3vze code 52 troubleshooting

#1

Registered User

Thread Starter

3vze code 52 troubleshooting

1994 Toyota pickup 3.0l 3vze

Does anyone have the ECM pinouts, pigtail pinouts for the knock sensor/knock sensor pigtail/engine harness (where it plugs into the pigtail) wires and wire colors and any testing procedures for testing the circuit as a whole to include the sensor. I would like to test the continuity of the circuit as well as the sensor operation. I want to make sure it is the knock sensor and not the wiring before tearing the motor apart to replace the sensor.

Brief summary of issue - just replaced long block (replaced pigtail harness but not knock sensor) code 52 pops up after driving a couple miles and never goes off until reset, then stays off until I drive it again. Never comes on while idling/tuning only while driving.

Thanks

Does anyone have the ECM pinouts, pigtail pinouts for the knock sensor/knock sensor pigtail/engine harness (where it plugs into the pigtail) wires and wire colors and any testing procedures for testing the circuit as a whole to include the sensor. I would like to test the continuity of the circuit as well as the sensor operation. I want to make sure it is the knock sensor and not the wiring before tearing the motor apart to replace the sensor.

Brief summary of issue - just replaced long block (replaced pigtail harness but not knock sensor) code 52 pops up after driving a couple miles and never goes off until reset, then stays off until I drive it again. Never comes on while idling/tuning only while driving.

Thanks

#2

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,252

Likes: 0

Received 820 Likes

on

648 Posts

It's probably not the sensor (but you already figured that out). They are very tough.

The pigtail is black and brown; brown is the shield. The shield is NOT connected at the sensor, but is grounded in the ECU direction (at splice I1). The Knock Sensor (KNK) is connected to pin 5 (again, black) on connector E5 at the ECU (16-pin connector; I believe it's between the 22 and 26 pin connectors).

Code 52 is SUPPOSED to only come on while driving (actually, "With engine speed between 1,600 rpm – 5,200 rpm, signal from knock sensor is not input to ECM for 6 revolution. (KNK)" http://personal.utulsa.edu/~nathan-b...85diagnosi.pdf)

Good luck, and let us know what you find.

The pigtail is black and brown; brown is the shield. The shield is NOT connected at the sensor, but is grounded in the ECU direction (at splice I1). The Knock Sensor (KNK) is connected to pin 5 (again, black) on connector E5 at the ECU (16-pin connector; I believe it's between the 22 and 26 pin connectors).

Code 52 is SUPPOSED to only come on while driving (actually, "With engine speed between 1,600 rpm – 5,200 rpm, signal from knock sensor is not input to ECM for 6 revolution. (KNK)" http://personal.utulsa.edu/~nathan-b...85diagnosi.pdf)

Good luck, and let us know what you find.

#3

Registered User

Thread Starter

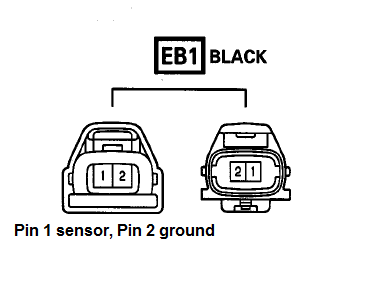

Thanks for the help, do you know what side of the engine side connecter the brown wire goes (where it plugs into the knock sensor pigtail) as you are looking at the pigtail connector socket with the connector release tab at the 12 o-clock position?? Here's a picture of the connector.

Last edited by moparbay; 09-09-2015 at 06:25 PM. Reason: to add image

#5

Registered User

Thread Starter

Well, I got a used connector with a length of factory wire cause i couldn't find the terminals for the connector. I went ahead and spliced it in and connected everything up and reset CEL. CEL came back on after running engine @ ~2000 rpms after about 15 seconds. Unhooked engine harness and checked continuity to the ECM connector. I had .9 ohms on both the signal and shield wire (terminates about 3-4 inches from the ECM with what looks to be like 2 other signal type cables and a green wire) from the engine harness connector (connecter that plugs into the knock sensor harness) and the plug that plugs into the ECM while wiggling the harness. I also tested for shorts and i am good there too. Since the knock sensor is new factory toyota part, i am assuming that is good as well. I tried measuring mV with the knock sensor plugged in and it hovered right around 1.3 mV with it running regardless of the engine rpm. I dont know if that is a valid test or what the values should be. I am going to buy a knock sensor and another harness (they are cheap enough) and plug them in and see if it trips the CEL. If it doesn't, i am going to assume the knock sensor is bad.

Does anyone have any different opinions? Thanks

Does anyone have any different opinions? Thanks

#6

Registered User

are you on ac or dc volts? the knock sensor sends power between "sensor" and ground to ensure the circuit is good, and to clean up the signal, but knocking is measured in ac voltage. a good meter should read hz, which i imagine is rpmx3. did you ohm the sensor, both at the plug and at the ecm connector with it plugged in? btw- the terminals should be available at a local truck repair shop/retailer, but you need the proper crimper and pin tooling.

