Fuel inside Vaucuum Hoses

#1

Ive been trying to figure out my engine troubles Ive been having since a HG rebuild (3vze 92 pickup 4x4). Ive rebuilt this same engine before so Im pretty intimate with this engine, and Ive tried almost everything. I would love a few experienced opinions though!

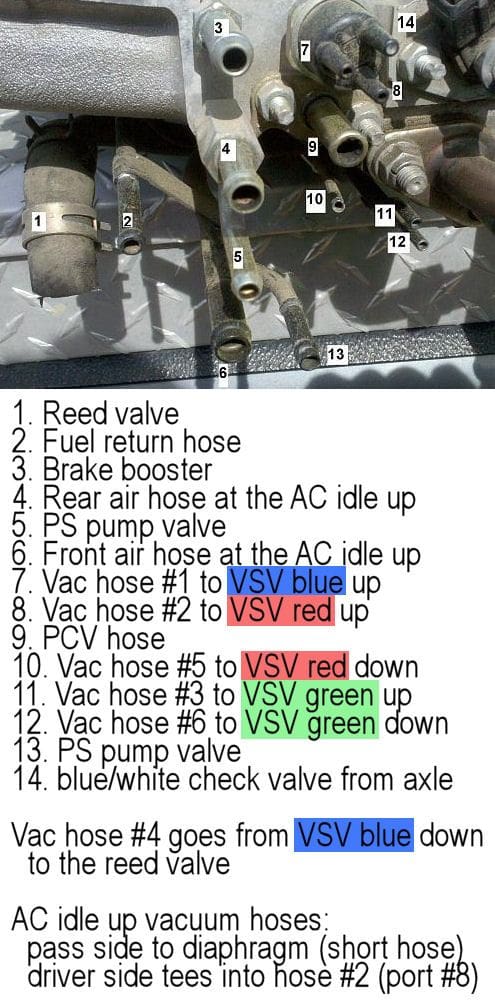

When I start it up it doesnt take much to get it firing, but it takes gas to keep it up and idling. Its sounds more like a semi-quiet harley than a v6 and the exhaust smells kinda like a lawnmower unfortunatley I hope im not burning oil.. And so I think half my cylinders dont wanna fire. It sounds healthy when i rev it to 4k+ Im holding throttle at about 2000 rpm to keep it from choking out, and it surges up with a 2k rpm variance prolly every 4 sec. when i let it run low rpm it make a "popping" noise in the plenum. It doesnt sounds like a "ping" to me but more like a very small backfire "pop" and you can feel it in the throttle body but not so much the plenum. Plugs have gasoline on them. A couple of the VSV vaccum lines had fuel dripping out of them when I unplugged them. WTF?

I have done:

All seal and gaskets

New oil pump

new valve seals

lapped valves

valve clearance in spec

new spark wires

new distributor

tried different ignition coil and ignitor from junkyard

tried new ECU from junkyard

checked all my vacuum lines for placement and leaks

new MAS

injectors are within spec electronic resistance all at 13.7 Ohms

My next move is to dump the oil for examination... shoulda prolly done that already. And then I am going to have to look into Fuel Pressure...Or do you think my injectors could be ruined even though they are in electronic spec? I also cleaned them all with brake cleaner, can you jam ˟˟˟˟ into the tip of the injector on accident? I think it would make sense if my fuel pressure was low what do you guys think?

When I start it up it doesnt take much to get it firing, but it takes gas to keep it up and idling. Its sounds more like a semi-quiet harley than a v6 and the exhaust smells kinda like a lawnmower unfortunatley I hope im not burning oil.. And so I think half my cylinders dont wanna fire. It sounds healthy when i rev it to 4k+ Im holding throttle at about 2000 rpm to keep it from choking out, and it surges up with a 2k rpm variance prolly every 4 sec. when i let it run low rpm it make a "popping" noise in the plenum. It doesnt sounds like a "ping" to me but more like a very small backfire "pop" and you can feel it in the throttle body but not so much the plenum. Plugs have gasoline on them. A couple of the VSV vaccum lines had fuel dripping out of them when I unplugged them. WTF?

