22re not running questions

#1

22re not running questions

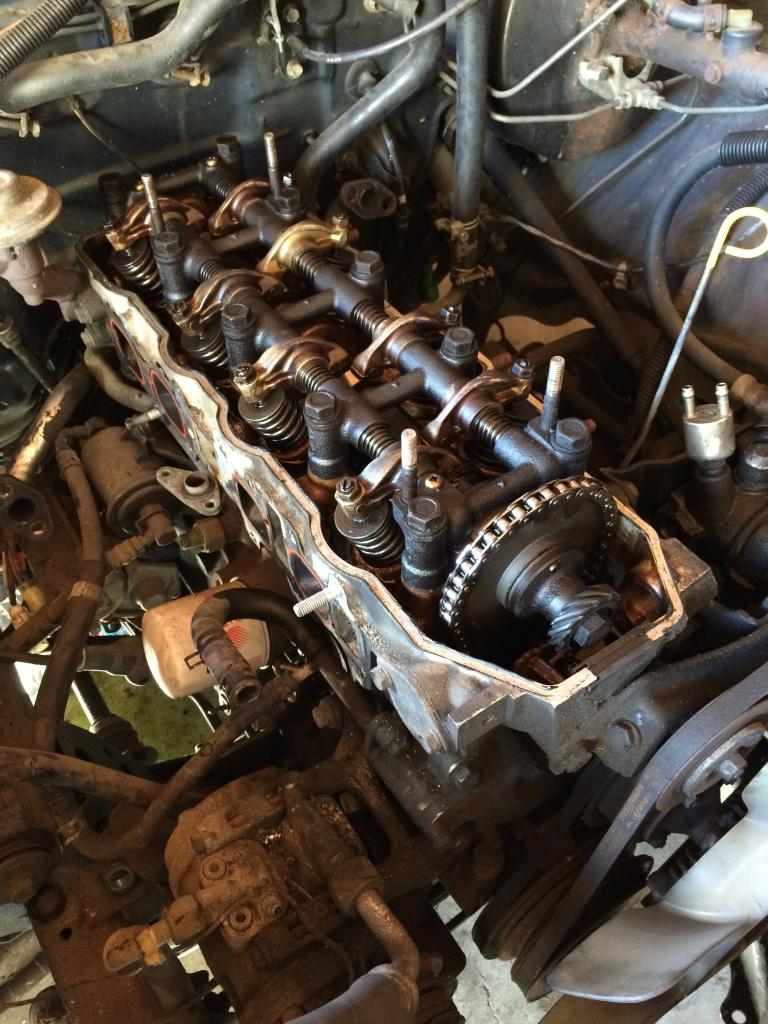

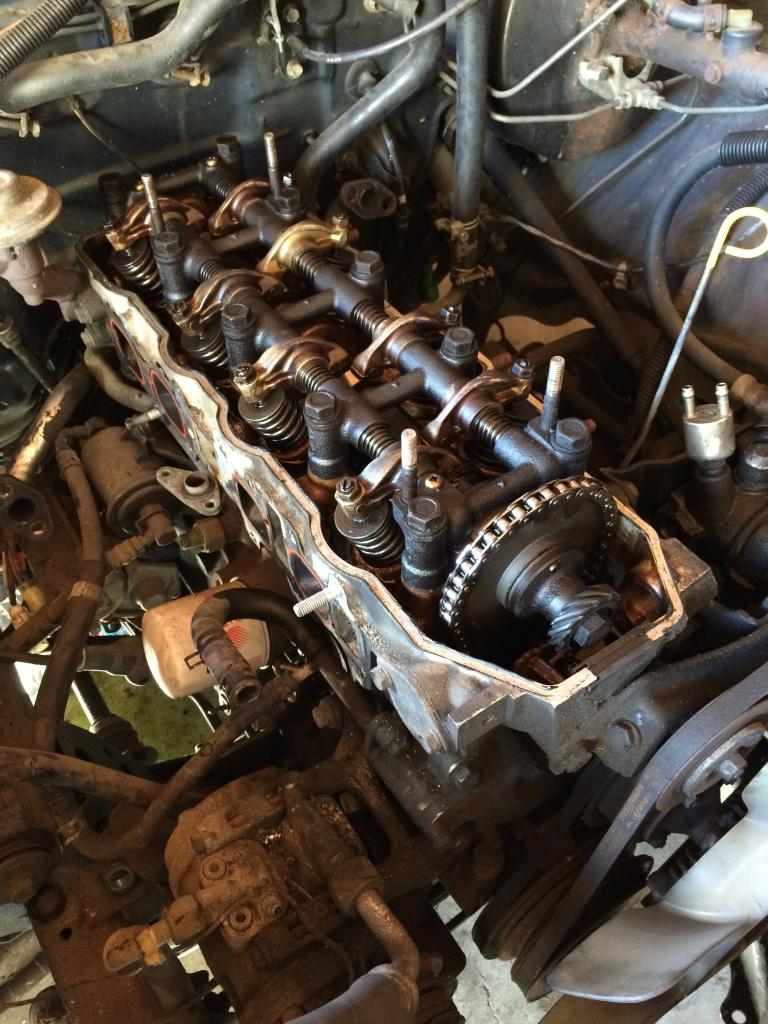

Hey hows it going guys I just bought a 1988 Pickup with a 22re in it. I bought it for cheap. It does not run its getting fuel and spark with low compression sounds weak when you turn it over. There was hardly any coolant in the radiator and P/O said it was over heated. So what am I looking for when I pull the motor apart.. Warped head, pistons, bent valves? What would you suspect i guess is what im saying.

Ive gotten most of the motor apart but stopped cause im at my parents house for the weekend. From where im at whats the best way to get the rest of the head off? Timing chain and tensioners look good so im gonna leave it for now. do I just pull the distributor drive nut off and then head bolts or what? Do I need to be at TDC for cy1? how do i line that up

Thanks guys from what ive read this is a very helpful forum. Im very excited about my new purchase (as soon as i get it running its getting a paint job)

(as soon as i get it running its getting a paint job)

Ive gotten most of the motor apart but stopped cause im at my parents house for the weekend. From where im at whats the best way to get the rest of the head off? Timing chain and tensioners look good so im gonna leave it for now. do I just pull the distributor drive nut off and then head bolts or what? Do I need to be at TDC for cy1? how do i line that up

Thanks guys from what ive read this is a very helpful forum. Im very excited about my new purchase

(as soon as i get it running its getting a paint job)

(as soon as i get it running its getting a paint job)

Last edited by andrewtexas123; 02-14-2015 at 05:35 PM.

#2

Registered User

iTrader: (1)