#7

Registered User

Thread Starter

No, I did NOT ohm the sensor, only the harness where it connects to the knock sensor sub-harness. I believe I was using AC mV but would have to look at my meter to make sure. I have read/searched a lot of places and am under the assumption that the only way to test the sensor is with an oscilloscope which I do not possess. If you know of a way to test the sensor and know the limits/units I would sure give it a try. Thanks

Trending Topics

#8

Registered User

Thread Starter

Ok, so i installed my new (2nd one) knock sensor pigtail and new knock sensor and have mounted it to the rear lifting hook as a trouble shooting step and bam, CEL came on within seconds after raising the engine speed over 1600 rpm. i guess without any real trouble shooting steps with specifications, my only 2 option would be to replace the ecu and/or the entire signal wire running from the knock sensor pigtail to the ecu and replacing the ecu.

Does anyone have any actual trouble shooting steps for testing the signal wire and knock sensor and ecu?

I have ohm'd the signal wire from the knock sensor pigtail to the ecu and read .9 ohm on both the signal wire and the shield. Does anyone know how i can either eliminate the ecu or confirm that it is a ecu problem.

I do not want to cut the wire at the ecu plug just so i can run a new wire just as a troubleshooting step and i hate throwing parts at it blindly.

Does anyone have any actual trouble shooting steps for testing the signal wire and knock sensor and ecu?

I have ohm'd the signal wire from the knock sensor pigtail to the ecu and read .9 ohm on both the signal wire and the shield. Does anyone know how i can either eliminate the ecu or confirm that it is a ecu problem.

I do not want to cut the wire at the ecu plug just so i can run a new wire just as a troubleshooting step and i hate throwing parts at it blindly.

Last edited by moparbay; 09-23-2015 at 04:09 PM.

#9

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,252

Likes: 0

Received 820 Likes

on

648 Posts

Personally, I don't believe that mounting the knock sensor to the lifting hook works at all. So if that's where you put your test knock sensor, I'm not surprised you got the code.

There are 1 or 2 on this site who have claimed to resolve a Code 52 issue with the knock sensor on the lifting hook. It just makes no sense to me. Why would Toyota "hide" the knock sensor if putting it out there would work?

There are 1 or 2 on this site who have claimed to resolve a Code 52 issue with the knock sensor on the lifting hook. It just makes no sense to me. Why would Toyota "hide" the knock sensor if putting it out there would work?

#10

Registered User

Thread Starter

Personally, I don't believe that mounting the knock sensor to the lifting hook works at all. So if that's where you put your test knock sensor, I'm not surprised you got the code.

There are 1 or 2 on this site who have claimed to resolve a Code 52 issue with the knock sensor on the lifting hook. It just makes no sense to me. Why would Toyota "hide" the knock sensor if putting it out there would work?

There are 1 or 2 on this site who have claimed to resolve a Code 52 issue with the knock sensor on the lifting hook. It just makes no sense to me. Why would Toyota "hide" the knock sensor if putting it out there would work?

I understand the relocation of of the knock sensor is not advisable. I only did so as a troubleshooting step to to try an verify the knock sensor was bad without spending the better part of a day gaining access to the proper mounting location just to replace something that may/may not be the cause of the issue. I am not trying to resolve the issue by relocating the knock sensor, i am just trying to figure out what the issue is so i can fix it properly.

Does anyone have any "Actual" troubleshooting steps for code 52?? I have read portions of the FSM that everyone always mentions in these threads, but there are no actual procedures to undertake to determine the cause, all it says is what it could be, but nothing about how to test for the cause. This is my first toyota and my wrenching background is with pre-computer vehicles and need help from anyone willing to offer it up as i cant afford to take it to the dealer.

How do the toyota dealership techs trouble shoot this issue??

Maybe i am asking the wrong question..

How would you troubleshoot your 3vze truck if you were getting a code 52???

#12

Registered User

Thread Starter

1.1 ohms. my meter and leads are 17 years old. What's interesting even though my leads measure 1.1 ohms, ecm plug to the end of the engine harness is only .9 ohms for both the signal and shield wires. I get infinite reading when testing the signal to shield on both ends of the harness.

#13

Registered User

1.1 ohms. my meter and leads are 17 years old. What's interesting even though my leads measure 1.1 ohms, ecm plug to the end of the engine harness is only .9 ohms for both the signal and shield wires. I get infinite reading when testing the signal to shield on both ends of the harness.

