DIY headlight wiring harness upgrade for low $$

#1

Contributing Member

Thread Starter

I've seen this discussed a few times, but have still never seen a set-by-step write up, or even pictures of a full install

until now

don't hate me because it's a Jeep in the page the wiring is all the same, and this is REALLY good info, that I will be personally using here shortly when I install my new H4 conversion lights that I just got in

the wiring is all the same, and this is REALLY good info, that I will be personally using here shortly when I install my new H4 conversion lights that I just got in

http://www.go.jeep-xj.info/HowtoHeadlightLoom.htm

until now

don't hate me because it's a Jeep in the page

the wiring is all the same, and this is REALLY good info, that I will be personally using here shortly when I install my new H4 conversion lights that I just got in

the wiring is all the same, and this is REALLY good info, that I will be personally using here shortly when I install my new H4 conversion lights that I just got in

http://www.go.jeep-xj.info/HowtoHeadlightLoom.htm

#3

Registered User

Thats a good write up, i saved it for future use. I just got a 160 AMP alternator for my 4Runner, so along with that and this head light mod it should be a nice improvement.

#4

Registered User

Daniel Stern:

http://www.danielsternlighting.com/t...ys/relays.html

By the way, make sure to use SEALED relays! And if you're using relay connectors like you should (not just crimp on female spade connectors)- use RTV to seal the back side of the connector. Then put dielectric grease in the connector for a 100% waterproof setup. I've never had a relay fail on me, even with one mounted in the back of the truck on the frame through northeast winters with lots of road salt.

Also, now would be a good time to upgrade your crappy stock headlight connector to a ceramic connector, and use 14awg wire. If you're tricky like me, you can add a simple diode in the wiring for dual beams. (dual beams = low beam stays on with highs, but high beams turn off with lows, a very easy modification. )

)

http://www.danielsternlighting.com/t...ys/relays.html

By the way, make sure to use SEALED relays! And if you're using relay connectors like you should (not just crimp on female spade connectors)- use RTV to seal the back side of the connector. Then put dielectric grease in the connector for a 100% waterproof setup. I've never had a relay fail on me, even with one mounted in the back of the truck on the frame through northeast winters with lots of road salt.

Also, now would be a good time to upgrade your crappy stock headlight connector to a ceramic connector, and use 14awg wire. If you're tricky like me, you can add a simple diode in the wiring for dual beams. (dual beams = low beam stays on with highs, but high beams turn off with lows, a very easy modification.

)

)

Last edited by shaeff; 01-14-2010 at 06:07 AM.

#5

Contributing Member

Thread Starter

diode from the high beam output at the relay to the low beam signal input at the relay

because also with doing this, I'm also going to run the relay signal input of my driving lights to the output of the low beams, so the driving lights will be on with both the low and high beams

Last edited by iamsuperbleeder; 01-14-2010 at 03:24 PM.

#7

Registered User

not that tricky, and I already have plans on doing so

diode from the high beam output at the relay to the low beam signal input at the relay

because also with doing this, I'm also going to run the relay signal input of my driving lights to the output of the low beams, so the driving lights will be on with both the low and high beams

diode from the high beam output at the relay to the low beam signal input at the relay

because also with doing this, I'm also going to run the relay signal input of my driving lights to the output of the low beams, so the driving lights will be on with both the low and high beams

Glad to see (no pun intended) that someone else is doing it! The extra light is fantastic!

Glad to see (no pun intended) that someone else is doing it! The extra light is fantastic!Edit: I just read over that link you posted, - get relay harnesses. Don't use spade connectors on the relays. Do as I said above, and you'll NEVER have a problem. With spade connectors, you get corrosion quite easily.

Last edited by shaeff; 01-15-2010 at 10:06 PM.

Trending Topics

#8

Registered User

Join Date: Dec 2009

Location: Austin, TX

Posts: 268

Likes: 0

Received 0 Likes

on

0 Posts

Doesn't a diode mean a voltage drop? That means less voltage to the lamps, and need for a high-wattage resistor that can dissipate some heat. Try disconnecting your highs, and flip between high and low, see if the lows are a bit dimmer when the high beams are on.

There must be a way to rewire if you want the lows always on; just hook the lows up before the relay and leave the highs as they are. Or maybe I'm missing something....

There must be a way to rewire if you want the lows always on; just hook the lows up before the relay and leave the highs as they are. Or maybe I'm missing something....

#9

Contributing Member

Thread Starter

Doesn't a diode mean a voltage drop? That means less voltage to the lamps, and need for a high-wattage resistor that can dissipate some heat. Try disconnecting your highs, and flip between high and low, see if the lows are a bit dimmer when the high beams are on.

There must be a way to rewire if you want the lows always on; just hook the lows up before the relay and leave the highs as they are. Or maybe I'm missing something....

There must be a way to rewire if you want the lows always on; just hook the lows up before the relay and leave the highs as they are. Or maybe I'm missing something....

a diode allows power to only flow in one direction

Think about it like this. Wiring in a resister would be like taking a 3" exhaust, cutting it in half, and welding in a section of 1" pipe... all it's going to do is restrict the flow. But, wiring in a diode would be like putting a flapper-tip on the end of the exhaust. It's like a one-way valve, and is only going to let the flow go in one direction

Last edited by iamsuperbleeder; 01-16-2010 at 12:26 PM.

#10

Registered User

Doesn't a diode mean a voltage drop? That means less voltage to the lamps, and need for a high-wattage resistor that can dissipate some heat. Try disconnecting your highs, and flip between high and low, see if the lows are a bit dimmer when the high beams are on.

