86 Runner Injectors Not Firing - Help

#21

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

If all goes well, I plan on pulling the entire harness out of my 85 tomorrow. I will take some pics as I do, If you think your harness is in to bad of a shape, you might look at replacing the bad part. You wouldnt need to pull the harness out of the dash. The injector harness uplugs from the computer and routes thru the firewall. I think that one is going to be okay for you.

If I am remembering right, the one that you are having problems with is the one that either connects to the fusebox or the one that you would need to remove the inner fender and it connects to the computer. Either way, both of them arent to bad to replace if you can find a good one and if you need to replace that particular section of the harness, if it is the one I am thinking of. Check that section of bad wire further upstream and down stream from what you mentioned would be my suggestion.

Right now the carbon isnt really causing you a lot of problems from my experience but from what you did mention, the plenum is also going to be full of carbon and most of the hose connections that attach to the plenum are going to be plugged as well.

While the plenum is off and if you want to clean it, remove the Throttle Body but do NOT mess with the TPS, leave it attached to the Throttle Body and I take my Plenum to the carwash and spray it out real well. There are several other ways to clean it, it is just how I do mine.

When I post, I try to suggest to the orginal poster about a problem but try to add in general to others that may see what you found and what to be aware of. Kind of like the two birds with one stone saying if you know what I mean. Sounds like you are on the downhill side and a little more time and you will have it running again soon. Great job finding it.

If I am remembering right, the one that you are having problems with is the one that either connects to the fusebox or the one that you would need to remove the inner fender and it connects to the computer. Either way, both of them arent to bad to replace if you can find a good one and if you need to replace that particular section of the harness, if it is the one I am thinking of. Check that section of bad wire further upstream and down stream from what you mentioned would be my suggestion.

Right now the carbon isnt really causing you a lot of problems from my experience but from what you did mention, the plenum is also going to be full of carbon and most of the hose connections that attach to the plenum are going to be plugged as well.

While the plenum is off and if you want to clean it, remove the Throttle Body but do NOT mess with the TPS, leave it attached to the Throttle Body and I take my Plenum to the carwash and spray it out real well. There are several other ways to clean it, it is just how I do mine.

When I post, I try to suggest to the orginal poster about a problem but try to add in general to others that may see what you found and what to be aware of. Kind of like the two birds with one stone saying if you know what I mean. Sounds like you are on the downhill side and a little more time and you will have it running again soon. Great job finding it.

Last edited by Terrys87; 09-27-2013 at 06:13 AM.

#23

Registered User

Thread Starter

Join Date: Aug 2013

Location: Houston, TX

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

***Update: Last night I pulled the upper plenum back off and exposed wiring. With the exception of the larger black wire (that I mentioned previously), everything looked fine. I cut\spliced\soldered everything in question and covered with corrosion block.

Once back together, I cranked the truck and it ran fine for about 60 seconds then died. I re-cranked several times (CSI unplugged) and couldn't get it to run longer than 30 sec.

I guess I'm not quite back to square one, but it's definitely not resolved.

[B]Here are my thoughts after sleeping on it:[B]

-Simulation of airflow generates fuel (i.e. manually moving AFM needle with throttle makes truck run). This leads me to believe vacuum leak, but I'm fairly confident this has been exhausted. Also, while doing this "trick" with the intake housing pulled out of the air box, I can cup my hand over the boot and feel suction. The truck also dies shortly after doing this as it should.

-Is it likely that the injector resistor is testing properly but dropping resistance with a load on it? I tried bypassing this last night and temporarily jumping 12V directly to the blue\yellow wires. This didn't make a difference but I don't know if that's a good test.

... I hate to admit this but I'm really wishing I was running a carb right now.

Once back together, I cranked the truck and it ran fine for about 60 seconds then died. I re-cranked several times (CSI unplugged) and couldn't get it to run longer than 30 sec.

I guess I'm not quite back to square one, but it's definitely not resolved.