Pull the motor completely out. The take the head and block in for testing. Don't get the head milled. If it's warped just buy a new one from engnbldr. About the same price as a test deck and flush. Might not even test your current one if it over heated. Take the block and timing chain cover in at the same time and get them decked of needed. Not more than 10 thousandths at the most. Should only need like 4-5 thousandths. We hope. Then get your crank inspected. Maybe have the cylinders bored. Order a rebuild kit from engnbldr. And start wrenching. Also get new head bolts every time you do a head gasket. Just cheap piece of mind

#4

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

You can do the head with it in the engine bay but your back will thank you if you pull the motor. I have the Factory Service Manual and a Haynes Manual. I have compared both of them for a top end rebuild and they are the same. FSM is a little better for a complete overhaul but not by much in my opinion. The quick and easiest is to get a Haynes for about $20 and I suggest staying away from Chilton Manual.

While you still can, I would get a tool setup and use the starter to break the crankshaft bolt loose. If you are going to at least do the head, do the Timing Chain as well and you need the crankshaft pulley off for that. If you pull the motor then you can get an impact wrench to break the crankshaft bolt loose. It is tight!!!

A top rebuild isn't as quick as you may think. Being a two wheel I just pull the tranny with the motor. Easier to connect the tranny, just how I do it.

While you still can, I would get a tool setup and use the starter to break the crankshaft bolt loose. If you are going to at least do the head, do the Timing Chain as well and you need the crankshaft pulley off for that. If you pull the motor then you can get an impact wrench to break the crankshaft bolt loose. It is tight!!!

A top rebuild isn't as quick as you may think. Being a two wheel I just pull the tranny with the motor. Easier to connect the tranny, just how I do it.