#14

Registered User

Thread Starter

Yeah, the meter is a blue point i bought in '96-'98 and had to replace the leads. think the leads don't quite make good enough contact with the meter. Maybe it time to buy a new meter and test again. Do you know what i should see at the end of the engine harness at the knock sensor with the engine running?

#15

I had code 52 when I bought my 934r last year. Went round and round reading lots of threads, ohming out wires, even put an Oscope on it, replaced wire and mounted KS external all to no avail. Save yourself some headaches and just tear it apart and replace it AND the pigtail, which is what I finally did.

#16

Registered User

Thread Starter

Ok, I am tired of dealing with this POS so I take it to a Toyota dealer. They say it is the signal wire. They say they can't fix it because they would have to replace the entire engine harness and the harness is no longer available. They also said they have not seen anyone successfully splice the signal wire and would not attempt even if they could find the right wire. So, $80 down the drain.

Can anyone know what kind of wire I need and where to get it(I would rather not use coax for cable tv, Something that is similar in size as the original.). I do not have a radio shack near me.

Also, can anyone explain in detail (with pics if available) how to spice the new wire in? I thought a did a pretty good job and the dealer said what I did would not work. I am at your mercy. thanks

Can anyone know what kind of wire I need and where to get it(I would rather not use coax for cable tv, Something that is similar in size as the original.). I do not have a radio shack near me.

Also, can anyone explain in detail (with pics if available) how to spice the new wire in? I thought a did a pretty good job and the dealer said what I did would not work. I am at your mercy. thanks

Last edited by moparbay; 09-25-2015 at 09:44 AM.

#17

Registered User

Thread Starter

I think i found some cable. Will RJ58 cable work?? So now, i just need to replace the cable. It sounds super easy but are there any pitfalls to splicing the signal wire at the ecu plug and the plug that plugs into the knock sensor pigtail. I can't believe the toyota dealer is unwilling to do this.

#18

One of the things I tried was use some shielded wire, spliced approx 3in at ECU, ran to KS connector. Still did no good. I doubt seriously if the wire is bad. More likely the dealer knows more crap is likely to break when they start to tear into it. Even though it seemed like a PITA, I went ahead and tore mine apart and replaced the KS and pigtail. While in there I tested, cleaned, and rebuilt the injectors, did the valves, new valve cover gaskets, timing belt and associated goodies, replaced injector connectors, etc.

My thinking, if I'm going to tear it apart to replace that KS, might as well do as much as I can so I don't have to repeat a lot of the work later. 4r was in my garage a couple weeks, but I'm happy with the results....and no more code 52.

My thinking, if I'm going to tear it apart to replace that KS, might as well do as much as I can so I don't have to repeat a lot of the work later. 4r was in my garage a couple weeks, but I'm happy with the results....and no more code 52.

#19

Registered User

Thread Starter

Ok, after getting truck back from dealer, which the tech said there was a short in the KN signal wire, i did some more testing. if you test resistance between the 2 terminals with the ecu plugged in, you get 3.29 Kilo-Ohms, if you unplug the ecu, i get infinite resistance. Its my understanding that every circuit will have a path to ground (It has to or it will not work, the principle of electricty is based on this) and there for with have some level of continuity if the circuit includes a ground connection (Shield wire)

Does anyone know what the resistance should be be through the ks signal wire circuit with the ecu connected or can someone test their 94 3vze M/T 4x4 truck? Just unhooked the engine harness where it pluggs into the KS pigtail and run a OHM test between the 2 terminals with the key in the off position. Should take 5 minutes? this would really help me in determining my next step, ecu or KS. thank you.

Does anyone know what the resistance should be be through the ks signal wire circuit with the ecu connected or can someone test their 94 3vze M/T 4x4 truck? Just unhooked the engine harness where it pluggs into the KS pigtail and run a OHM test between the 2 terminals with the key in the off position. Should take 5 minutes? this would really help me in determining my next step, ecu or KS. thank you.

#20

Registered User

Thread Starter

I have run every Ohm test on the KS circuit that i can think of. I really do not think it is the Signal wire to from the KS to the ECU. I can post my results if anyone would like to see them or is interested in what they are. Just let me know and i will through them up here. There are quite a few of them.

Also, i did buy some RG 58 wire as i was going to run a new wire but after my latest round of testing, i decided it was not needed. I did ohm the new wire as a baseline, 29 feet of RG-58 (the store gave me the remainder of their roll for the price of 10 feet). the wire on the truck actually tested with lower Ohm readings then the new wire did.

Thanks again for the people who has responded.

Also, i did buy some RG 58 wire as i was going to run a new wire but after my latest round of testing, i decided it was not needed. I did ohm the new wire as a baseline, 29 feet of RG-58 (the store gave me the remainder of their roll for the price of 10 feet). the wire on the truck actually tested with lower Ohm readings then the new wire did.

Thanks again for the people who has responded.