Portion of Block behind Tcover....is gone... what to do?

#1

Portion of Block behind Tcover....is gone... what to do?

Many might know of me, and those who do have probably come near giving up on my motor, as it seems to be cursed! hahaha.

To the point;

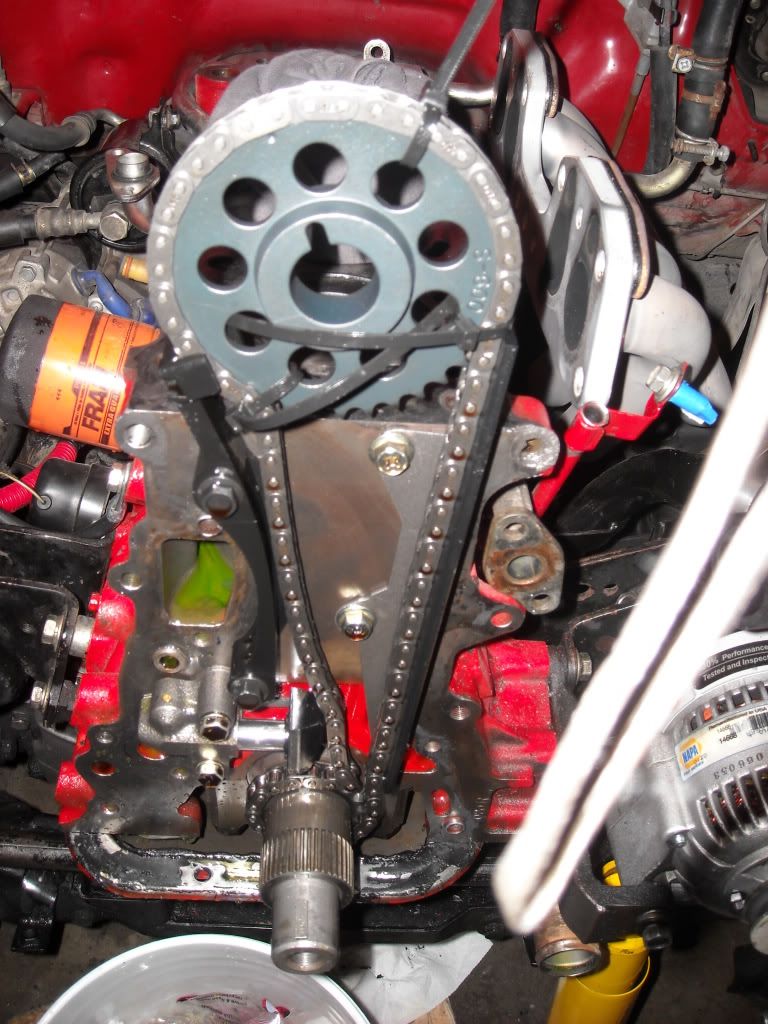

I just installed a new timing cover at 4500 miles due to leaking(engine builder/machinist's error.... ONE OF MANY!) I removed the head to have it checked out/rocker assembly checked out, and upon also removing the timing cover, I found this portion coming apart............

I've explained what I think happened in my build thread(in sig) below. So, for the purpose of this thread, and hoping for as many sets of '2 CENTS' as possible, I'll just ask;

IS THIS FIXABLE?

The portion you see in the first pic is now also missing that piece that looks like it's hanging on. It's now a clean chunk missing, no loose or 'hanging on' pieces. Can a welder stop by and patch that up? JB Weld? lol.

Thanks, very much, and to those who know me, .... VERY GRATEFUL for all the help and input over the last year as I've struggled with this NIGHTMARISH REBUILT 22RE! lol.

To the point;

I just installed a new timing cover at 4500 miles due to leaking(engine builder/machinist's error.... ONE OF MANY!) I removed the head to have it checked out/rocker assembly checked out, and upon also removing the timing cover, I found this portion coming apart............

I've explained what I think happened in my build thread(in sig) below. So, for the purpose of this thread, and hoping for as many sets of '2 CENTS' as possible, I'll just ask;

IS THIS FIXABLE?