There must be a way to rewire if you want the lows always on; just hook the lows up before the relay and leave the highs as they are. Or maybe I'm missing something....

There must be a way to rewire if you want the lows always on; just hook the lows up before the relay and leave the highs as they are. Or maybe I'm missing something....

If you were to put that diode directly from the high beam to the low, you'd burn it (and likely some of your wiring) up in a flash. They can carry high voltage, but not a lot of amperage.

Cliffnotes: you can only use the diode to trip the relays, NOT the actual lights. Let the relays take the current!

#11

Registered User

Join Date: Dec 2009

Location: Austin, TX

Posts: 268

Likes: 0

Received 0 Likes

on

0 Posts

Shaeff, that makes a lot more sense. I'd like to see a diagram.

Super Bleeder, thanks for the description. Your analogy works well for describing diode forward voltage drop. The flap takes a small amount of force for the exhaust to push and hold open. The voltage drop is typically about 0.7V, which is about 6% in our 12V systems. Read more here:

http://www.kpsec.freeuk.com/components/diode.htm

This doesn't matter if the diode isn't going inline with the light bulb, for a relay it's no problem.

I don't know how the circuits are wired, but here's what I was thinking:

Super Bleeder, thanks for the description. Your analogy works well for describing diode forward voltage drop. The flap takes a small amount of force for the exhaust to push and hold open. The voltage drop is typically about 0.7V, which is about 6% in our 12V systems. Read more here:

http://www.kpsec.freeuk.com/components/diode.htm

This doesn't matter if the diode isn't going inline with the light bulb, for a relay it's no problem.

I don't know how the circuits are wired, but here's what I was thinking:

#12

Contributing Member

Thread Starter

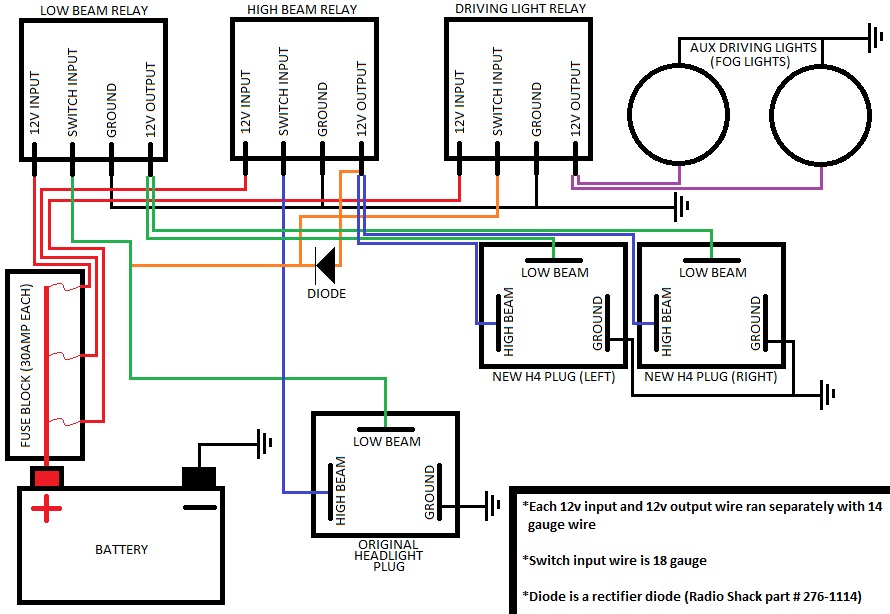

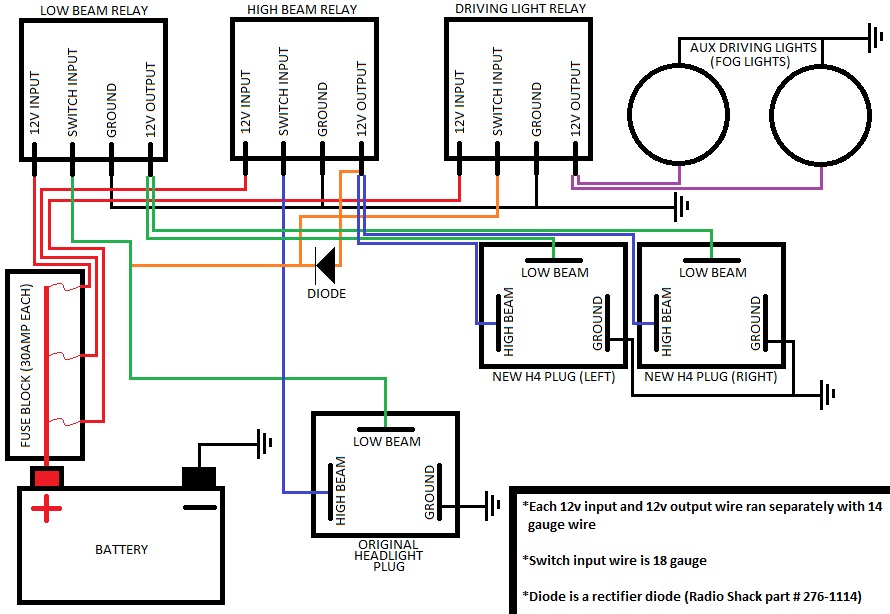

Schematics are fun to make

I picked up all of the supplies today minus the relays that I already had (cost about $40 for the supplies, but I ended up doubling that cost by getting a new soldering gun, and some other little things, lol), and will probably get started on the harness tomorrow, since the truck's broke down anyway due to the alternator going out

Soldering and heat shrinking all the connections too

I picked up all of the supplies today minus the relays that I already had (cost about $40 for the supplies, but I ended up doubling that cost by getting a new soldering gun, and some other little things, lol), and will probably get started on the harness tomorrow, since the truck's broke down anyway due to the alternator going out

Soldering and heat shrinking all the connections too

Last edited by iamsuperbleeder; 01-16-2010 at 01:49 PM.