[B]Here are my thoughts after sleeping on it:[B]

-Simulation of airflow generates fuel (i.e. manually moving AFM needle with throttle makes truck run). This leads me to believe vacuum leak, but I'm fairly confident this has been exhausted. Also, while doing this "trick" with the intake housing pulled out of the air box, I can cup my hand over the boot and feel suction. The truck also dies shortly after doing this as it should.

-Is it likely that the injector resistor is testing properly but dropping resistance with a load on it? I tried bypassing this last night and temporarily jumping 12V directly to the blue\yellow wires. This didn't make a difference but I don't know if that's a good test.

... I hate to admit this but I'm really wishing I was running a carb right now.

#24

Registered User

Thread Starter

Join Date: Aug 2013

Location: Houston, TX

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

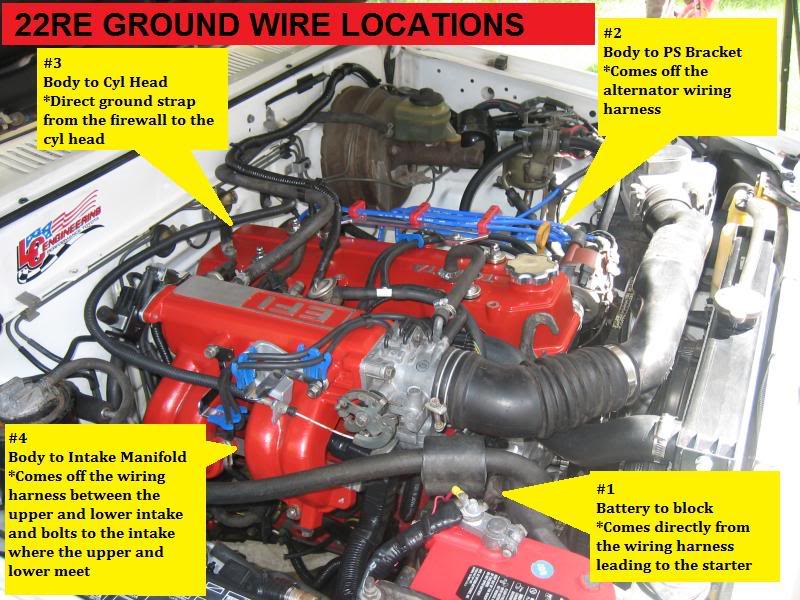

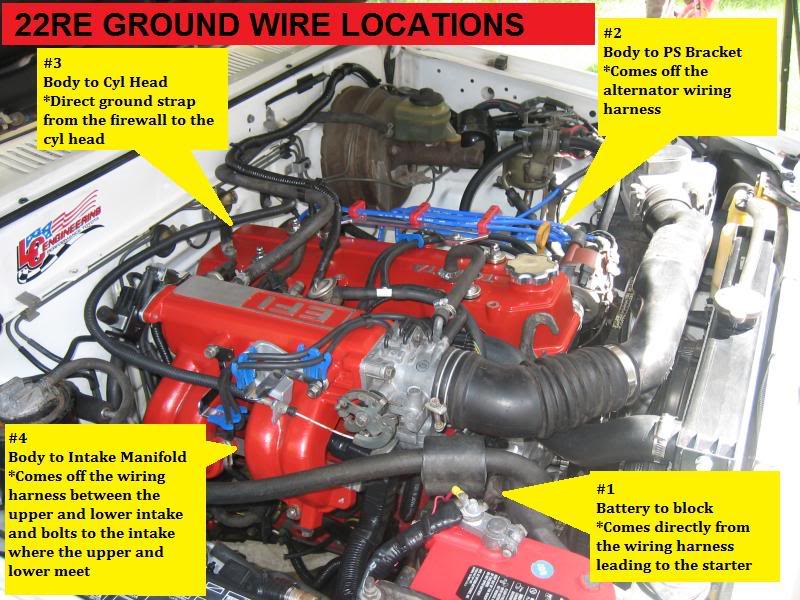

Does anyone happen to know the locations of all the ground wires to the ECM? Not the main battery grounds to the truck, rather the actual ground wires connecting directly to the ECM (i.e. E01, E02, E1). Also, I still have code 7 which the FSM suggest is a bad O2 sensor. Is it possible this is causing the truck to shut down?