I have done:

All seal and gaskets

New oil pump

new valve seals

lapped valves

valve clearance in spec

new spark wires

new distributor

tried different ignition coil and ignitor from junkyard

tried new ECU from junkyard

checked all my vacuum lines for placement and leaks

new MAS

injectors are within spec electronic resistance all at 13.7 Ohms

My next move is to dump the oil for examination... shoulda prolly done that already. And then I am going to have to look into Fuel Pressure...Or do you think my injectors could be ruined even though they are in electronic spec? I also cleaned them all with brake cleaner, can you jam ˟˟˟˟ into the tip of the injector on accident? I think it would make sense if my fuel pressure was low what do you guys think?

#2

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

First check that you have the fuel return line connected to the correct line. At least one in this forum accidentally connected it to a vacuum port, filling the plenum with fuel.

Your symptoms do suggest a stuck-open injector. An electrical test wouldn't diagnose that. Here's what I did:

https://www.yotatech.com/forums/f116.../#post52330847

(you do have to remove the plenum to do it, but at least you're not opening any fuel lines).

If you think you have some plugs not firing (plugs with gasoline sure suggests that), put your timing light inductive pickup on each plug wire and look for a flash. Then, pull each plug wire one at a time to see if that makes any difference.

Your symptoms do suggest a stuck-open injector. An electrical test wouldn't diagnose that. Here's what I did:

https://www.yotatech.com/forums/f116.../#post52330847

(you do have to remove the plenum to do it, but at least you're not opening any fuel lines).

If you think you have some plugs not firing (plugs with gasoline sure suggests that), put your timing light inductive pickup on each plug wire and look for a flash. Then, pull each plug wire one at a time to see if that makes any difference.

#5

So I did a fuel pressure test today. The pressure is pretty high around 52 psi. The spec in the fsm is 38 - 44 psi. So my fuel pressure regulator is out of spec it seems.

I also did what you referred me to Scope, and I used paper strips in intake manifold to see if my injectors were leaking, and 3/6 are in fact leaking! (I spilled a bit of fuel along the injector casing/isulators on one side so I might have to recheck that tomorrow.) I didnt have time to see how long the pressure dissapation is, as the rent-a-tool gauge was due back.

I cant find any threads about high fuel pressure issues, but 20% out of spec pressure seems significant right? Perhaps enough to ruin my injectors? I figured my HG melt ruined them

I also did what you referred me to Scope, and I used paper strips in intake manifold to see if my injectors were leaking, and 3/6 are in fact leaking! (I spilled a bit of fuel along the injector casing/isulators on one side so I might have to recheck that tomorrow.) I didnt have time to see how long the pressure dissapation is, as the rent-a-tool gauge was due back.

I cant find any threads about high fuel pressure issues, but 20% out of spec pressure seems significant right? Perhaps enough to ruin my injectors? I figured my HG melt ruined them

#6

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

That's way too high. If the vacuum diaphragm in the FPR somehow still worked, that would mean each cylinder would get 20% more fuel than the ECU was commanding. (The O2 sensor, once hot enough to work, would compensate some of that away, but it's really too far.)

More likely, the diaphragm is what failed, so as the engine vacuum changes, the rail would not track. Not good.

Since your next steps (removing the injectors, ...) are non-trivial, you could directly test the diaphragm with a hand vacuum pump. http://www.harborfreight.com/brake-b...kit-69328.html It should hold vacuum all day.

I'd re-run the injector leak test (I am very pleased to hear that the test actually works!), but I'll bet you get the same results. I doubt heat ruined them, probably just dirt and old age. You'll need to fix that, though. New injectors are north of $300, but I've seen re-mans for much, much less. https://www.amazon.com/AUS-Injection...XHY/ref=sr_1_3 You can have your own cleaned for even less https://www.amazon.com/AUS-Injection...XHY/ref=sr_1_3

More likely, the diaphragm is what failed, so as the engine vacuum changes, the rail would not track. Not good.

Since your next steps (removing the injectors, ...) are non-trivial, you could directly test the diaphragm with a hand vacuum pump. http://www.harborfreight.com/brake-b...kit-69328.html It should hold vacuum all day.

