3VZE Rebuilt Engine - Low Compression - WON'T START

#1

Registered User

Thread Starter

3VZE Rebuilt Engine - Low Compression - WON'T START

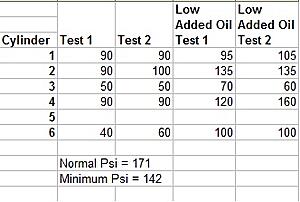

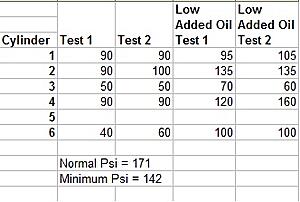

Recently rebuilt the 3vze in my 92 4Runner, but it won't start. After months of on and off fiddling and testing everything possible I decided to test the compression. (Didn't think it could possibly be the compression since it was just completely rebuilt..) The results speak for them self.

The FSM said that it could either be sticking valves or a problem with worn cylinders/rings. I'm pretty sure it isn't the cylinders or rings because I had them bored out and replaced with new pistons and rings. Although, as you can see from the picture, after adding oil upon suggestion from the manual the compression went up on half the cylinders. Still low, and not consistent.

The heads were cleaned and new valve seals were put on by the machinist while having my block bored. (In retrospect I should have had a complete valve job done.. lesson learned!)

So what do you guys think it could be?

If sticking valves, how would you check them and/or fix them?

Could the low compression be due to valve timing? Although I know for a fact that the camshafts are lined up with the crankshaft for the belt timing.

I've done all the work myself besides having the engine machined and would probably try to do the rest myself too. Any advantages taking it to a dealer for a valve tune up?

Didn't test cylinder 5 because it was a pain in the ass to reach and I couldn't connect the compression tester.

The FSM said that it could either be sticking valves or a problem with worn cylinders/rings. I'm pretty sure it isn't the cylinders or rings because I had them bored out and replaced with new pistons and rings. Although, as you can see from the picture, after adding oil upon suggestion from the manual the compression went up on half the cylinders. Still low, and not consistent.

The heads were cleaned and new valve seals were put on by the machinist while having my block bored. (In retrospect I should have had a complete valve job done.. lesson learned!)

So what do you guys think it could be?

If sticking valves, how would you check them and/or fix them?

Could the low compression be due to valve timing? Although I know for a fact that the camshafts are lined up with the crankshaft for the belt timing.

I've done all the work myself besides having the engine machined and would probably try to do the rest myself too. Any advantages taking it to a dealer for a valve tune up?

Didn't test cylinder 5 because it was a pain in the ass to reach and I couldn't connect the compression tester.

#2

3 and 6 are totally unacceptable and the rest are just plain bad for a new bore and pistons. If the valve timing is not off and Since it is a new bore, rings, and pistons, and assuming that you did not put the rings on upside down and you did stagger the ring split on the two rings top different then bottom, I would guess it is the heads. I would pull the heads and have them totally redone. Valves ground and replaced if needed and new guides and seals and resurfaced if needed. Be sure the heads are checked for cracks. If you tear it down I would also Mike the bores to see if the machine shop bored them correctly and mike the pistons to be sure they are correct.

Last edited by saved; 06-22-2011 at 02:59 PM.

#3

Short, neat, pretty, and sweet. You haven't broken-in the piston rings and cylinder walls. All compression tests are futile in determining the end results of a proper break-in procedure, until it's been completed. And since they're ALWAYS going to be higher if it was done correctly, you're in the clear there.

Why it won't start? Beats me sitting here, it's nothing you're thinking it might be IMO. I'll bet you money I could make it start if I were there though. Mine's never been able to stump me yet. And boy has it tried!

O.k., what's the first thing that's comes to mind from experience. Hmmm....VAFM connected? Probably wouldn't start if somebody left it unplugged. Could be A LOT of things though. Should you have paid for a COMPLETE valve job? NO. Odds are the intake valves and seats could've been lapped and re-used, but replacement of the exhaust valves and seats would've probably been a good idea in the long run. Again, from experience...

