CODE 52, Knock sensor gurus please read.

#1

Registered User

Thread Starter

CODE 52, Knock sensor gurus please read.

First off Im not drunk LOL, 2nd .. I am no stranger to Code 52.

Ive fixed many knock sensor issues, on many 3.0 V6's over the past 15 years as a mechanic, but Ive run into the ultimate code 52.

1989 4runner, 1st Gen body style, 3.0 V6 Automatic 4x4

Just rebuilt the Top end of the V6, replaced the knock sensor wire while I had the heads off, (I always do ). Fired up the Truck, sounds good, runs good.

No check engine light.

Going through all my checks before I take it to smog (California BS) and I noticed my Timing was like 22' btdc, and realized my TPS was bad. I pulled off the throttle body to remove the TPS easier cause the bolt heads were stripped. Swapped the TPS, bolted the Throttle body back up, fired it up, set timing to 10' BTDC with in Diagnostic mode. Went to drive it, CHECK ENGINE LIGHT comes on...code 52

Years of this I know Code 52 is caused by only 3 things.

1)Knock sensor 9% probability

2)wiring 90% probability

3)computer 1% Probabiltiy

I figured I must of bent or moved the knock sensor plug working on the throttle body,(as 90% of Code 52 is the old frailed wiring) unplugged the KS connecter, straightened it. Reattached it. Still code 52.

I have a knock sensor I saved, that I know is good, for my testing, its drilled and tapped to the Engine lift hanger, with a new tail plug on it, I bolted it up, unplugged the main KS connector, and connected it up the by pass.....Still code 52

So I figured my wiring is bad. So I got a co axle wire (tv cables work great)

I ran a new wire, from the main KS wire connector, under the throttle body, to the pin location on the Computer. I cut the wire , connected the new co axle wire, grounded the shielding cover wire, only on this end, to the computer ground, where the computer bolts up. Fired it up...STILL CODE 52!!

I then pulled the wire from the main connector, hooked it up to my by pass knock sensor....STILL CODE 52...

Before I swap computers is there anything I missing??? Its been a while since I ran a whole new wire, I only ground it at the computer end right?? Code 52 is a sumbitch.

Ive fixed many knock sensor issues, on many 3.0 V6's over the past 15 years as a mechanic, but Ive run into the ultimate code 52.

1989 4runner, 1st Gen body style, 3.0 V6 Automatic 4x4

Just rebuilt the Top end of the V6, replaced the knock sensor wire while I had the heads off, (I always do ). Fired up the Truck, sounds good, runs good.

No check engine light.

Going through all my checks before I take it to smog (California BS) and I noticed my Timing was like 22' btdc, and realized my TPS was bad. I pulled off the throttle body to remove the TPS easier cause the bolt heads were stripped. Swapped the TPS, bolted the Throttle body back up, fired it up, set timing to 10' BTDC with in Diagnostic mode. Went to drive it, CHECK ENGINE LIGHT comes on...code 52

Years of this I know Code 52 is caused by only 3 things.

1)Knock sensor 9% probability

2)wiring 90% probability

3)computer 1% Probabiltiy

I figured I must of bent or moved the knock sensor plug working on the throttle body,(as 90% of Code 52 is the old frailed wiring) unplugged the KS connecter, straightened it. Reattached it. Still code 52.

I have a knock sensor I saved, that I know is good, for my testing, its drilled and tapped to the Engine lift hanger, with a new tail plug on it, I bolted it up, unplugged the main KS connector, and connected it up the by pass.....Still code 52

So I figured my wiring is bad. So I got a co axle wire (tv cables work great)

I ran a new wire, from the main KS wire connector, under the throttle body, to the pin location on the Computer. I cut the wire , connected the new co axle wire, grounded the shielding cover wire, only on this end, to the computer ground, where the computer bolts up. Fired it up...STILL CODE 52!!