Last edited by Terrys87; 02-14-2015 at 11:38 PM.

#5

Thanks for the responses!! So basiclly even if I find a warped head and replace it there is more then likely going to be more damage in the bottom end?

I completely agree I have it torn down this far why not run through the rest of the motor. But I don't want to do more work then necessary you know.

One more question i have read alot about getting the crankshaft bolt off with the starter but how about reinstalling it how do you effectively torque it back down?

Thanks, Andrew

I completely agree I have it torn down this far why not run through the rest of the motor. But I don't want to do more work then necessary you know.

One more question i have read alot about getting the crankshaft bolt off with the starter but how about reinstalling it how do you effectively torque it back down?

Thanks, Andrew

#7

Trending Topics

#8

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,252

Likes: 0

Received 820 Likes

on

648 Posts

"Blueprinting" an engine is really nice, but you're putting it back into a 27-year old vehicle, the attraction for which was that it was 'cheap.' I think the trick is to figure out just how much money to put in it so you're not wasting it.

Last edited by scope103; 02-15-2015 at 02:35 PM.

#9

Registered User

iTrader: (1)

This site is all about learning to take care of our rigs. Not sure where you got "blueprinting" an engine from. Don't recall reading that. Buying a "rebuilt" motor can be a roll of the dice as far as quality. Some of the cheaper ones are just that cheap. You could easily spend $2000 on a complete rebuild with install. With pricing all new parts and reusing the timing cover and block my rebuild is going to cost me around $1000. Thats an extra $1000 in my pocket for other upgrades. The OP has the motor fairly far torn down. If you pull the motor and put it on a stand its not really any harder than what the OP has done. I agree that renting a cherry picker twice is not cost effective. But you can buy one used usually with a engine stand in tow for under $200. Use it and then sell it for about the same. We can all agree to disagree if need be.

#10

A trick to torquing the crank bolt without the engine turning: Pull the starter out and have someone with a long screwdriver or prybar placed between one of the flywheel teeth and the bellhousing, in a way that won't bend anything. And don't torque it down with an impact, just because they might only have 125 ft lbs of torque doesn't mean it won't snap a camshaft that has a 300 ft lb torque spec.

#11

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,252

Likes: 0

Received 820 Likes

on

648 Posts

Every method involves some risk, so consider them all, keep the risks in mind, and be careful.

#13

Thanks for all the great Ideas on removing ths crank shaft bolt!

My next questions would be..

1. how can I tell or is there any tests to do to see if the block in fact needs to be rebuilt?

2. When I remove my head does the chain need to be at TDC? and does it slip over the chain sprocket?

3. does the haynes repair manual have info on tearing the motor apart?

I just want to get my truck running. Thanks again

-Andrew

My next questions would be..

1. how can I tell or is there any tests to do to see if the block in fact needs to be rebuilt?

2. When I remove my head does the chain need to be at TDC? and does it slip over the chain sprocket?

3. does the haynes repair manual have info on tearing the motor apart?

I just want to get my truck running. Thanks again

-Andrew

#14

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

I have done several top end rebuilds and had great luck with them. You will need to do a good compression test. Several different checks you can do to find out where it is losing compression. A Manual will tell you what all is needed to do to rebuild a motor. It will need to go a machine shop. If you just do the head and/or the block. Personally if I can afford to buy a rebuilt motor, I find it cheaper in the long run but rebuilding one slowly, I can do a piece at a time. Get the block to the shop, order parts so fourth. Not so much out at one time.

I use the starter trick as I have never had a bolt not to come out. The first 22re I rebuilt, I had a breaker bar, with about 5 foot of cheater bar on it. Transmission in first gear, tire blocked, and a chain vise on the flywheel and still could not get it. I have had two other motors where an impact and 3/8th inch air hose would not break it loose. It took a 1/2 inch air hose to break them loose. I use a torque wrench to reinstall them but I think when the bolt is in the crankshaft, that sometimes it just seizes in the crank. They can be a real bear to get out.