#13

Registered User

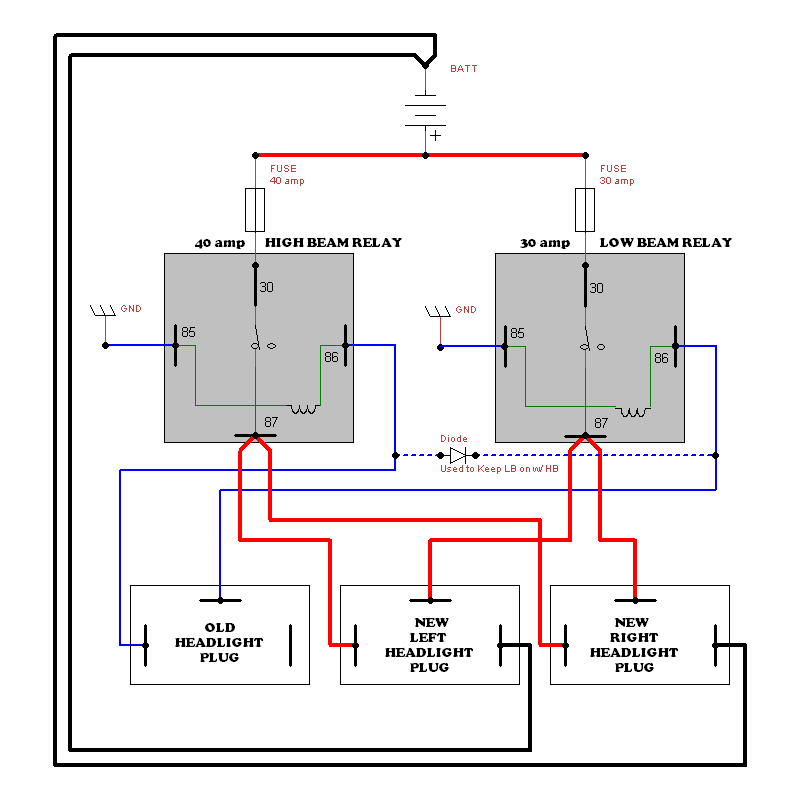

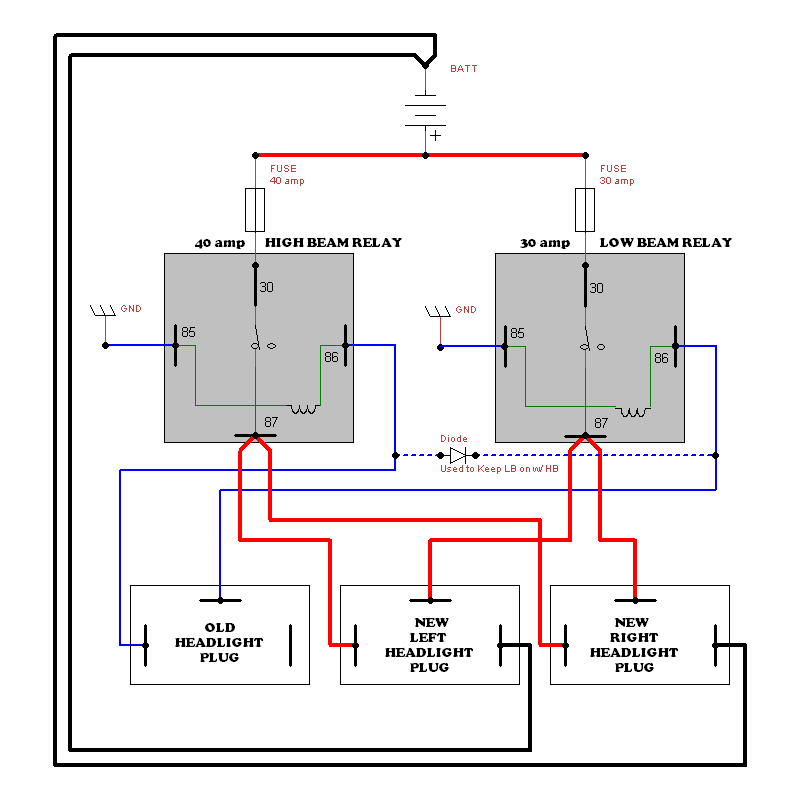

Dammit Superbleeder you beat me to it, anyway mines nicer. lol. I hope this is right, someone please correct me if I am reading the tutorial wrong and let me know what I need to fix in the schematic. Anyway here we go. Basically the tutorial is using the factory headlight sockets to power the new relays which in turn operate the new sockets. I have added a dotted line with a diode which I believe is the right way to keep the low beams on with the high beams. Hope this helps someone.

Last edited by xxxtreme22r; 01-16-2010 at 02:16 PM.

