears upon takeoff. I think ALDA must be pretty close!

Funny that you mentioned the liquimoly stuff again, I just got back from NAPA and they had two cans left. Gonna do that today!

Valve adjustment tomorrow morning

I am sure that spring is totally worn out. The shake seemed diminished today, I think the fuel bypass spring adjustment helped a lot. It is idling really really nice. There is still a subtle hint of a wobble.

I am sure that spring is totally worn out. The shake seemed diminished today, I think the fuel bypass spring adjustment helped a lot. It is idling really really nice. There is still a subtle hint of a wobble.And yeah, getting that puff of smoke that clears upon takeoff. I think ALDA must be pretty close!

Funny that you mentioned the liquimoly stuff again, I just got back from NAPA and they had two cans left. Gonna do that today!

Valve adjustment tomorrow morning

#98

Registered User

Join Date: Jan 2010

Location: Vancouver, Wa

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

Heya Jenny, any luck with the liquimoly? (It's always fun to see how dirty the solution gets, after it's been cycling through for a bit!)

How were the valves?

How were the valves?

#99

Registered User

Thread Starter

The solution got a little bit darker, but not too bad. I just also adjusted valves today, still haven't taken it to the butt dyno yet! More to come

Edit: oh yeah forgot to mention, intake one was too tight and half of the other valves were too loose (I could get the next sized feeler gauge through). Started up well. To do the job I made some bent 14's with the oxyacetylene torch. The hardest part was getting the valve cover off (tight clearance)

Edit: oh yeah forgot to mention, intake one was too tight and half of the other valves were too loose (I could get the next sized feeler gauge through). Started up well. To do the job I made some bent 14's with the oxyacetylene torch. The hardest part was getting the valve cover off (tight clearance)

Last edited by jennygirl; 12-21-2015 at 04:37 PM.