I like to set mine at TDC when doing a head gasket but it is not important until you reassemble it and then you will need it at TDC. Here is a thread that can give you an idea of what you need to do. https://www.yotatech.com/forums/f116...cement-212688/

I have done several 22re motors and still use a manual, you will need one. The torque specs in manuals for the head bolt is changed from what it says in the manual. Seems to me the manual says 62 foot pounds and it is actually 68 foot pounds. I could be wrong on the numbers and have it wrote in my manual which is not with me at this time. Someone will post it for you when needed.

If just doing the head I allow 3 days just to get it done. Pulling the head and taking it to the shop, cleaning will take that long. If rebuilding a motor, I allow a month. Not hard to do but machine work, ordering parts and assembling takes a while. If block and parts are all done, I can assemble a motor in a day but I think a month is a good guesstimate on the amount of time you are going to need. None of it happens over nite. Just my experience.

I use the starter trick as I have never had a bolt not to come out. The first 22re I rebuilt, I had a breaker bar, with about 5 foot of cheater bar on it. Transmission in first gear, tire blocked, and a chain vise on the flywheel and still could not get it. I have had two other motors where an impact and 3/8th inch air hose would not break it loose. It took a 1/2 inch air hose to break them loose. I use a torque wrench to reinstall them but I think when the bolt is in the crankshaft, that sometimes it just seizes in the crank. They can be a real bear to get out.

I like to set mine at TDC when doing a head gasket but it is not important until you reassemble it and then you will need it at TDC. Here is a thread that can give you an idea of what you need to do. https://www.yotatech.com/forums/f116...cement-212688/

I have done several 22re motors and still use a manual, you will need one. The torque specs in manuals for the head bolt is changed from what it says in the manual. Seems to me the manual says 62 foot pounds and it is actually 68 foot pounds. I could be wrong on the numbers and have it wrote in my manual which is not with me at this time. Someone will post it for you when needed.

If just doing the head I allow 3 days just to get it done. Pulling the head and taking it to the shop, cleaning will take that long. If rebuilding a motor, I allow a month. Not hard to do but machine work, ordering parts and assembling takes a while. If block and parts are all done, I can assemble a motor in a day but I think a month is a good guesstimate on the amount of time you are going to need. None of it happens over nite. Just my experience.

Last edited by Terrys87; 02-15-2015 at 11:56 PM.

#15

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,252

Likes: 0

Received 820 Likes

on

648 Posts

#16

Registered User

Join Date: Jul 2012

Location: Northern Colorado

Posts: 1,776

Likes: 0

Received 109 Likes

on

81 Posts

Just an observation. If you use the "transmission in gear" approach, you want the tranny in 5th, not 1st. You want the engine to have the least amount of mechanical advantage to the wheels as possible, so the wheels don't turn. Applying 150 ft-lbs of torque to the crankshaft in first gear translates to about 2500 ft-lbs at the wheels, which is going to be hard to hold even with full brakes. Shifting to 5th cuts that to about 500 ft-lbs; much easier to keep the vehicle from moving.

#19

Thanks for all the great information guys!!!

So I took the timing chain off, the power steering pump/bracket, 8 head bolts and the little bold on the front of the head. And the head is stuck on there

Are there any bolts or brackets on the back of the head that I am missing. I wedged a flat head in between the gasket in the front and got a little wiggle but i dot want to damage the block.

Any suggestions???

So I took the timing chain off, the power steering pump/bracket, 8 head bolts and the little bold on the front of the head. And the head is stuck on there

Are there any bolts or brackets on the back of the head that I am missing. I wedged a flat head in between the gasket in the front and got a little wiggle but i dot want to damage the block.

Any suggestions???

#20

Registered User

iTrader: (1)

Thanks for all the great information guys!!!

So I took the timing chain off, the power steering pump/bracket, 8 head bolts and the little bold on the front of the head. And the head is stuck on there

Are there any bolts or brackets on the back of the head that I am missing. I wedged a flat head in between the gasket in the front and got a little wiggle but i dot want to damage the block.

Any suggestions???

So I took the timing chain off, the power steering pump/bracket, 8 head bolts and the little bold on the front of the head. And the head is stuck on there

Are there any bolts or brackets on the back of the head that I am missing. I wedged a flat head in between the gasket in the front and got a little wiggle but i dot want to damage the block.

Any suggestions???

Rap with a dead blow hammer, maybe just be obstinate.