I'd re-run the injector leak test (I am very pleased to hear that the test actually works!), but I'll bet you get the same results. I doubt heat ruined them, probably just dirt and old age. You'll need to fix that, though. New injectors are north of $300, but I've seen re-mans for much, much less. https://www.amazon.com/AUS-Injection...XHY/ref=sr_1_3 You can have your own cleaned for even less https://www.amazon.com/AUS-Injection...XHY/ref=sr_1_3

#7

Update: Well I replaced the injectors and FPR out of a much younger truck, and have the same issues. Can you guys think of any other reasons that the fuel pressure would be so high? When I was performing the pressure test, I used a clear hose for the return line bypass and could see fuel moving, so I doubt the return line is clogged. I actually dont know if my pressure is high still, but the choppy idle/ dead cylinders are still an unfaultered issue.

Trending Topics

#8

Registered User

iTrader: (-1)

Update: Well I replaced the injectors and FPR out of a much younger truck, and have the same issues. Can you guys think of any other reasons that the fuel pressure would be so high? When I was performing the pressure test, I used a clear hose for the return line bypass and could see fuel moving, so I doubt the return line is clogged. I actually dont know if my pressure is high still, but the choppy idle/ dead cylinders are still an unfaultered issue.

The check valve inside the fuel pump should cause some restrictions to the flow (volume and pressure drop). if this is stuck wide open what is the effect at the fuel rail?

The relief valve inside the fuel pump should open between 45-55 psi. If this is stuck closed the only limit to flow to the rail is the pipe sizes?

Does the 92 use a pintle or hole type injector. Pintle injectors are more prone to corrosion and build up, more likely to leak with out regular cleaning.

Clogged or pinched lines between the regulator and fuel pump carrier. Which makes the regulator ineffective.

Faulty charcoal canister, or pinched clogged lines, increasing pressure differential of the rail and tank?

High pressure combined with failed injector screens allow small particles to erode the injector mechanical seal.

Faulty ECU switching to the alternate injection pattern earlier in the rpm range?

You can eyeball the fuel flow and tell the difference between 200 and 240 CC per minute?! (40/60)×6 = 4cc about the size of your little finger

˟

#9

Registered User

Did you verify that your fuel return hose is connected to the correct metal tube that runs under the plenum? That happens all the time after folks remove and reinstall all of those lines. I've seen it happen to at least a dozen people.

#10

You can eyeball the fuel flow and tell the difference between 200 and 240 CC per minute?! (40/60)×6 = 4cc about the size of your little finger

Does the 92 use a pintle or hole type injector. Pintle injectors are more prone to corrosion and build up, more likely to leak with out regular cleaning

Faulty ECU switching to the alternate injection pattern earlier in the rpm range?

Did you verify that your fuel return hose is connected to the correct metal tube that runs under the plenum? That happens all the time after folks remove and reinstall all of those lines. I've seen it happen to at least a dozen people.

Thanks for feedback

Last edited by coltonstewart; 01-19-2017 at 07:27 PM.

#11

Registered User

Hey, it's a chore to get all of those hoses routed back correctly. Just wanted to make sure you thought about that.

I'd say you have a bad pressure regulator or leaking injectors. I'd bet on the injectors because I, personally, have never seen a regulator allow high pressure. They normally allow too much fuel to return as apposed to the other way around.

As far as blowing in the return line, you're doing it all wrong. You need to blow in to the line coming off of the regulator while you have a buddy try and crank the truck. Just kidding. That test only benefits your buddy. Seriously, don't do that. You could blow some compressed air through that line if you think you may have a restriction. Not sure if you'll hear bubbles in the tank or not, but if you do then you either have cleared the restriction or never had one to begin with.

I'd say you have a bad pressure regulator or leaking injectors. I'd bet on the injectors because I, personally, have never seen a regulator allow high pressure. They normally allow too much fuel to return as apposed to the other way around.