#14

Contributing Member

Thread Starter

that's basically the same setup, only I'm adding on a set of driving/fog lights that kick on with the headlights too

and I'm also installing some Hella 500FF's on the tube bumper on an independantly operated cuircut

and I'm also installing some Hella 500FF's on the tube bumper on an independantly operated cuircut

#15

Registered User

Years ago I was going to make my own but after I priced the sealed high quality relays and after I seen how expensive they were at the time I just bought the kit. I bought it from Northwest Offroad. It is actually the Painless Wiring kit here: http://www.painlesswiring.com/webcat...=4x4%20OffRoad

I did not pay that price. I think it was roughly $60 but I cannot remember. High quality wire and relays were used. I believe they are either Hella relays or Bosch.

James

I did not pay that price. I think it was roughly $60 but I cannot remember. High quality wire and relays were used. I believe they are either Hella relays or Bosch.

James

#16

Contributing Member

Thread Starter

well I've already got a set of good 40amp relays that I got from work for free, so that was a discount for me there

plus, I've always enjoyed the puzzles of wiring

plus, I've always enjoyed the puzzles of wiring

Last edited by iamsuperbleeder; 01-17-2010 at 04:08 PM.

#17

Contributing Member

Join Date: Mar 2003

Location: COTKU,Ontario,Canada

Posts: 11,334

Likes: 0

Received 0 Likes

on

0 Posts

Looks good guys but why use woosie 14AWG (only one size up from the 16AWG in stock sys.)? Step up to a more manly 12AWG or even 10AWG (if your chest is hairy enough  ). Yes the wire will be heavier and may be a little stiffer but the resistance will be even lower and you'll be able to go to some seriously high lamp wattages with it.

). Yes the wire will be heavier and may be a little stiffer but the resistance will be even lower and you'll be able to go to some seriously high lamp wattages with it.

). Yes the wire will be heavier and may be a little stiffer but the resistance will be even lower and you'll be able to go to some seriously high lamp wattages with it.

). Yes the wire will be heavier and may be a little stiffer but the resistance will be even lower and you'll be able to go to some seriously high lamp wattages with it.

#18

Registered User

Although you will see an improvement over the old wiring with 14awg, 12awg is a better choice. 10awg isn't enough of an improvement over 12 to warrant the extra cost and weight, IMO. Check out the Daniel Stern link I posted earlier in the thread.

And use heat shrink that oozes adhesive if you want it truly waterproof.

And use heat shrink that oozes adhesive if you want it truly waterproof.

#19

Registered User

Join Date: Jul 2008

Location: Grew up in S.C.V, So Cal.....now in Hampstead, NC

Posts: 4,592

Likes: 0

Received 0 Likes

on

0 Posts

'Bleederdude, please do your own write up, with pic for each stage, and write it up, say for some1 who doesn't know or really understand wire....like me! I've wanted to something very similar, but using Hella 550's....