I then pulled the wire from the main connector, hooked it up to my by pass knock sensor....STILL CODE 52...

Before I swap computers is there anything I missing??? Its been a while since I ran a whole new wire, I only ground it at the computer end right?? Code 52 is a sumbitch.

Last edited by some drunk guy; 09-18-2015 at 03:27 PM.

The following users liked this post:

Catchinup2speed (10-29-2020)

#2

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

Dang, SDG, you do know a lot about knock sensors.

All I can add is that user AZSpeed claims that he got rid of his Code 52 only by replacing all the capacitors in his ECU (you may be able to find his post using his username). Obviously, not ALL of the capacitors affect the knock sensor, but I sure don't know which one does.

There are certainly those who disagree, but I don't believe mounting a knock sensor to the lifting hook would do any good at all. If it did, why would Toyota bother to "hide" it? But it sounds like you've tested all around that too.

Good luck, and let us know what you find.

All I can add is that user AZSpeed claims that he got rid of his Code 52 only by replacing all the capacitors in his ECU (you may be able to find his post using his username). Obviously, not ALL of the capacitors affect the knock sensor, but I sure don't know which one does.

There are certainly those who disagree, but I don't believe mounting a knock sensor to the lifting hook would do any good at all. If it did, why would Toyota bother to "hide" it? But it sounds like you've tested all around that too.

Good luck, and let us know what you find.

#3

Registered User

how is the pin in the ecu plug? i use spare new pins to test connector pin wear in plugs, but you can substitute with something of same size, often paperclip or pin. how are the grounds? engine to body, engine to battery, battery to body, ecu to body. how's the voltage going to the sensor? how is it plugged in? should be fairly constant like 5v steady and 2.5v plugged in.

#4

Registered User

Join Date: Jul 2012

Location: Northern Colorado

Posts: 1,776

Likes: 0

Received 109 Likes

on

81 Posts

As I read your post, SDG, I don't think you're done testing things thoroughly. You've made a great start, and done exactly what I would have done up to this point. You've done the relatively easy stuff first, which is a great approach. Here's where I see you are right now.

- Replaced the wiring from ECU to plug. Check

- Tested with a known good sensor in a questionable location. (engine hanger - jury is still out on whether this location works reliably). Failure is inconclusive.

- Tested with an unknown (original) sensor and pigtail in a known good location. Failure is also inclusive.

Unless I missed something, you haven't tested a known good sensor with a known good pigtail in a known good location. Unfortunately going further means removing the plenum, but that might be in your future.

It might be easier to first follow up on the capacitor idea if you're comfortable with a soldering iron (sounds like you might be). I think that's what I would pursue next. I'd much rather do some soldering than pull the plenum.

- Replaced the wiring from ECU to plug. Check

- Tested with a known good sensor in a questionable location. (engine hanger - jury is still out on whether this location works reliably). Failure is inconclusive.

- Tested with an unknown (original) sensor and pigtail in a known good location. Failure is also inclusive.

Unless I missed something, you haven't tested a known good sensor with a known good pigtail in a known good location. Unfortunately going further means removing the plenum, but that might be in your future.

It might be easier to first follow up on the capacitor idea if you're comfortable with a soldering iron (sounds like you might be). I think that's what I would pursue next. I'd much rather do some soldering than pull the plenum.

#6

Registered User

Thread Starter

Update: fixed!

So after reading many many posts, people kept mentioning The Tps sensor and distributor could be culprits in causing " noise" that may interfer with factory signal. Hard for me to believe as its kinda seperate signals to ecm but...

So today I did 2 things, what exactly fixed it I don't know... For sure, but I re set my new TPS, as it was slightly out of adjustment, I also eliminated my new tail plug I had put on my knock sensor on the engine hanger, and I connected my new co axle cable end directly onto my known good knock sensor ( on the engine lift hanger)

No more code 52!!

And just to clarify..