#25

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

There is a ground wire by the fuse box on the drivers kick panel and the one that is on the manifold is the main one for the injectors in the pic below as I understand it. I am sure there is more grounds but these are the main ones.

#26

Registered User

Thread Starter

Join Date: Aug 2013

Location: Houston, TX

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

I was able to spend quite a bit of time on the runner this weekend and here are my findings:

-Noid light verified that wiring fixed injector problem

-Truck still dies after 30 sec

-CLAMPING FUEL RETURN LINE makes the truck run great. I believe this tells me that I'm losing pressure for some reason, or does it? I tried replacing the obvious, FP regulator and it didn't fix the problem. I've read that part typically doesn't fail so I find it unlikely that I it failed on me and I received a bad new unit as well.

On another note, I rented a FP gauge from Autozone and used the banjo bolt attachment. I couldn't get it to seal and the slightest bit of torque sheared the bolt. I'm going to search around town today and try to find a good gauge.

Here are the two possibilities that I'm thinking:

1. There is possibly something else inline on the return side that I'm missing that helps hold pressure. I looked at the diagram in the FSM and the only thing I can't locate on the truck is the "fuel pulsation damper". Does anyone know where this is and if it would potentially cause this problem?

2. Extra fuel pressure is compensating for something else. Here's the hypothetical: say that I building the rail to 50 PSI with the line clamped; therefore, each time the injectors open they are releasing more fuel that they are supposed to. This would (I think) compensate for a vacuum leak that I'm not able to find, but here's why I have a hard time with that: With the line clamped, I can drive the truck at any rpm and it runs great. I can adjust the idle and it's very responsive and consistent. I can't help but feel like the "stars would need to align" for this "compensation theory" to actually be accurate.

At the end of the day, I need to find a gauge that works and it will let me know if I'm losing too much pressure. If this is the case then what is next? Would you guys' try replacing the pressure regulator again or is there another part that I'm missing?

Thanks again to everyone for all the help.

-Noid light verified that wiring fixed injector problem

-Truck still dies after 30 sec

-CLAMPING FUEL RETURN LINE makes the truck run great. I believe this tells me that I'm losing pressure for some reason, or does it? I tried replacing the obvious, FP regulator and it didn't fix the problem. I've read that part typically doesn't fail so I find it unlikely that I it failed on me and I received a bad new unit as well.

On another note, I rented a FP gauge from Autozone and used the banjo bolt attachment. I couldn't get it to seal and the slightest bit of torque sheared the bolt. I'm going to search around town today and try to find a good gauge.

Here are the two possibilities that I'm thinking:

1. There is possibly something else inline on the return side that I'm missing that helps hold pressure. I looked at the diagram in the FSM and the only thing I can't locate on the truck is the "fuel pulsation damper". Does anyone know where this is and if it would potentially cause this problem?

2. Extra fuel pressure is compensating for something else. Here's the hypothetical: say that I building the rail to 50 PSI with the line clamped; therefore, each time the injectors open they are releasing more fuel that they are supposed to. This would (I think) compensate for a vacuum leak that I'm not able to find, but here's why I have a hard time with that: With the line clamped, I can drive the truck at any rpm and it runs great. I can adjust the idle and it's very responsive and consistent. I can't help but feel like the "stars would need to align" for this "compensation theory" to actually be accurate.

At the end of the day, I need to find a gauge that works and it will let me know if I'm losing too much pressure. If this is the case then what is next? Would you guys' try replacing the pressure regulator again or is there another part that I'm missing?