The portion you see in the first pic is now also missing that piece that looks like it's hanging on. It's now a clean chunk missing, no loose or 'hanging on' pieces. Can a welder stop by and patch that up? JB Weld? lol.

Thanks, very much, and to those who know me, .... VERY GRATEFUL for all the help and input over the last year as I've struggled with this NIGHTMARISH REBUILT 22RE! lol.

#2

Registered User

I don't think it's fixable... other than probably a glob of jb weld (the quick dry stuff will probably be best as it has a thick consistency) then sanding it down to shape

the other method to seal this up is with a bunch of silicone... probably what I would do anyway

the other method to seal this up is with a bunch of silicone... probably what I would do anyway

#3

Registered User

hey chef, im no expert at welding , but pretty sure u cant weld cast iron .you would b better off 2 try jb weld , imo.

u r right , the man u can weld cast iron ! my bad , i just googled it , it gives u info on welding cast iron ! chef.

u r right , the man u can weld cast iron ! my bad , i just googled it , it gives u info on welding cast iron ! chef.

Last edited by waynesworld; 05-08-2011 at 12:20 PM.

#4

Registered User

cast iron can be welded, but very poorly... I've seen people weld cast iron exhaust manifolds... not pretty at all

but yeah, jb weld is probably the to go... if the remaining threads in that bolt hole are messed up, you'd want to helicoil/timecert it instead of just tapping it too... the insert will reinforce the jb weld part

but yeah, jb weld is probably the to go... if the remaining threads in that bolt hole are messed up, you'd want to helicoil/timecert it instead of just tapping it too... the insert will reinforce the jb weld part

#5

Thanks for the input, guys!

I, too, am starting to think that JB Kwik Weld might be the way to go. There are plenty of threads left in there(think you can see some of them) and they're in good shape. Only reason I was having trouble getting the bolts to thread in was,....well, as you can see, portions were dropping/kinking, and probably causing the bolt to repeatedly 'back up'. Eventually, it grabbed last time when I installed the new Tcover. But obviously, it's been 'fractured' for a bit.