Code 52 is Not caused by an engine that make have a loud knock, the check engine light comes on only when the computer does not read a signal from the sensor

So today I did 2 things, what exactly fixed it I don't know... For sure, but I re set my new TPS, as it was slightly out of adjustment, I also eliminated my new tail plug I had put on my knock sensor on the engine hanger, and I connected my new co axle cable end directly onto my known good knock sensor ( on the engine lift hanger)

No more code 52!!

And just to clarify..

Code 52 is Not caused by an engine that make have a loud knock, the check engine light comes on only when the computer does not read a signal from the sensor

The following users liked this post:

Catchinup2speed (10-29-2020)

#7

Code 52 knock sensor 89 4Runner 3.0 V6

First off Im not drunk LOL, 2nd .. I am no stranger to Code 52.

Ive fixed many knock sensor issues, on many 3.0 V6's over the past 15 years as a mechanic, but Ive run into the ultimate code 52.

1989 4runner, 1st Gen body style, 3.0 V6 Automatic 4x4

Just rebuilt the Top end of the V6, replaced the knock sensor wire while I had the heads off, (I always do ). Fired up the Truck, sounds good, runs good.

No check engine light.

Going through all my checks before I take it to smog (California BS) and I noticed my Timing was like 22' btdc, and realized my TPS was bad. I pulled off the throttle body to remove the TPS easier cause the bolt heads were stripped. Swapped the TPS, bolted the Throttle body back up, fired it up, set timing to 10' BTDC with in Diagnostic mode. Went to drive it, CHECK ENGINE LIGHT comes on...code 52

Years of this I know Code 52 is caused by only 3 things.

1)Knock sensor 9% probability

2)wiring 90% probability

3)computer 1% Probabiltiy

I figured I must of bent or moved the knock sensor plug working on the throttle body,(as 90% of Code 52 is the old frailed wiring) unplugged the KS connecter, straightened it. Reattached it. Still code 52.

I have a knock sensor I saved, that I know is good, for my testing, its drilled and tapped to the Engine lift hanger, with a new tail plug on it, I bolted it up, unplugged the main KS connector, and connected it up the by pass.....Still code 52

So I figured my wiring is bad. So I got a co axle wire (tv cables work great)

I ran a new wire, from the main KS wire connector, under the throttle body, to the pin location on the Computer. I cut the wire , connected the new co axle wire, grounded the shielding cover wire, only on this end, to the computer ground, where the computer bolts up. Fired it up...STILL CODE 52!!

I then pulled the wire from the main connector, hooked it up to my by pass knock sensor....STILL CODE 52...

Before I swap computers is there anything I missing??? Its been a while since I ran a whole new wire, I only ground it at the computer end right?? Code 52 is a sumbitch.

Ive fixed many knock sensor issues, on many 3.0 V6's over the past 15 years as a mechanic, but Ive run into the ultimate code 52.

1989 4runner, 1st Gen body style, 3.0 V6 Automatic 4x4

Just rebuilt the Top end of the V6, replaced the knock sensor wire while I had the heads off, (I always do ). Fired up the Truck, sounds good, runs good.

No check engine light.

Going through all my checks before I take it to smog (California BS) and I noticed my Timing was like 22' btdc, and realized my TPS was bad. I pulled off the throttle body to remove the TPS easier cause the bolt heads were stripped. Swapped the TPS, bolted the Throttle body back up, fired it up, set timing to 10' BTDC with in Diagnostic mode. Went to drive it, CHECK ENGINE LIGHT comes on...code 52

Years of this I know Code 52 is caused by only 3 things.

1)Knock sensor 9% probability

2)wiring 90% probability

3)computer 1% Probabiltiy

I figured I must of bent or moved the knock sensor plug working on the throttle body,(as 90% of Code 52 is the old frailed wiring) unplugged the KS connecter, straightened it. Reattached it. Still code 52.