Why it won't start? Beats me sitting here, it's nothing you're thinking it might be IMO. I'll bet you money I could make it start if I were there though. Mine's never been able to stump me yet. And boy has it tried!

O.k., what's the first thing that's comes to mind from experience. Hmmm....VAFM connected? Probably wouldn't start if somebody left it unplugged. Could be A LOT of things though. Should you have paid for a COMPLETE valve job? NO. Odds are the intake valves and seats could've been lapped and re-used, but replacement of the exhaust valves and seats would've probably been a good idea in the long run. Again, from experience...

Last edited by MudHippy; 06-22-2011 at 05:05 PM.

#5

Registered User

Thread Starter

@Saved: Hmmm.. I sure hope I didn't put the rings on upside down, but the wide oil ring didn't look like it could go on wrong, and I made damn sure all my ring openings were on opposite corners. But other then that this is what I was thinking about doing since nothing else seems to be making sense.

@MudHippy: I'm glad someone knows what they are doing. lol but this is my first rebuild of the 3vze, although I've toyed with it a bunch on my dads old 90 4runner. The VAFM should be in working order. Everything was connected and I did the compression tests without it connected as the manual said to do. But other then that I've tested all the ignition setup, the VAFM, spart plugs, fuel lines, injectors were sent out and refurbished, timing belt and distributor was checked 2-3 times. So besides, fuel, air, spark, and timing.. the only thing I could think of for it not starting would be compression. And it doesn't seem to have any right now.

@The Man: Yes, it was honed when it was bored. Cylinders were nice, smooth, and oiled up before I installed the pistons.

I have to admit there are a ton of things it could be since I've torn it apart and replaced a bunch of parts. Just a few off the top of my head are the headers with LCE headers, the air intake with LCE air intake pipe with a K&N air filter, new wiring harness for my manual transmission (before the rebuild it had the old auto wiring harness for the auto that used to be in it, but it has had a manual tranny for many years. just wanted to fix the backup light and 4wd indicator problem), and a new ECU. Also, the piston and rings were from LCE. I've tested it with the new and old ECU, neither of which make a difference. No error codes because the thing hasn't started yet to give it the chance to store anything.

@MudHippy: I'm glad someone knows what they are doing. lol but this is my first rebuild of the 3vze, although I've toyed with it a bunch on my dads old 90 4runner. The VAFM should be in working order. Everything was connected and I did the compression tests without it connected as the manual said to do. But other then that I've tested all the ignition setup, the VAFM, spart plugs, fuel lines, injectors were sent out and refurbished, timing belt and distributor was checked 2-3 times. So besides, fuel, air, spark, and timing.. the only thing I could think of for it not starting would be compression. And it doesn't seem to have any right now.

@The Man: Yes, it was honed when it was bored. Cylinders were nice, smooth, and oiled up before I installed the pistons.

I have to admit there are a ton of things it could be since I've torn it apart and replaced a bunch of parts. Just a few off the top of my head are the headers with LCE headers, the air intake with LCE air intake pipe with a K&N air filter, new wiring harness for my manual transmission (before the rebuild it had the old auto wiring harness for the auto that used to be in it, but it has had a manual tranny for many years. just wanted to fix the backup light and 4wd indicator problem), and a new ECU. Also, the piston and rings were from LCE. I've tested it with the new and old ECU, neither of which make a difference. No error codes because the thing hasn't started yet to give it the chance to store anything.

#6

Contributing Member

Join Date: Apr 2006

Location: TENN Native Languishing in Virginia

Posts: 4,787

Likes: 0

Received 34 Likes

on

14 Posts

MAKE SURE you put the correct shims on the correct valves when the head was reassembled. If not, your valves aren't closing properly.

Also, since the cylinders were honed.....were over-standard size pistons/rings used?