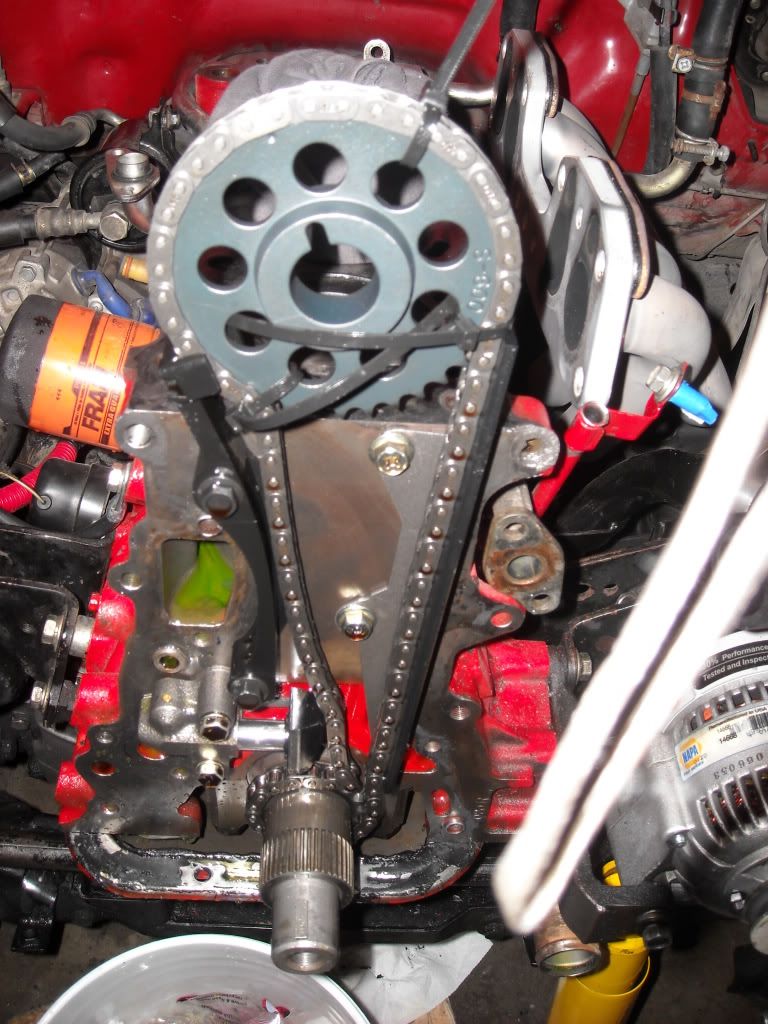

Any more input would be greatly appreciated. Here's another pic of EXACTLY where it is, in case it's too hard to tell for some.(You can see the top of the steel back timing guide/driver side)....

I, too, am starting to think that JB Kwik Weld might be the way to go. There are plenty of threads left in there(think you can see some of them) and they're in good shape. Only reason I was having trouble getting the bolts to thread in was,....well, as you can see, portions were dropping/kinking, and probably causing the bolt to repeatedly 'back up'. Eventually, it grabbed last time when I installed the new Tcover. But obviously, it's been 'fractured' for a bit.

Any more input would be greatly appreciated. Here's another pic of EXACTLY where it is, in case it's too hard to tell for some.(You can see the top of the steel back timing guide/driver side)....

#6

Registered User

yup... I pretty much had a good idea where it was from your first pic... seeing as the threads are all messed up, I'd definitely heilcoil it now! JB weld the hole first, then drill it out then put the heilcoil in... you want to have it all the way into the block itself, not just the JB welded part

oh yeah, I suggest you get rid of that fram oil filter if you care about your motor

oh yeah, I suggest you get rid of that fram oil filter if you care about your motor

#7

yup... I pretty much had a good idea where it was from your first pic... seeing as the threads are all messed up, I'd definitely heilcoil it now! JB weld the hole first, then drill it out then put the heilcoil in... you want to have it all the way into the block itself, not just the JB welded part

oh yeah, I suggest you get rid of that fram oil filter if you care about your motor

oh yeah, I suggest you get rid of that fram oil filter if you care about your motor

Trending Topics

#8

Registered User

Bummer chef. Let us know what you do for a fix. Good luck.

#10

Thanx, Jason!.... At this point, I'm really 'LEGITIMATELY CONCERNED' with EVERYTHING in this thing! lol. Actually, it ran fairly strong when not idling....but this darkened area around that hole looks just like the rest! lol. I'm sure that's normal, and looks just like many other hot rods I've done, etc., with 300K to 500K on them. Just NEVER HAD THIS HAPPEN, ever, to me! Neither have I heard of it! I'd be willing to try something, but just to have it not work and then tear it down again? I'm not sure man, ya know? I think I've dealt with PLENTY FOR A LIFETIME, ....no? lol.

Dealership. Sale Price was 4.80$ plus my 20% off. Bought 2, there was a limit at the time.

Dealership. Sale Price was 4.80$ plus my 20% off. Bought 2, there was a limit at the time.

#11

Registered User

cast iron can be welded, but very poorly... I've seen people weld cast iron exhaust manifolds... not pretty at all

but yeah, jb weld is probably the to go... if the remaining threads in that bolt hole are messed up, you'd want to helicoil/timecert it instead of just tapping it too... the insert will reinforce the jb weld part

but yeah, jb weld is probably the to go... if the remaining threads in that bolt hole are messed up, you'd want to helicoil/timecert it instead of just tapping it too... the insert will reinforce the jb weld part

#12

Well, ..... I got a response from Ted, who would love to comment on here, but I think it's just a 'slow dial up' thing that takes forever to sign in, etc.... so he just went to the pics on here, read up a bit and commented/responded, as such,>>>>>

"Hi.