I have a knock sensor I saved, that I know is good, for my testing, its drilled and tapped to the Engine lift hanger, with a new tail plug on it, I bolted it up, unplugged the main KS connector, and connected it up the by pass.....Still code 52

So I figured my wiring is bad. So I got a co axle wire (tv cables work great)

I ran a new wire, from the main KS wire connector, under the throttle body, to the pin location on the Computer. I cut the wire , connected the new co axle wire, grounded the shielding cover wire, only on this end, to the computer ground, where the computer bolts up. Fired it up...STILL CODE 52!!

I then pulled the wire from the main connector, hooked it up to my by pass knock sensor....STILL CODE 52...

Before I swap computers is there anything I missing??? Its been a while since I ran a whole new wire, I only ground it at the computer end right?? Code 52 is a sumbitch.

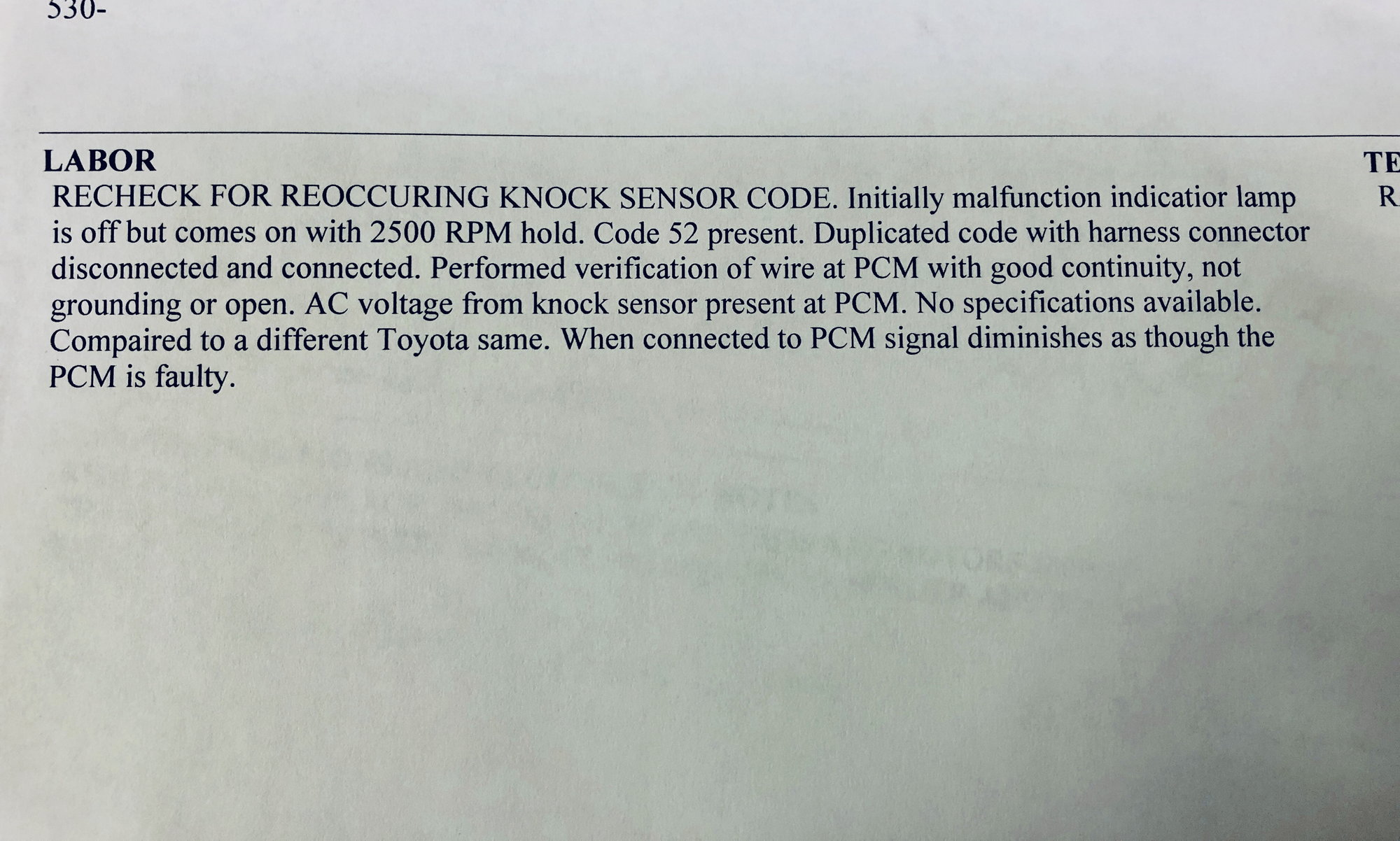

Replaced motor with rebuilt engine after head gasket issue. Started engine got up to 1600rpm cel come on with code 52 knock sensor. Took it to a technician found out #4 injector issue. Tech moved the wire around and reconnected the connection to the injector and in doing that wiggled the short harness for the knock sensor and the cel went off. Bought all new injectors, knock sensor, and short harness. And now the code 52 is back. Took it back to the tech and checked and verified signal to the ECM. Not sure where to go from here. I’ve purchased a used ECM and just waiting to check and see if it fixes the issue. Any advice would be great.

Trending Topics

#8

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

Very, very unlikely to be the ECM. But if it fixes it, hey, there's always a first time.

Last edited by scope103; 03-03-2019 at 11:39 AM.

#9

Thank you it was

What does that tell you? That wire (often called the knock sensor "pigtail') is in a hellish environment and often goes bad. The knock signal is a very low level signal, and crappy shielding or insulation will keep the ECM from "hearing" the signal. Replace it. About $12 at the (a) dealer. https://parts.lakelandtoyota.com/p/_...221935010.html (You'll have to remove the lower intake manifold to do it.)

Very, very unlikely to be the ECM. But if it fixes it, hey, there's always a first time.