Thanks again to everyone for all the help.

Last edited by huffman102833; 09-30-2013 at 07:28 AM.

#27

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

First, the fuel pressure damper is on the pressure side. If it fails (mine did), it leaks fuel. You would have smelled that. It has nothing, really, to do with overall pressure.

The banjo bolts require new (one-time-use) crush washers. If you just used the ones that happened to be with the gauge, I'm not surprised it leaked. If you didn't use washers at all .... (use a torque wrench; the spec torque is only 25 ftlbs; if you sheared a bolt you had to be way over that).

As you figured out, the most likely thing happening when you clamp the fuel return line is that you raise the rail pressure and are putting in too much fuel open-loop. My first guess is that all of time working on the truck with injectors not opening enough is that you moved the learned air-fuel setting all the way to rich. I believe that removing the EFI fuse will re-set the learned A/F; you'll need to drive it for a while to re-learn the correct setting.

The banjo bolts require new (one-time-use) crush washers. If you just used the ones that happened to be with the gauge, I'm not surprised it leaked. If you didn't use washers at all .... (use a torque wrench; the spec torque is only 25 ftlbs; if you sheared a bolt you had to be way over that).

As you figured out, the most likely thing happening when you clamp the fuel return line is that you raise the rail pressure and are putting in too much fuel open-loop. My first guess is that all of time working on the truck with injectors not opening enough is that you moved the learned air-fuel setting all the way to rich. I believe that removing the EFI fuse will re-set the learned A/F; you'll need to drive it for a while to re-learn the correct setting.

#29

Registered User

Join Date: Mar 2008

Location: Temecula Valley, CA

Posts: 12,723

Likes: 0

Received 4 Likes

on

4 Posts

Only 30 seconds run time?

I could see that if the cold-start injector were being held open and flooding the engine. It should turn off as soon as you release the key, actually. That you can restart quickly sort of rules out flooding though.

30 seconds is also more than I'd expect from cold-start injector relay or AFM issues too- typically, those would die within a few seconds.

Pinching the fuel pressure return line keeps it running?

Then it does seem to be a flow thing. Could be restricted fuel pump inlet / strainer, restricted fuel filter or low voltage at the fuel pump... possibly a fuel hose inner liner has cracked and/or separated, or maybe a whole lot of sediment in the fuel tank getting stirred up by the fuel returning to the tank clogs the strainer and then settles shortly after the engine dies. allowing you to restart and repeat.

The pulsation dampener is exactly what it's name suggests: it dampens pulses in the fuel pressure to that the injectors see a mostly uniform fuel pressure and thus inject mostly equal amounts of fuel. It was mounted at the forward end of the fuel rail and deleted on later engines.

I could see that if the cold-start injector were being held open and flooding the engine. It should turn off as soon as you release the key, actually. That you can restart quickly sort of rules out flooding though.

30 seconds is also more than I'd expect from cold-start injector relay or AFM issues too- typically, those would die within a few seconds.

Pinching the fuel pressure return line keeps it running?

Then it does seem to be a flow thing. Could be restricted fuel pump inlet / strainer, restricted fuel filter or low voltage at the fuel pump... possibly a fuel hose inner liner has cracked and/or separated, or maybe a whole lot of sediment in the fuel tank getting stirred up by the fuel returning to the tank clogs the strainer and then settles shortly after the engine dies. allowing you to restart and repeat.

The pulsation dampener is exactly what it's name suggests: it dampens pulses in the fuel pressure to that the injectors see a mostly uniform fuel pressure and thus inject mostly equal amounts of fuel. It was mounted at the forward end of the fuel rail and deleted on later engines.

#31

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

The dampner has been removed on the newer models, just reduces pulsations.I believe the regulator is the one by the firewall. With the pinched return line, seems to me it is letting fuel pressure to build up to go out the injector as it should. Otherwise it is going to take the path of least resistance or in your case possibly no resistance.

abecedarian brought up a lot of good points as well. You dont by chance run your fuel extremely low do you? Once I hit the 1/4 mark I fill up. Fuel is also a coolant for the pump and wonder if your pump is just getting weak from getting hot.