This is Ted, Tod's Dad. I took a look at the pics, the block is history in my opinion. Sure it can be fixed but I would never trust it. The break is fresh so either a bad thread or something cross threaded would be my best guess.

The bores look OK, signs of some oil, not much. Odd, I don't think you reported any oil consumption or anything like that earlier, but...? Valve seals are rare on this design but if any guides are bad, seals don't last long.

I don't agree on the bronze guides comments, even if my kid does say so. He doesn't know anything, Dad is ALWAYS right!...*LOL**.. (I forgotted more than he ever knew...*sputter...)

That rusty bolt was put in that way I think. Probably still fine, buff it off unless the threads show any damage. Or buy a new set, they are inexpensive.

Ted"

Hahahaha.... I love reading his emails/threads/commentary! lol. I guess that's why I sig'd his statement, below, haha.

HOWEVER, I'm not happy to hear what he feels is 'just no doubt-NO GOOD'! lol. I'm also not happy to hear the oil consumption thing, either.

At this point, ...I suppose I might be best served AT LEAST replacing the block,.... maybe keeping the fairly new Pistons, etc. Just replace all the rings, etc, as I'd have to break in a new block, .....eh?

Thoughts would be appreciated, BIG TIME!

Mark

"Hi.

This is Ted, Tod's Dad. I took a look at the pics, the block is history in my opinion. Sure it can be fixed but I would never trust it. The break is fresh so either a bad thread or something cross threaded would be my best guess.

The bores look OK, signs of some oil, not much. Odd, I don't think you reported any oil consumption or anything like that earlier, but...? Valve seals are rare on this design but if any guides are bad, seals don't last long.

I don't agree on the bronze guides comments, even if my kid does say so. He doesn't know anything, Dad is ALWAYS right!...*LOL**.. (I forgotted more than he ever knew...*sputter...)

That rusty bolt was put in that way I think. Probably still fine, buff it off unless the threads show any damage. Or buy a new set, they are inexpensive.

Ted"

Hahahaha.... I love reading his emails/threads/commentary! lol. I guess that's why I sig'd his statement, below, haha.

HOWEVER, I'm not happy to hear what he feels is 'just no doubt-NO GOOD'! lol. I'm also not happy to hear the oil consumption thing, either.

At this point, ...I suppose I might be best served AT LEAST replacing the block,.... maybe keeping the fairly new Pistons, etc. Just replace all the rings, etc, as I'd have to break in a new block, .....eh?

Thoughts would be appreciated, BIG TIME!

Mark

#13

Registered User

well... if you're going to pull the motor out for a rebuild, you might as well replace the block... like you said, who knows what other nasty surprises await?

but oil consumption... that's always a tricky one... perhaps you should pour a little bit of seafoam on top of the pistons to free up those rings, slap the head back on and then see if it's better... if not, then new engine time

if I were you, I'd go the low budget route... this engine got screwed around with in the past, not worth trying to fix it more than you already need to

like I said, just jb weld the crap and helicoil the hole... it should hold well... just be sure to use silicone to seal it up good of course!

but oil consumption... that's always a tricky one... perhaps you should pour a little bit of seafoam on top of the pistons to free up those rings, slap the head back on and then see if it's better... if not, then new engine time

if I were you, I'd go the low budget route... this engine got screwed around with in the past, not worth trying to fix it more than you already need to

like I said, just jb weld the crap and helicoil the hole... it should hold well... just be sure to use silicone to seal it up good of course!

#14

Hey Mr. Man, ....

Yeah, not sure I had ANY consumption. I had NO smoking, at all, ...no seriously huge clean spots on the pistons after 4500 miles(but I did have some on the edges.... Tod, Ted's son seems to think that's most likely from the bad Guides allowing oil past, into the chamber, which is MOSTLY burned off with the gas....but that, while the gas is having to mix with the oil before being FIRED, ...it's most likely the cause for my 21MPG or so HWY and 15MPG City.... and that would, in turn, seeing as I drive almost ALL city..... 'cause some cleaning of the edges of pistons.