Very, very unlikely to be the ECM. But if it fixes it, hey, there's always a first time.

Any other ideas?

#10

Do you know how they checked the signal all the way back to the ECM? If they just verified continuity from the pigtail back to the ECM pin, that wouldn’t be enough and it would take the knock sensor out of the troubleshooting loop. New knock sensors can be defective.

#12

You may want to list the specifics on what exact vehicle you’re dealing with. Did I miss that? I wouldn’t want to assume, since it is at a mechanic, but voltage to the ECM, ECU, PCM, whatever you want to call it, doesn’t guarantee the correct signal is being seen by the computer. If previously manipulating the wiring got rid of the code, I’d focus on that.

#14

You’re probably looking at running a new shielded wire all the way back to the ECM as a next step. There’s plenty of threads on it here. My wiring in my ‘88 was in terrible shape, even the section that was buried in the main harness.

#15

Registered User

To add more curious fuel to the fire, I had a 95 doing the same thing; Code 52. Then life happened and 3 years later I just finished a 3.4 swap on it, and I'm still getting a knock sensor code P0330. And I can confirm everything regarding wiring and continuity is good. So we're left with what are the things in common that could possibly throw a knock code that doesn't have to do with the engine, the ECM, or the wiring since all of that is new/different. The ground point for the engine? Of course, it could be entirely a coincidence, but it sure is spooky. [solved this one, the plug to the ECM on the harness side was barely loose, so I pulled it out and put it back in and the code disappeared. I don't quite remember when I posted this, but the custom wiring harness I bought for the swap had also wired the knock sensor harness plug wrong. So there were 2 wiring issues to be solved]

Last edited by wonkainc; 02-09-2021 at 10:49 AM.

#16

YT Community Team

Interesting observation a tech made during the 3vze headgasket recall when we had literally a dozen engines apart on any given day. If the repair required the knock sensor to be unplugged for any significant amount of time( like the block being decked) if it was left unplugged from the harness until reassembly it almost always set a code 52.