These tanks do get in bad shape. I have had to clean several tanks and the build up is bad. If the sock at the end of the pump gets holes in it and pumps crud or gets a hard varnish that literally can seal the sock up and not let enough fuel into the pump.

If you do by chance have a fuel pump issue, Toyota wants around $300 for a fuel pump. The parts stores want $150ish. I have replaced 6 pumps on 6 different trucks and never an issue with them from ebay. I got them for about $30 each and you can save $5 if you call the seller, as he doesnt have to pay ebays fee and that was counting shipping. It looks identical as what is in your truck as well.

If you have a tank issue,in a nutshell, to clean my tanks, I fill them with vinegar and let them soak a few days and seal them with Red-Kote. It is impossible to get the rust dust ( looks like flour only red). Every build I have done has a bad tank here in the midwest. Most of the return lines and the pump holder lines has been clogged as well. Doesnt sound like your return line is clogged.

There is a metal line on your fuel pump bracket, be extremely careful when messing with it. That is a hard part and expensive part to find. Dont break the metal line. It likes to twist. Messing with fuel tanks and fumes are visible scares me. I prefer to do my tanks in the winter.

Sounds like you just need to go thru your fuel supply system and you will be up and running.

abecedarian brought up a lot of good points as well. You dont by chance run your fuel extremely low do you? Once I hit the 1/4 mark I fill up. Fuel is also a coolant for the pump and wonder if your pump is just getting weak from getting hot.

These tanks do get in bad shape. I have had to clean several tanks and the build up is bad. If the sock at the end of the pump gets holes in it and pumps crud or gets a hard varnish that literally can seal the sock up and not let enough fuel into the pump.

If you do by chance have a fuel pump issue, Toyota wants around $300 for a fuel pump. The parts stores want $150ish. I have replaced 6 pumps on 6 different trucks and never an issue with them from ebay. I got them for about $30 each and you can save $5 if you call the seller, as he doesnt have to pay ebays fee and that was counting shipping. It looks identical as what is in your truck as well.

If you have a tank issue,in a nutshell, to clean my tanks, I fill them with vinegar and let them soak a few days and seal them with Red-Kote. It is impossible to get the rust dust ( looks like flour only red). Every build I have done has a bad tank here in the midwest. Most of the return lines and the pump holder lines has been clogged as well. Doesnt sound like your return line is clogged.

There is a metal line on your fuel pump bracket, be extremely careful when messing with it. That is a hard part and expensive part to find. Dont break the metal line. It likes to twist. Messing with fuel tanks and fumes are visible scares me. I prefer to do my tanks in the winter.

Sounds like you just need to go thru your fuel supply system and you will be up and running.

#32

Registered User

Thread Starter

Join Date: Aug 2013

Location: Houston, TX

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

FIXED (EDIT: NOT FIXED, see 2016 post)

I spent a few hours in the shop last night getting trying to get another cheap FP kit (Autozone rental) to seal. I found that using the stock crush washers on the adapter and about 12 ft\lbs does the trick. I think anything over will shear those aluminum adapters. I will be ordering the FP kit from LCE.

Here's what I read:

- About 32 PSI while cranking and running. As the motor began to die the FP went up to about 38 PSI.

- I know this is a little low but the gauge looked a rough and I figured it wasn't completely accurate. Also, since the pressure was rising as it died I became more convinced that it wasn't a pressure problem.

-Clamped return line and fuel pressure rose to ~55PSI. Ran great.

-Loosened vise grip on return line to only restrict flow. This gave me a little over 40 PSI at the rail. Wouldn't run. I'm now convinced I don't have a fuel pressure problem.

Essentially, I kept asking myself: "why would over compensation on pressure enable the motor to run so smoothly?"