I know you've probably not got the time to read back through my build thread or troubleshooting thread, ..... But MAN, I'M TELLIN YA, I was VERY thorough on 'BREAK IN', then the later 'SWAPPED IN CAM BREAK IN', ....new adjusters, ..hell, I've basically torn this thing apart and put back together 3 times, minus the inner goodies. lol.

I've just been in an all out WAR with "Murphy" on this one, Man.... ya know?

Yeah, not sure I had ANY consumption. I had NO smoking, at all, ...no seriously huge clean spots on the pistons after 4500 miles(but I did have some on the edges.... Tod, Ted's son seems to think that's most likely from the bad Guides allowing oil past, into the chamber, which is MOSTLY burned off with the gas....but that, while the gas is having to mix with the oil before being FIRED, ...it's most likely the cause for my 21MPG or so HWY and 15MPG City.... and that would, in turn, seeing as I drive almost ALL city..... 'cause some cleaning of the edges of pistons.

I know you've probably not got the time to read back through my build thread or troubleshooting thread, ..... But MAN, I'M TELLIN YA, I was VERY thorough on 'BREAK IN', then the later 'SWAPPED IN CAM BREAK IN', ....new adjusters, ..hell, I've basically torn this thing apart and put back together 3 times, minus the inner goodies. lol.

I've just been in an all out WAR with "Murphy" on this one, Man.... ya know?

#15

Registered User

oh tell me about it... remember I asked a while ago about the ring & pinion? well it turns out *I* couldn't pull the axles out, then I took it to a shop I'm friends with and they couldn't pull the axles out... finally I took it to Baertrax and they couldn't do it either! They broke a 6000lbs puller!

It started out as a simple rebuild, then it snowballed from there... $900 labor, $300 for a nitro 4.10 gear set with shims, $300 for a whole axle assembly from the junk yard, $300 for bearings and other axle related parts, 30000 yen for the Altezza LSD unit.... *gasp* glad it just ended there! I went way over budget, and the costs went completely out of control.... now I just need a stupid $20 speedometer gear to "complete" this project

on the bright side, I'm now driving around with this bad boy:

it's a more tail happy now, more fun to drive, and best of all, handles better!

so yeah, I completely understand... I hate murphy!

sorry I don't have time to read your epic build thread, but what have you done to the head so far?

It started out as a simple rebuild, then it snowballed from there... $900 labor, $300 for a nitro 4.10 gear set with shims, $300 for a whole axle assembly from the junk yard, $300 for bearings and other axle related parts, 30000 yen for the Altezza LSD unit.... *gasp* glad it just ended there! I went way over budget, and the costs went completely out of control.... now I just need a stupid $20 speedometer gear to "complete" this project

on the bright side, I'm now driving around with this bad boy:

it's a more tail happy now, more fun to drive, and best of all, handles better!

so yeah, I completely understand... I hate murphy!

sorry I don't have time to read your epic build thread, but what have you done to the head so far?

Last edited by The MAN; 05-08-2011 at 09:12 PM.

#16

Registered User

chef, i would just jb weld it but what about adding a couple pieces of steel or something around the threaded area to help hold the jb weld on, and not just popping out after it has been in there for a little, where the black dots are put them or even if u go from one hole to another.

#17

cast iron can be welded, but very poorly... I've seen people weld cast iron exhaust manifolds... not pretty at all

but yeah, jb weld is probably the to go... if the remaining threads in that bolt hole are messed up, you'd want to helicoil/timecert it instead of just tapping it too... the insert will reinforce the jb weld part

but yeah, jb weld is probably the to go... if the remaining threads in that bolt hole are messed up, you'd want to helicoil/timecert it instead of just tapping it too... the insert will reinforce the jb weld part

#18

Registered User

good idea justin... perhaps a couple of pins or small screws around the bolt hole if there's enough room to put them in... it'll act as "rebars"

in any case, the surface will have to be sanded down afterwards

in any case, the surface will have to be sanded down afterwards

Thread

Thread Starter

Forum

Replies

Last Post