The tech found if he took the knock sensor and plugged it into the harness and just let it hang there till reassembly it would work fine and not set codes. It became moot a few months into the recall when Toyota approved a new Knock sensor with the recall. But still, interesting observation. So if my tech’s theory is correct, a used “good” sensor sitting around may not be all that good.

The tech found if he took the knock sensor and plugged it into the harness and just let it hang there till reassembly it would work fine and not set codes. It became moot a few months into the recall when Toyota approved a new Knock sensor with the recall. But still, interesting observation. So if my tech’s theory is correct, a used “good” sensor sitting around may not be all that good.

#17

Registered User

Code 52

Vehicle manufacturers, in order to comply with draconian (my opinion) U.S. (read Ca.) and European emission standards, are backed into the proverbial corner.

The useable RPM range, and fuel quality, that modern internal combustion engines are designed to run on, and still meet ALL criteria, is basically what caused the birth of the knock sensor.

The knock they are looking for isn't audible at all during the engines RPM range, rather, the onset of "ping vibrations" caused by the fuel charge being combusted at the wrong time in the engines cycle.

In the old days, my father called it "spark knock", and it was very audible then.

You could have solved that problem back then, by running a couple of tankfuls of "Ethyl" at $.35.9 a gallon through the old Dodge, or by pulling the head off (1/2 hour task) and doing a carbon and valve job.

The modern knock sensor looks for the beginnings of "spark knock" as high order vibrations(ringing) in the block during the combustion cycle. That is the reason it is buried so deeply in the V of the casting.

You can actually hear a version of the vibration in the distinctive clatter of a 35 year old diesel passenger car engine. "It's a diesel though", so who cared.

Now, all the posts on this forum deal with making the code 52 "go away", but maybe the code is real, and the sensor is doing its job.

Maybe the engine architecture has been altered in some way during a rebuild, so as to bring on these vibrations during normal running.

Just sayin....

Art.

The useable RPM range, and fuel quality, that modern internal combustion engines are designed to run on, and still meet ALL criteria, is basically what caused the birth of the knock sensor.

The knock they are looking for isn't audible at all during the engines RPM range, rather, the onset of "ping vibrations" caused by the fuel charge being combusted at the wrong time in the engines cycle.

In the old days, my father called it "spark knock", and it was very audible then.

You could have solved that problem back then, by running a couple of tankfuls of "Ethyl" at $.35.9 a gallon through the old Dodge, or by pulling the head off (1/2 hour task) and doing a carbon and valve job.

The modern knock sensor looks for the beginnings of "spark knock" as high order vibrations(ringing) in the block during the combustion cycle. That is the reason it is buried so deeply in the V of the casting.

You can actually hear a version of the vibration in the distinctive clatter of a 35 year old diesel passenger car engine. "It's a diesel though", so who cared.

Now, all the posts on this forum deal with making the code 52 "go away", but maybe the code is real, and the sensor is doing its job.

Maybe the engine architecture has been altered in some way during a rebuild, so as to bring on these vibrations during normal running.

Just sayin....

Art.

#18

Registered User

Is a knock sensor something I can work on? I have a 1989 Toyota P/U that has Code 52. Can I get a shielded cable to replace it or just take it to Toyota to fix if not ungodly cost prohibitive?

#19

YT Community Team

Some are easy to do, others, not so much.

#20

Registered User

Buy Toyota OEM, not an Autozone aftermarket, and get a new Toyota OEM wiring harness. Parts all together should be like 200 for the knock sensor and 25 or something for the wiring harness.

I have a 3.4L and a knock sensor job was $1000. 600 in labor and 400 in parts. I then had to redo the job trying to solve a wiring harness problem and got into some serious headaches regarding circuit continuity, but the whole tear it apart and put it back together adventure took me about 5 hours.

Hope that helps.