As far as blowing in the return line, you're doing it all wrong. You need to blow in to the line coming off of the regulator while you have a buddy try and crank the truck. Just kidding. That test only benefits your buddy. Seriously, don't do that. You could blow some compressed air through that line if you think you may have a restriction. Not sure if you'll hear bubbles in the tank or not, but if you do then you either have cleared the restriction or never had one to begin with.

#12

I'd say you have a bad pressure regulator or leaking injectors. I'd bet on the injectors because I, personally, have never seen a regulator allow high pressure. They normally allow too much fuel to return as apposed to the other way around.

I have even checked my electrical lines from ECU to injectors, and from injectors to ignition coil (+). Ive also checked spark down to the plug, and I have just assumed that my brand new spec gapped NGK's are giving spark.

Last edited by coltonstewart; 01-19-2017 at 07:34 PM.

#13

Registered User

Unlikely coincidence. Is it possible that your CSI is running all the time? I know it's January and probably pretty cold where you are at but you can unplug it and see what happens. I know mine will start every time without it. I have seen where people have installed a toggle switch that controls the CSI. I never knew exactly why they did that but it just rang a bell. It may or may not be a long shot but it's easy to just unplug the electrical connector and see what happens, however if the CSI is leaking rather than running all the time, you're still going to have the same results. Do you know that it is not a leak on the CSI?

#14

Registered User

iTrader: (-1)

...

The relief valve inside the fuel pump should open between 45-55 psi. If this is stuck closed the only limit to flow to the rail is the pipe sizes?

...

...

Clogged or pinched lines between the regulator and fuel pump carrier. Which makes the regulator ineffective.

...

You can eyeball the fuel flow and tell the difference between 200 and 240 CC per minute?! (40/60)×6 = 4cc about the size of your little finger

˟

The relief valve inside the fuel pump should open between 45-55 psi. If this is stuck closed the only limit to flow to the rail is the pipe sizes?

...

...

Clogged or pinched lines between the regulator and fuel pump carrier. Which makes the regulator ineffective.

...

You can eyeball the fuel flow and tell the difference between 200 and 240 CC per minute?! (40/60)×6 = 4cc about the size of your little finger

˟

...

When I was doing the fuel pressure test I was actually seeing a return flow closer to half that around 100cc a minute or so. Today I went to blow into the return hose with my mouth, with and without the fuel (fill) cap on. It was a restricted flow considering I had to blow hard enough to get light headed and red-faced. But I dont know if theres some vacuum or mechanism that controls/ aids return flow? is 200 cc/min spec?

...

When I was doing the fuel pressure test I was actually seeing a return flow closer to half that around 100cc a minute or so. Today I went to blow into the return hose with my mouth, with and without the fuel (fill) cap on. It was a restricted flow considering I had to blow hard enough to get light headed and red-faced. But I dont know if theres some vacuum or mechanism that controls/ aids return flow? is 200 cc/min spec?

...

I don't know offhand if the return line is plumbed to "free air" or submerged. If it's submerged you would have to overcome the "head height" when applying manual pressure (blowing). With the return line disconnected at the tank it should flow pretty freely.

Inspect the lines for damage, and the tank for impact from below that might restrict flow. If not conclusive blow out the return line with an air gun and be prepared to catch any sludge/debris that comes out.

#15

Registered User

I say kill two birds with one stone. Plumb your fuel pressure tester back in, then put a longer line on the return off the pressure regulator and put it in a measuring container. To your return flow and rail pressure test at the same time. Get you some good clear data here and you can rule some things out. Also check your pressure while returning through the plumbing to the tank and compare it to the pressure you see when returning through your piece of hose to your measuring container. You will be able to accurately measure the resistance that is in your return to tank line.

#16

Registered User

iTrader: (-1)

I say kill two birds with one stone. Plumb your fuel pressure tester back in, then put a longer line on the return off the pressure regulator and put it in a measuring container. To your return flow and rail pressure test at the same time. Get you some good clear data here and you can rule some things out. Also check your pressure while returning through the plumbing to the tank and compare it to the pressure you see when returning through your piece of hose to your measuring container. You will be able to accurately measure the resistance that is in your return to tank line.

A.D.D. Got to me, or maybe it was lunch time. Totally forgot to suggest comparing pressure at both ends.