#20

Contributing Member

Thread Starter

too late freak

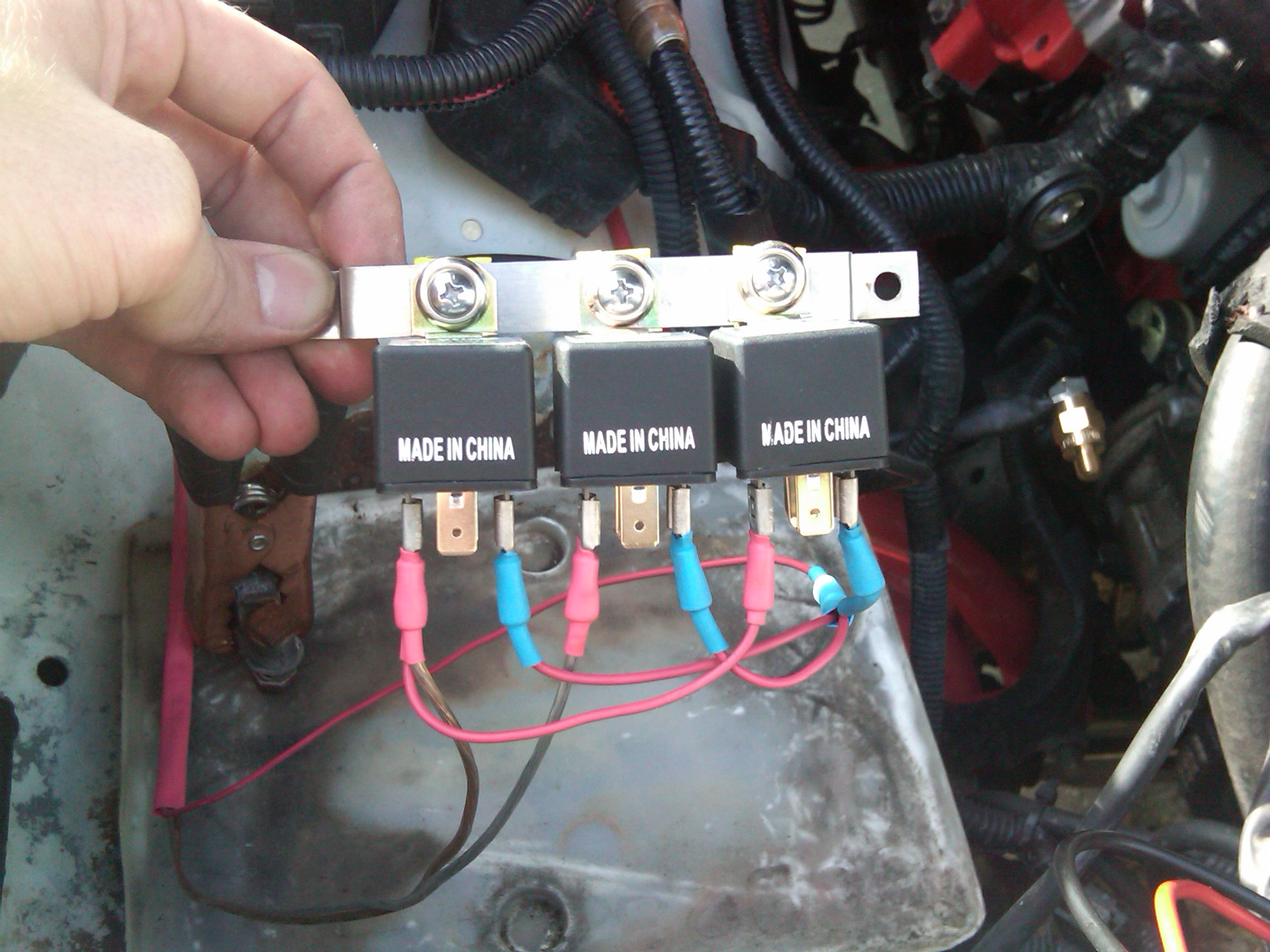

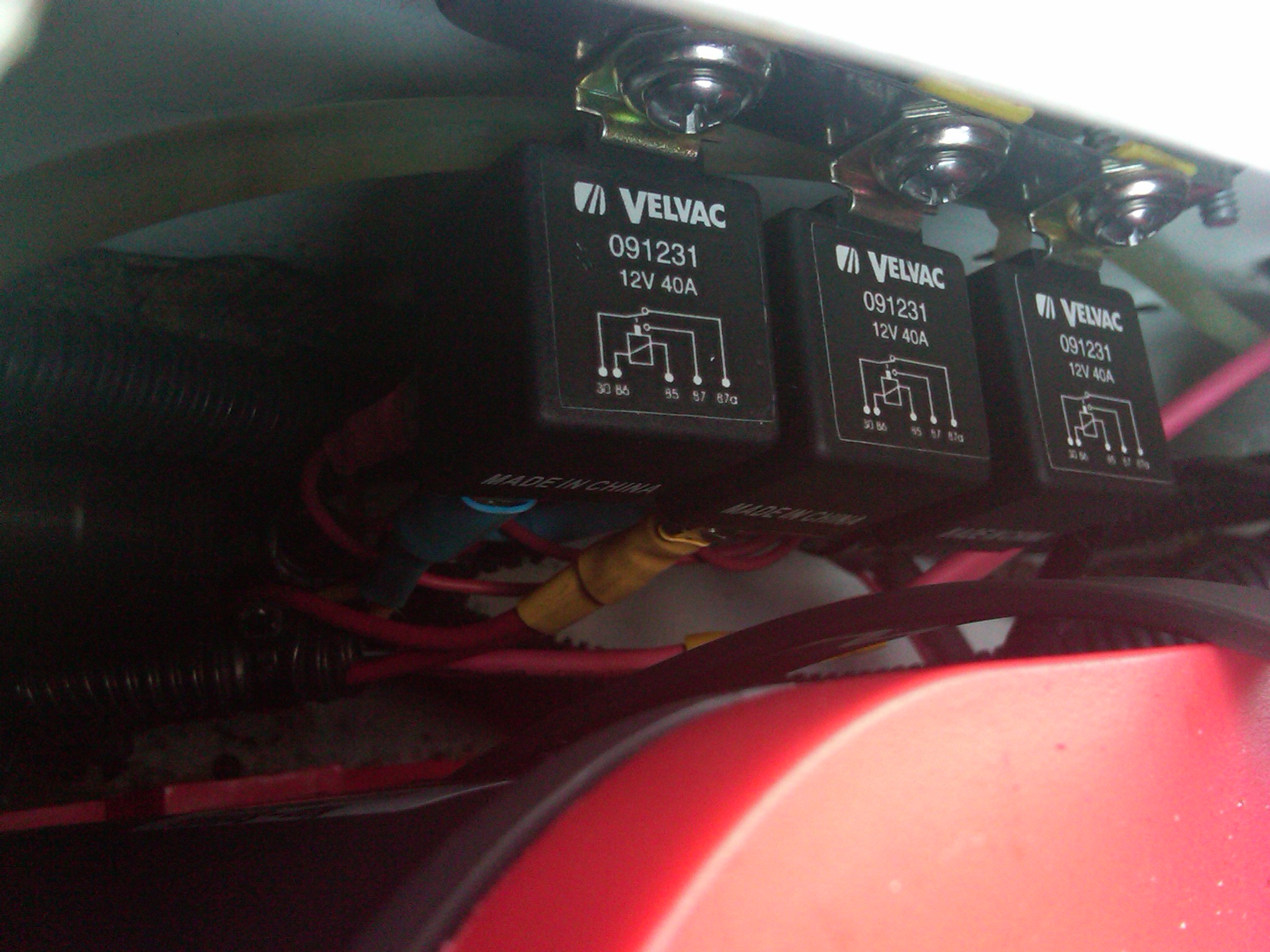

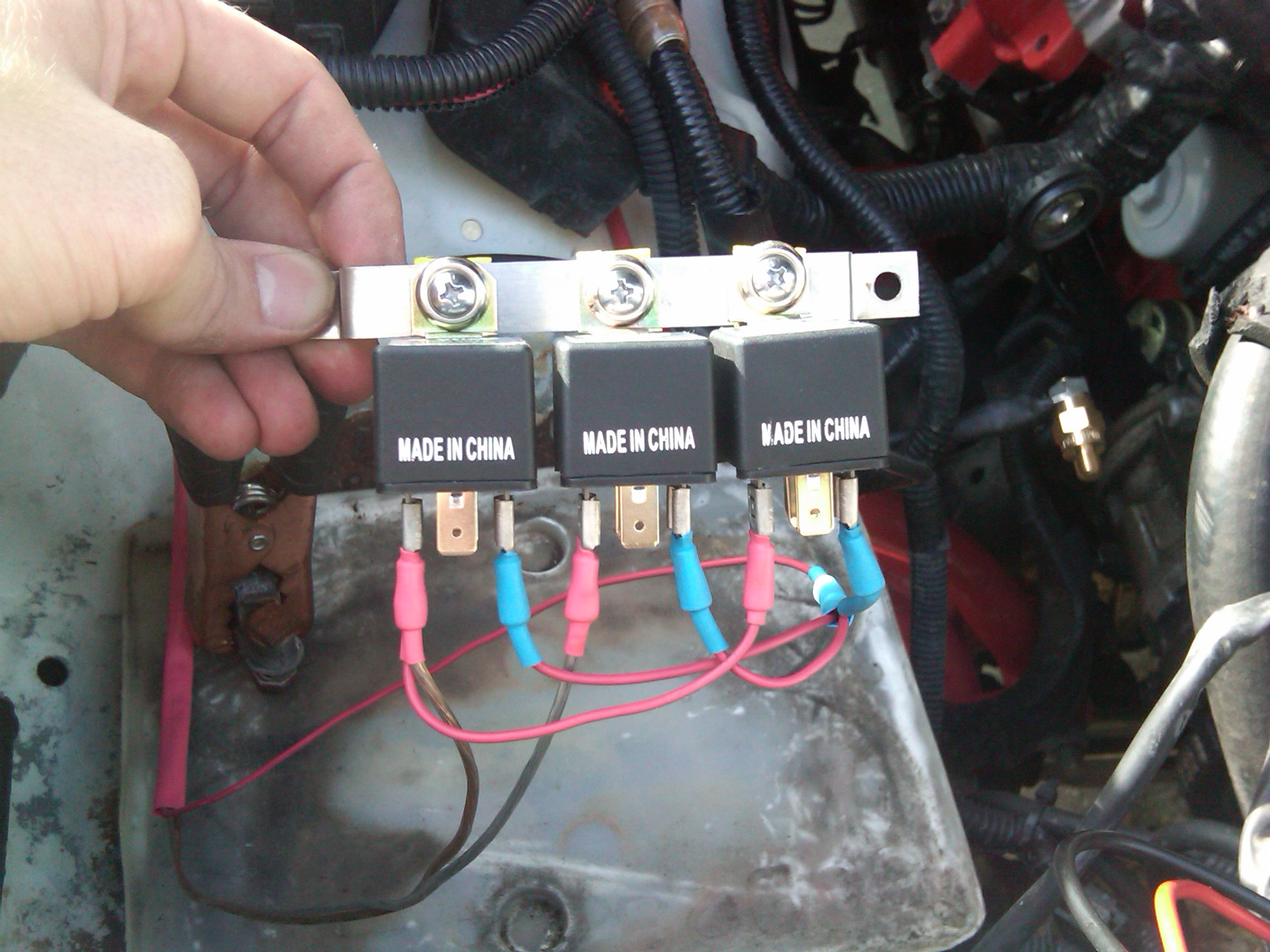

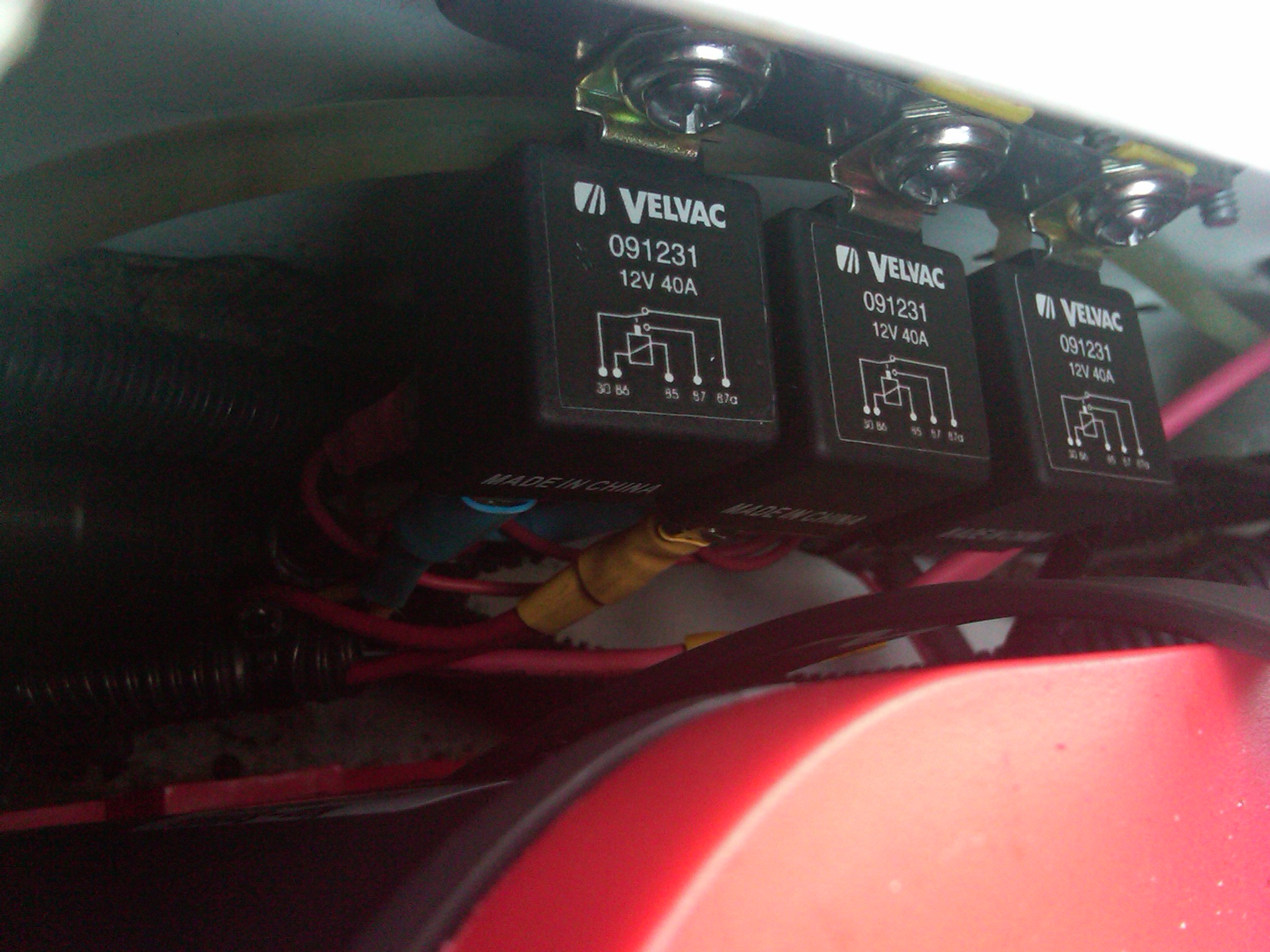

fabbed a relay mounting bracket out of a large hose clamp; worked like a charm

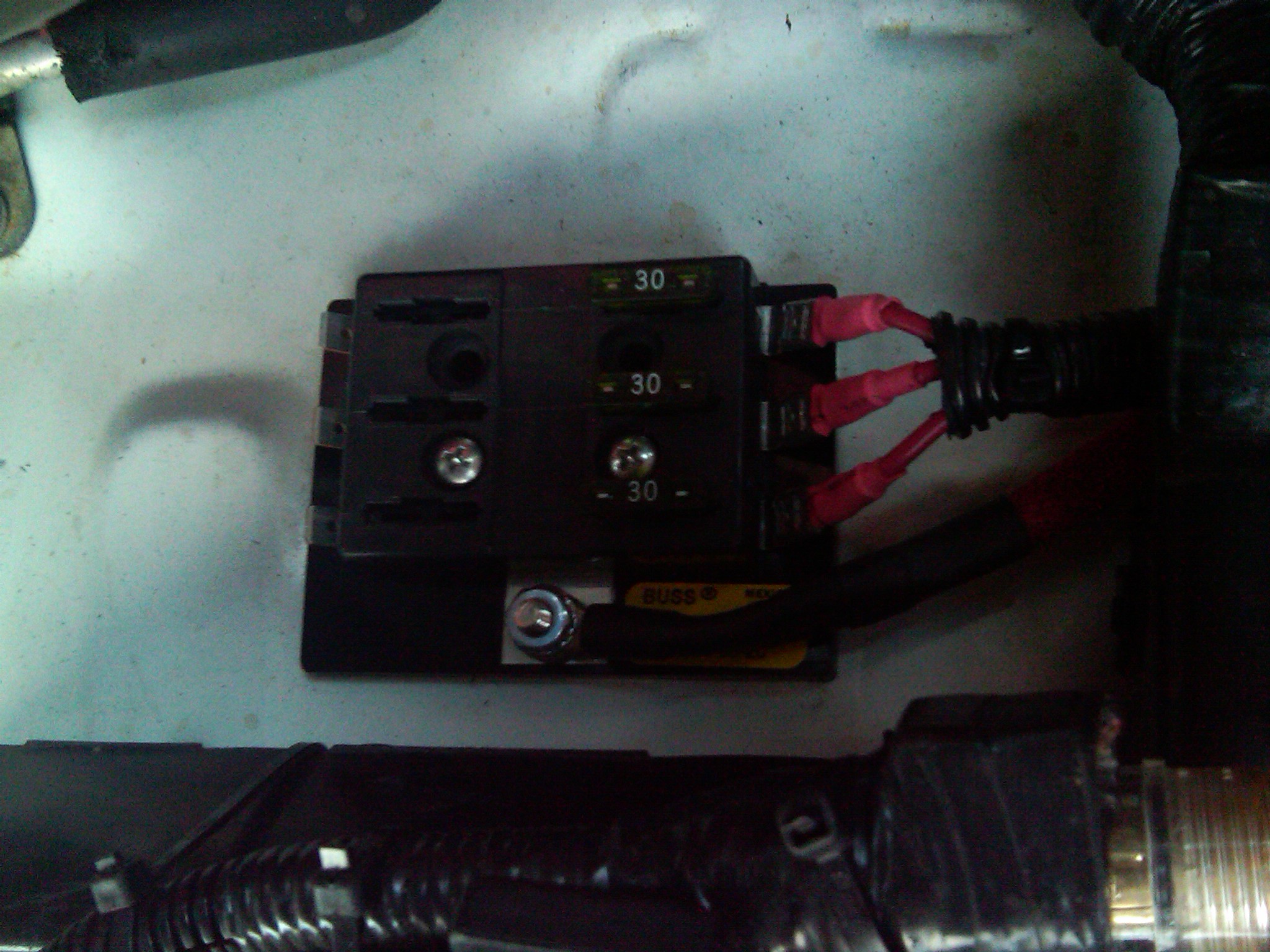

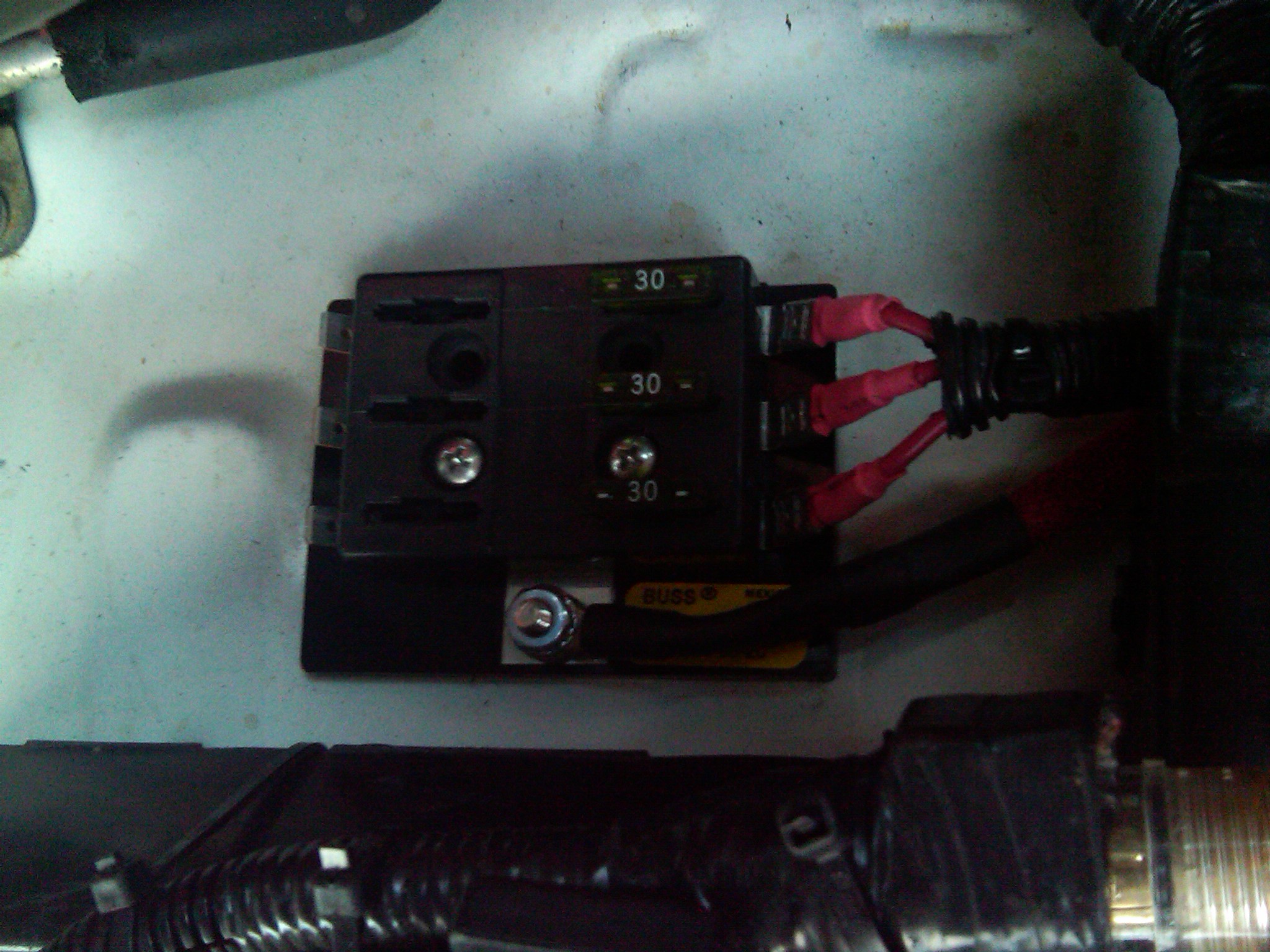

mounted the fuse block

ran the wires from the fuse block, and from the original headlight socket, with the diode in bewteen the two leads from the original plug