The day the runner broke down I had replaced the injectors (ran great), drove it about 20 miles to my destination and about 10 miles back to where it broke down. Since this was the last major change and I knew that I had spark, compression, fuel pressure, and noid lights verifying the injectors were being told to fire, I decided to just put the old injectors back in and see what happened. This fixed the problem.

I tested all of the "new" injectors (remans from AUS injection) as I pulled them out and all but 1 tested at 2.2 OHMS, the other tested at 2.4. I'm not quite sure why they would test fine, run fine at first, then later require an extra 20PSI to fire correctly, but something definitely isn't right.

No doubt that my original signal issue was due to weak wires at the factory splices, but at the end of the day, my major problem was the last thing I "fixed".

For now, I'm just going to keep running the old injectors and see what AUS injection will do on the remans. To be honest, I'm a little burned out.

Thanks again to everyone who helped. Hopefully I've picked up some valuable knowledge throughout this process and can return the favor sometime.

I spent a few hours in the shop last night getting trying to get another cheap FP kit (Autozone rental) to seal. I found that using the stock crush washers on the adapter and about 12 ft\lbs does the trick. I think anything over will shear those aluminum adapters. I will be ordering the FP kit from LCE.

Here's what I read:

- About 32 PSI while cranking and running. As the motor began to die the FP went up to about 38 PSI.

- I know this is a little low but the gauge looked a rough and I figured it wasn't completely accurate. Also, since the pressure was rising as it died I became more convinced that it wasn't a pressure problem.

-Clamped return line and fuel pressure rose to ~55PSI. Ran great.

-Loosened vise grip on return line to only restrict flow. This gave me a little over 40 PSI at the rail. Wouldn't run. I'm now convinced I don't have a fuel pressure problem.

Essentially, I kept asking myself: "why would over compensation on pressure enable the motor to run so smoothly?"

The day the runner broke down I had replaced the injectors (ran great), drove it about 20 miles to my destination and about 10 miles back to where it broke down. Since this was the last major change and I knew that I had spark, compression, fuel pressure, and noid lights verifying the injectors were being told to fire, I decided to just put the old injectors back in and see what happened. This fixed the problem.

I tested all of the "new" injectors (remans from AUS injection) as I pulled them out and all but 1 tested at 2.2 OHMS, the other tested at 2.4. I'm not quite sure why they would test fine, run fine at first, then later require an extra 20PSI to fire correctly, but something definitely isn't right.

No doubt that my original signal issue was due to weak wires at the factory splices, but at the end of the day, my major problem was the last thing I "fixed".

For now, I'm just going to keep running the old injectors and see what AUS injection will do on the remans. To be honest, I'm a little burned out.

Thanks again to everyone who helped. Hopefully I've picked up some valuable knowledge throughout this process and can return the favor sometime.

Last edited by huffman102833; 06-23-2016 at 07:40 AM.

#35

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

Injectors have a tiny screen/filter in the input. It is possible you had some dirt in the system that took a bit to get into the filter. Then more pressure was required to push the right amount of fuel through.

It's not really your problem now, but if you're curious a magnifying glass might tell you something interesting.

It's not really your problem now, but if you're curious a magnifying glass might tell you something interesting.

#36

Registered User

Thread Starter

Join Date: Aug 2013

Location: Houston, TX

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

I know this is an old thread, but I failed to write back on the continued problem and I think this might help someone who comes across the same issue in the future.

As you see from my last post, I thought the injector swap fixed this problem but it showed up again shortly after.

In short, my problem was a rusty fuel tank. My fuel pump filter wasn't able to filter out extremely fine rust particles, but the screen on the injectors did. The "new" injectors I originally installed were fine, just clogged. I assume that the old injectors had a higher tolerance since the screens were worn. Pinching off the return line seemed to remedy this problem because the increased pressure forced fuel through the injector screens.