Also, since the cylinders were honed.....were over-standard size pistons/rings used?

Last edited by TNRabbit; 06-23-2011 at 09:24 AM.

#7

Registered User

Thread Starter

@TNRabbit: That could very well be my problem. I had all the shims lined up and matched with each valve when I took it to the machinist but when I got it back they were all in a big bag.

Edit: Yes, I put .30 over sized pistons/rings in

Either I'm going to play hell trying to figure out which shim goes where or possibly tow it to a dealer

Any idea how much a toyota dealer would charge for valve adjustment/shimming?

Edit: Yes, I put .30 over sized pistons/rings in

Either I'm going to play hell trying to figure out which shim goes where or possibly tow it to a dealer

Any idea how much a toyota dealer would charge for valve adjustment/shimming?

Last edited by megaez; 06-23-2011 at 09:32 AM.

Trending Topics

#8

Contributing Member

You need fuel, air and spark to get it going.

Pull the cold start injector and see it it sprays while cranking.

Check for spark with a spark tester.

Your compression is probably not the reason it's failing to start.

Pull the cold start injector and see it it sprays while cranking.

Check for spark with a spark tester.

Your compression is probably not the reason it's failing to start.

#9

Registered User

@TNRabbit: That could very well be my problem. I had all the shims lined up and matched with each valve when I took it to the machinist but when I got it back they were all in a big bag.

Edit: Yes, I put .30 over sized pistons/rings in

Either I'm going to play hell trying to figure out which shim goes where or possibly tow it to a dealer

Any idea how much a toyota dealer would charge for valve adjustment/shimming?

Edit: Yes, I put .30 over sized pistons/rings in

Either I'm going to play hell trying to figure out which shim goes where or possibly tow it to a dealer

Any idea how much a toyota dealer would charge for valve adjustment/shimming?

Well that's going to be most of all of your issue there man! As for the dealer I donno what they'd charge for that. All I know is that it's going to be a pain in the arse to do.

I'm sure you could do it yourself it's going to be a lot of trial and error that's for sure. Good luck to ya! Maybe have the machinist do it since he mixed them up in the first place.

#10

Registered User

Thread Starter

@Marc: I've tested all those. There is fuel up to the cold start injector and under pressure. After cranking it half a billion times and thinking it was flooded. I took it out and there was fuel ever where. Could smell fuel on the spark plugs after pulling them. I could even see that fuel had gotten down into the intake manifold after taking it off to replace the knock sensor wire, thinking it was retarding my timing. I've checked the spark from the ignition coil through the distributor to the end of the plugs, and on a test spark plug.

#11

Registered User

Thread Starter

@Lumpy: Haha, yeah I'm not going back to that machinist. Dude told me it would be a week. After 3 weeks I was getting pissed so I think he rushed to get it done. I'm thinking I'll take the heads off again, get a full valve job done from a better engine mechanic/machinist then try to figure out my shims. Thanks for all the help guys!

#14

Registered User

Thread Starter

One other thing I found odd was that when I first tried starting it up it made a few *Puff sounds* from the tail pipe but ever since then it hasn't really made any noises besides the engine cranking.

Sound like the exhaust valves could be closed or stuck?

Sound like the exhaust valves could be closed or stuck?

#15

Registered User

Even if you were 180 out it would still fire once in a while...You'd get a hit here and there. I'm betting it's the valves.

Just to check spark pull a plug wire and stick a screwdriver in it and hold it against something metal. See a spark you know you have spark.

Even if you do have a spark with the compression being so low, valves being open, you may not get it to hit at all. Get a valve job and start over.

Just to check spark pull a plug wire and stick a screwdriver in it and hold it against something metal. See a spark you know you have spark.

Even if you do have a spark with the compression being so low, valves being open, you may not get it to hit at all. Get a valve job and start over.