and found a suitable place to mount the realy assembly, right on the inner fender behind the battery

ran the new headlight plug wires, then dropped the battery in to make sure there was plenty of room still

threw some fuses in the fuse block

and everything works right!

although I don't have any other pics on the process... I was kinda in a hurry as I was loosing light...

and I realise I didn't use actual relay sockets wire in; I just used the spade connectors. I've used them just like this in the past wirh no problems; if I do get corrosion issues, I've got plenty of extra wire to cut the spades off and hard-wire in some sockets instead

fabbed a relay mounting bracket out of a large hose clamp; worked like a charm

mounted the fuse block

ran the wires from the fuse block, and from the original headlight socket, with the diode in bewteen the two leads from the original plug

and found a suitable place to mount the realy assembly, right on the inner fender behind the battery

ran the new headlight plug wires, then dropped the battery in to make sure there was plenty of room still

threw some fuses in the fuse block

and everything works right!

although I don't have any other pics on the process... I was kinda in a hurry as I was loosing light...

and I realise I didn't use actual relay sockets wire in; I just used the spade connectors. I've used them just like this in the past wirh no problems; if I do get corrosion issues, I've got plenty of extra wire to cut the spades off and hard-wire in some sockets instead

Last edited by iamsuperbleeder; 01-17-2010 at 04:23 PM.