New tank, filter, and injector cleaning fixed the problem. Anyone else with the same problem, I strongly encourage you to take a look at this before jumping through all the hoops that I did.

As you see from my last post, I thought the injector swap fixed this problem but it showed up again shortly after.

In short, my problem was a rusty fuel tank. My fuel pump filter wasn't able to filter out extremely fine rust particles, but the screen on the injectors did. The "new" injectors I originally installed were fine, just clogged. I assume that the old injectors had a higher tolerance since the screens were worn. Pinching off the return line seemed to remedy this problem because the increased pressure forced fuel through the injector screens.

New tank, filter, and injector cleaning fixed the problem. Anyone else with the same problem, I strongly encourage you to take a look at this before jumping through all the hoops that I did.

#37

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

Glad to see you updated the thread and let us know what was causing the issue. Just a follow up on your fuel problem. I see "Rusty" tanks all the time. What looks like rust in the tank is fuel additive build up inside the tank. I have cleaned several tanks and when I get them cleaned out, there is no pitting in the tanks, just shiney bare metal. I would suggest a new tank if you can afford one over cleaning one but cleaning works great in my opinion.

In each of my build threads, one of the first things I go thru is the fuel system. Inside the tank can look rusty and look terrible. The only rust I have had to deal with is when mud gets on top of a tank and causes rust holes in the top of the tank.

Pickups usually are the ones that will have rust holes in the top of the tank as the little shield Toyota uses to keep mud from slinging on top of the tank is not wide enough to prevent slinging.

4Runners fuel tanks have a lot more protection from mud getting slung on top of the tank and I have never dealt with a rust hole in the top of a tank like I have with pickups.

As you mentioned, the fuel filter can not catch all of the fine debris and can still clog fuel injectors. By the sound of how bad your fuel system was, I would be willing to bet your Return Line on the fire wall going all the way back to the Fuel Pump Brackets lines are clogged.

The way I unclog my Return line is to use a gear oil bottle lid as a mini funnel and fill the Return Line with Marvel Mystery Oil and let it soak its way thru the line. I use a low pressure air hose to help clear the line. This can be a slow process taking a week or so. In my opinion, getting the Return Line cleared helps take pressure off of the fuel pump. I have seen many of these trucks run just fine with a clogged Return Line so is not absolutely necessary to get to right away in my opinion. I would bet several people reading this trucks Return Lines are clogged.

In each of my build threads, one of the first things I go thru is the fuel system. Inside the tank can look rusty and look terrible. The only rust I have had to deal with is when mud gets on top of a tank and causes rust holes in the top of the tank.

Pickups usually are the ones that will have rust holes in the top of the tank as the little shield Toyota uses to keep mud from slinging on top of the tank is not wide enough to prevent slinging.

4Runners fuel tanks have a lot more protection from mud getting slung on top of the tank and I have never dealt with a rust hole in the top of a tank like I have with pickups.

As you mentioned, the fuel filter can not catch all of the fine debris and can still clog fuel injectors. By the sound of how bad your fuel system was, I would be willing to bet your Return Line on the fire wall going all the way back to the Fuel Pump Brackets lines are clogged.

The way I unclog my Return line is to use a gear oil bottle lid as a mini funnel and fill the Return Line with Marvel Mystery Oil and let it soak its way thru the line. I use a low pressure air hose to help clear the line. This can be a slow process taking a week or so. In my opinion, getting the Return Line cleared helps take pressure off of the fuel pump. I have seen many of these trucks run just fine with a clogged Return Line so is not absolutely necessary to get to right away in my opinion. I would bet several people reading this trucks Return Lines are clogged.

Thread

Thread Starter

Forum

Replies

Last Post

Jnkml

95.5-2004 Tacomas & 96-2002 4Runners

3

07-06-2015 01:20 PM

FS[SouthEast]: 1st Gen 4Runner Slider Window, Driver Side

coryc85

Misc Stuff (Vehicle Related)

0

07-06-2015 04:07 AM