#16

Registered User

iTrader: (1)

Could also be your heads are warped, #6 is notorious due to the exhaust manifold design. best bet now is to pull you heads off and take / ship to someone who is competant with the engine.

3 & 6 are at the back both heads may just be curling up.

Pull and check with a straight edge and feeler guages, they might even be twisted.

3 & 6 are at the back both heads may just be curling up.

Pull and check with a straight edge and feeler guages, they might even be twisted.

#18

Registered User

In saying that I like my 22re a bit more than my 3.0 but my 3.0 has not let me down and it's not seen good days with past owners.

#19

Registered User

Thread Starter

Lumpy is right, I've had no problems with my 3.slo besides it being slow and a bit lacking on power. But lets face it, the thing is near 20 years old and the previous owners had used it hard. (swapped transmissions on it, complete Jardin exhaust which is now replaced with LCE exhaust and Mangaflow muffler, and it had other mods before I bought it)

@skypilot:

the heads were resurfaced at the machinist and looked over for cracks and what not, and I had no problem with them before. Had a head gasket failure about a year into owning it (going on 7 years now) and its been fine. But I'll make sure to have it checked for warpage. Also I'm pretty sure the 3rd cylinder isn't at the back.

Back

5,6

3,4

1,2

Front

@jessed59:

I would have loved to have done a 3.4 swap and it almost happened with my sister totaling my dads 2000 4runner. But the insurance took it and we never saw it again.

.....BUT I'm hoping with this rebuild the 3.slo will have a new lease on life with the LCE headers, exhaust, and air intake system. :fingers crossed:

@skypilot:

the heads were resurfaced at the machinist and looked over for cracks and what not, and I had no problem with them before. Had a head gasket failure about a year into owning it (going on 7 years now) and its been fine. But I'll make sure to have it checked for warpage. Also I'm pretty sure the 3rd cylinder isn't at the back.

Back

5,6

3,4

1,2

Front

@jessed59:

I would have loved to have done a 3.4 swap and it almost happened with my sister totaling my dads 2000 4runner. But the insurance took it and we never saw it again.

.....BUT I'm hoping with this rebuild the 3.slo will have a new lease on life with the LCE headers, exhaust, and air intake system. :fingers crossed:

#20

Yeah, every other motor can go to hell as far as I care. I couldn't be more happy with it, suits my needs to a T. VIVA LA 3VZE!!!

I don't know what to think about your valve shim dilema. Do it yourself with the proper measuring equipment/tools is my suggestion, probably a lot cheaper that way(was for me). And then you know it's done right. But unless some of them are shimmed to the point that they can't close all the way, I don't see how it could cause a compression problem anyways. It certainly isn't going to affect the valve timing much, there's only going to be so much difference in shim thicknesses, and it ain't likely going to be a whole lot. So they might be closer to shimmed correctly than you think. Hell, you don't even know you got it wrong YET! Plus, like I'm saying, I'm pretty sure you'd have to degree the cams to change the valve timing significantly.

I forgot to mention the time I thought I had a burnt #6 exhaust valve(massive compression loss @ #6 cylinder), and it ended up being a cracked #6 piston. That was fun!

I don't know what to think about your valve shim dilema. Do it yourself with the proper measuring equipment/tools is my suggestion, probably a lot cheaper that way(was for me). And then you know it's done right. But unless some of them are shimmed to the point that they can't close all the way, I don't see how it could cause a compression problem anyways. It certainly isn't going to affect the valve timing much, there's only going to be so much difference in shim thicknesses, and it ain't likely going to be a whole lot. So they might be closer to shimmed correctly than you think. Hell, you don't even know you got it wrong YET! Plus, like I'm saying, I'm pretty sure you'd have to degree the cams to change the valve timing significantly.

I forgot to mention the time I thought I had a burnt #6 exhaust valve(massive compression loss @ #6 cylinder), and it ended up being a cracked #6 piston. That was fun!

Last edited by MudHippy; 06-23-2011 at 02:03 PM.